Technical method for continuously producing fatty glyceride and special equipment thereof

A technology of fatty acid glycerides and process methods, which is applied in the field of continuous production of fatty acid glycerides and its special equipment, can solve the problems of inability to realize continuous automatic large-scale production, complicated and uneconomical production process, etc., and achieve large-scale Large-scale continuous production, accelerated esterification reaction speed, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

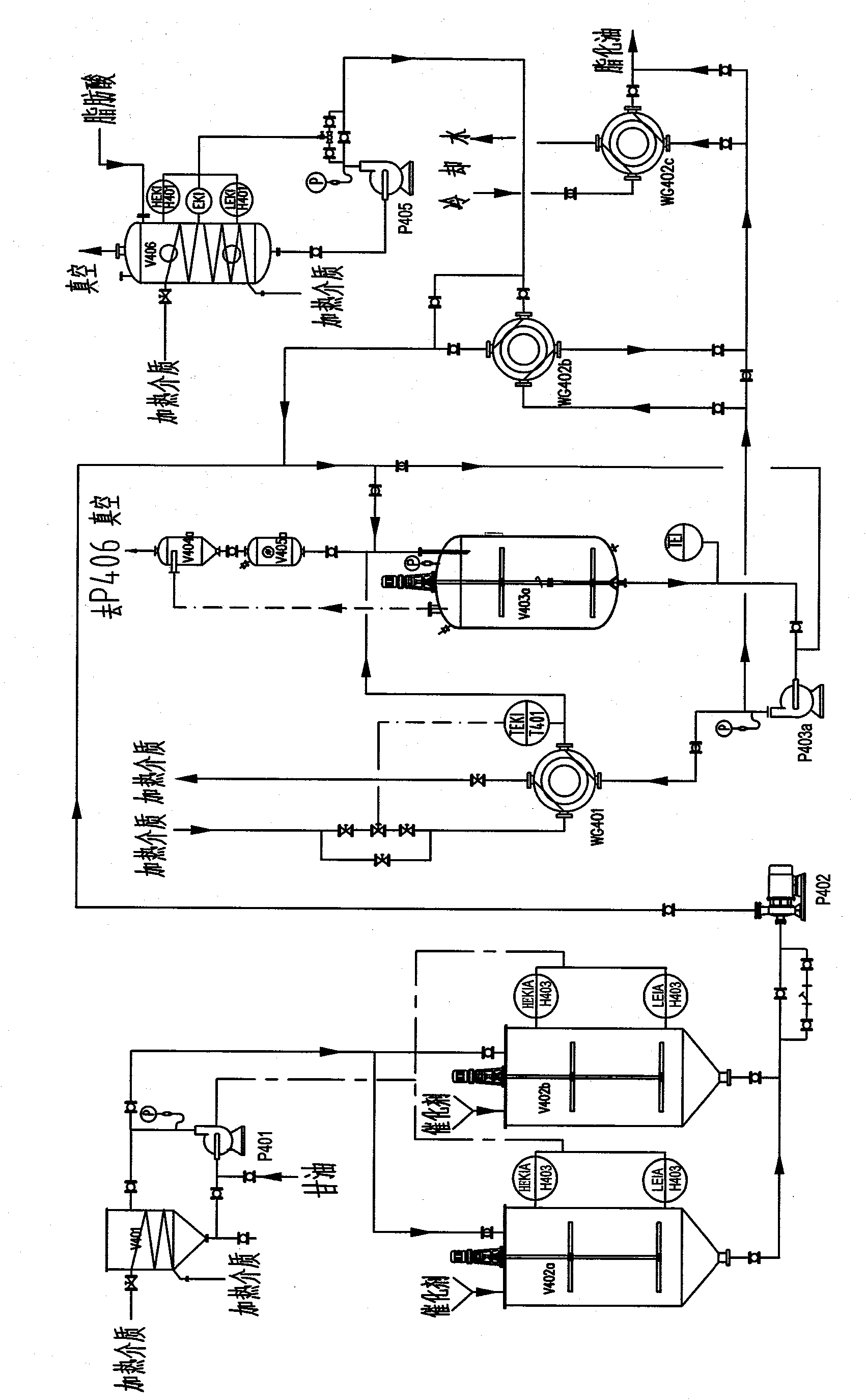

[0023]Embodiment 1: Referring to Fig. 1, in the figure, the fatty acid is preheated in the fatty acid temporary storage tank V406, sent to the primary heat exchanger WG402b by the fatty acid delivery pump P405 for preheating again, and finally sent to the esterification reactor V403a. Glycerin is transported from the storage tank V401 to the catalyst temporary storage tank V402 by the pump P401, and the catalyst is added into the catalyst temporary storage tank V402 for stirring, so that the glycerin and the catalyst are fully mixed. The mixed glycerin is added to the esterification reactor V403a through the quantitative pump P402 for reaction. In order to fully carry out the reaction, the esterification reactor V403a is equipped with a stirring device, and the stirring speed is generally 40-150rpm. The water produced by the reaction is removed from the reaction system through the vacuum system P406, so that the reaction can be carried out completely. Part of the fatty acid e...

