Method for preparing diaminonaphthalene by catalytic hydrogenation of dinitronaphthalene

A technology of dinitronaphthalene catalysis and diaminonaphthalene, which is applied in the preparation of amino compounds, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of large catalyst consumption and low product yield, and reduce catalyst consumption, The effect of increasing the conversion rate and improving the activity of the catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

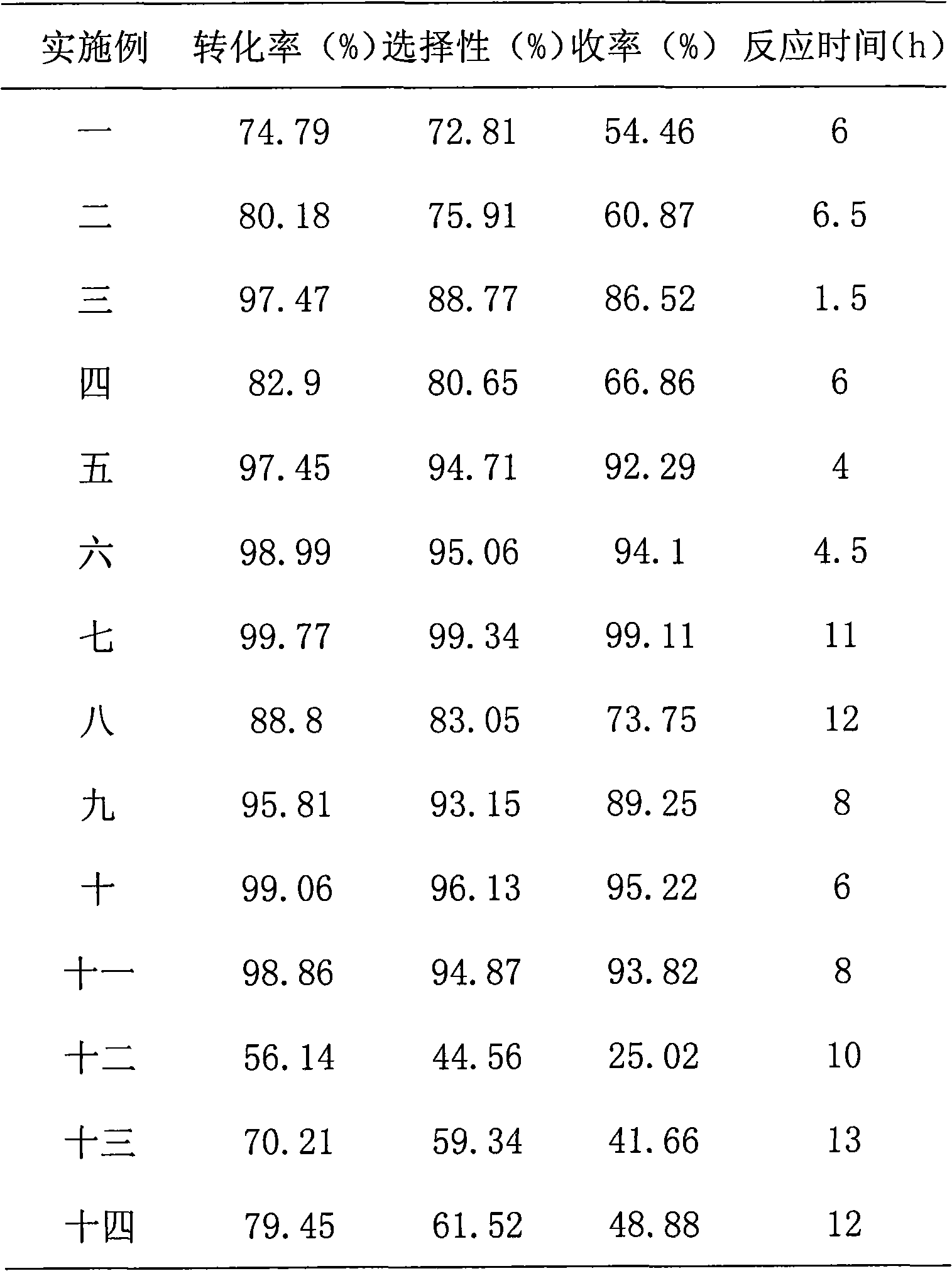

Examples

Embodiment 1

[0020] In a stirred stainless steel autoclave, add 0.5% Pd / activated carbon catalyst 0.02g (carrier activated carbon without pretreatment), 1,8-dinitronaphthalene 2g, isopropanol 40ml, close the autoclave, and replace with nitrogen Air in the reactor for three times, then replace the nitrogen in the reactor with hydrogen for three times and keep the pressure in the reactor, raise the temperature to 90°C, fill in hydrogen to make the reaction pressure to 4MPa, start stirring, keep the temperature until the pressure no longer drops , the reaction solution was taken out, the catalyst was removed by filtration, and the filtrate was analyzed by liquid chromatography.

Embodiment 2

[0022] In a stirred stainless steel autoclave, add 5% Pd / activated carbon catalyst 0.02g (carrier activated carbon without pretreatment), 1,5-dinitronaphthalene 2g, isopropanol 40ml, close the autoclave, and replace with nitrogen Air in the reactor for three times, then replace the nitrogen in the reactor with hydrogen for three times and keep the pressure in the reactor, raise the temperature to 90°C, fill in hydrogen to make the reaction pressure to 4MPa, start stirring, keep the temperature until the pressure no longer drops , the reaction solution was taken out, the catalyst was removed by filtration, and the filtrate was analyzed by liquid chromatography.

Embodiment 3

[0024]In a stirred stainless steel autoclave, add 0.02g of 5% Pd / mesoporous carbon catalyst (the carrier mesoporous carbon is not pretreated), 2g of 1,8-dinitronaphthalene, 40ml of isopropanol, and close the reactor , Replace the air in the reactor with nitrogen three times, then replace the nitrogen in the reactor with hydrogen three times and keep the pressure in the reactor, raise the temperature to 90°C, fill in hydrogen to make the reaction pressure to 4MPa, start stirring, and keep the temperature until the pressure Take out the reaction liquid until it no longer drops, remove the catalyst by filtration, and analyze the filtrate by liquid chromatography.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com