Embodiment 2

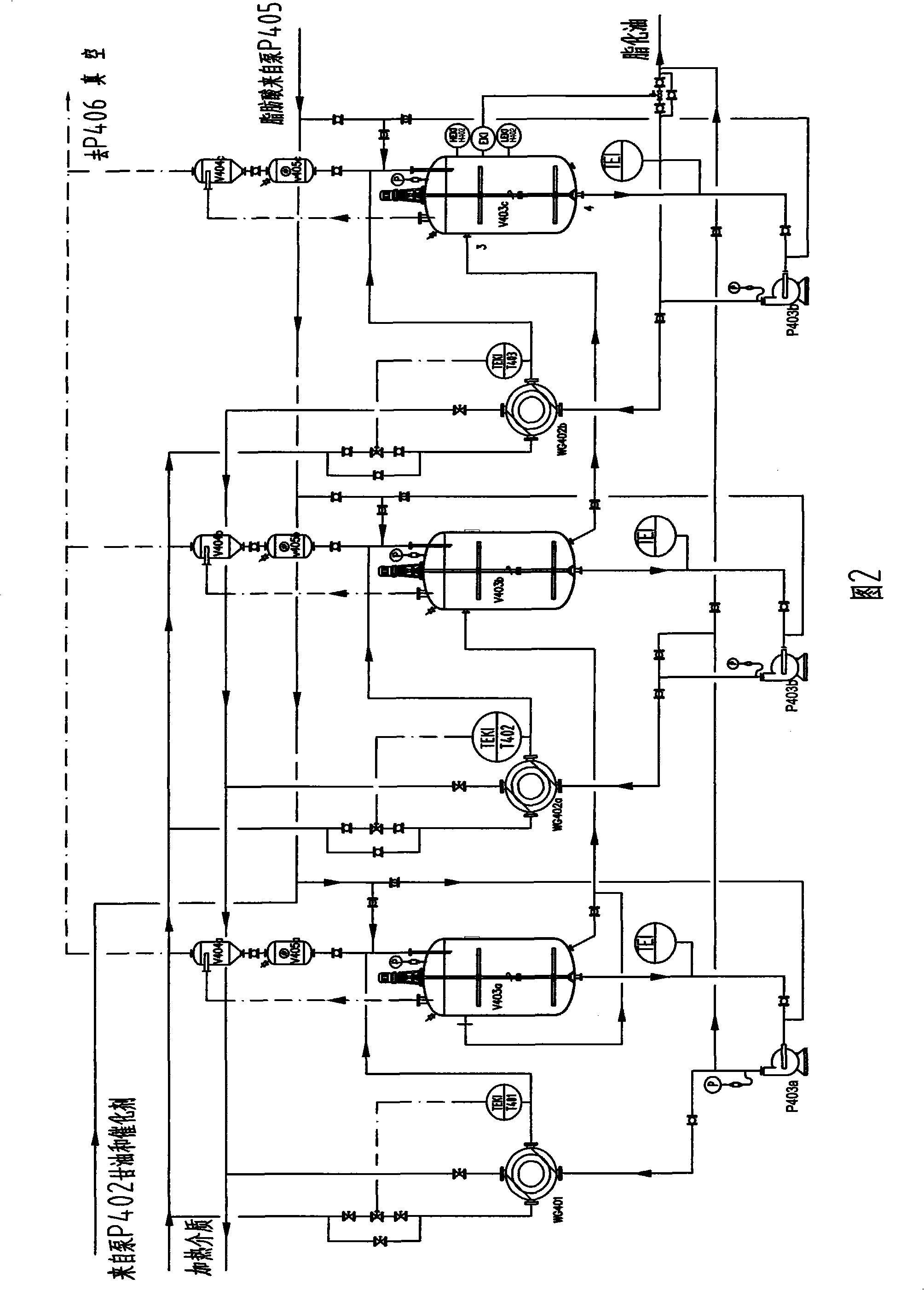

[0027] Embodiment 2: Referring to Fig. 2, the number in the figure is the same as that of Embodiment 1, and the representative meaning is the same. The fatty acid passes through the pump P405, and the glycerin mixed with the catalyst is continuously added to the first group of esterification reaction system V403a by the pump P402 for reaction. After reaching the height of the liquid level of the reaction kettle V403a, it flows into the next esterification reaction system V403b through the overflow pipe, and the liquid level of the esterification reaction kettle V403b flows into the next esterification reaction system V403c through the overflow pipe after reaching the set height. In this way, a series of multiple reaction systems are formed (three in the figure, and different numbers of series can be used as required). Generally, the liquid level is controlled by the last reaction system reactor (for example, H402 of V403c). Of course, each reaction system can also be individual...

Embodiment 3

[0028] Embodiment 3: This embodiment is basically the same as Embodiment 2, and the similarities will not be repeated. The difference is that multiple reaction systems can be connected in parallel, and different numbers of parallel connections can be used as required to realize large-scale continuous production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com