Method and device for inspecting abnormal data

A technology of abnormal data and inspection method, which is applied in the field of abnormal data inspection, can solve problems such as complex algorithms and inapplicability to actual production, and achieve the effects of improving product yield, reducing scrap, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

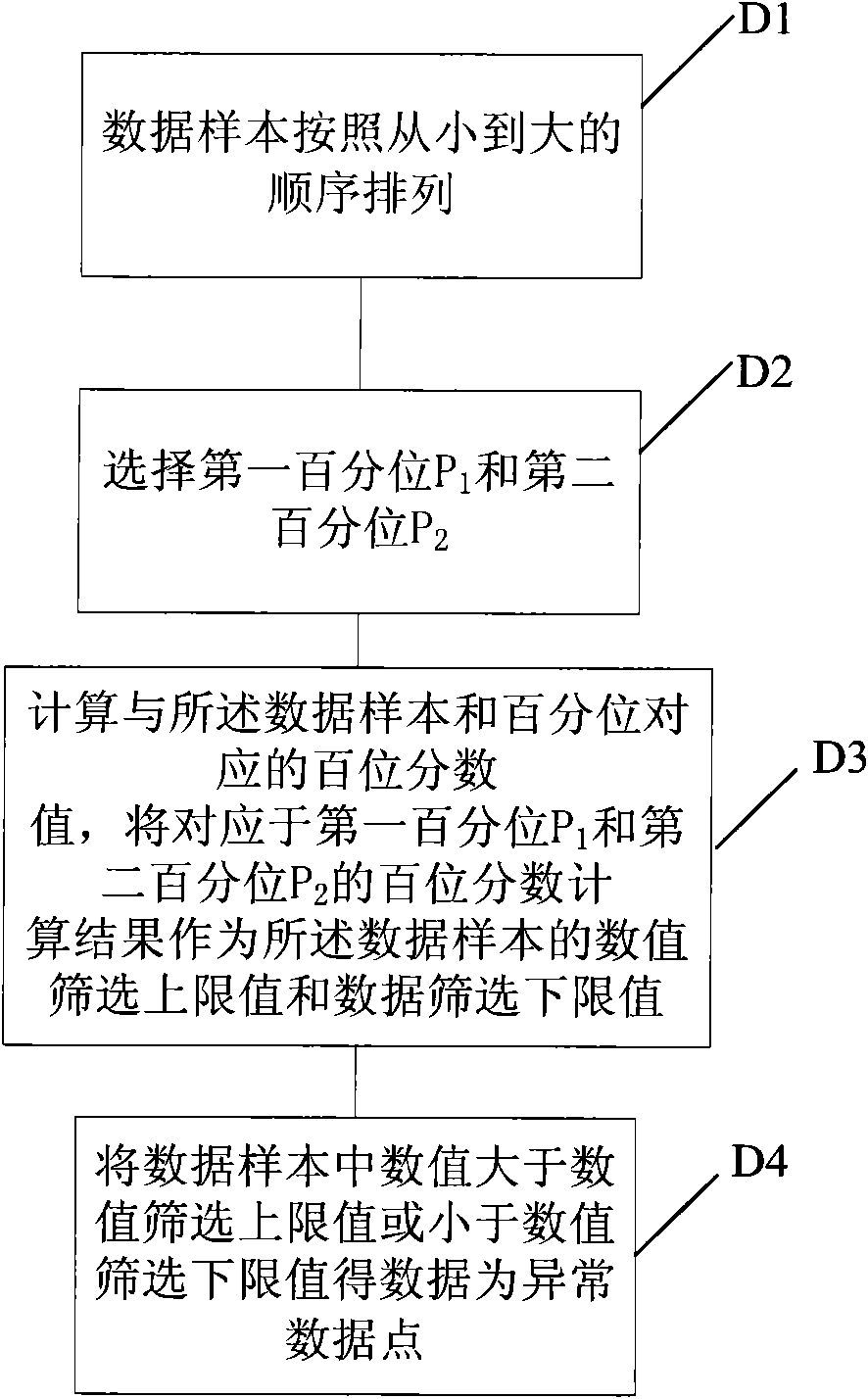

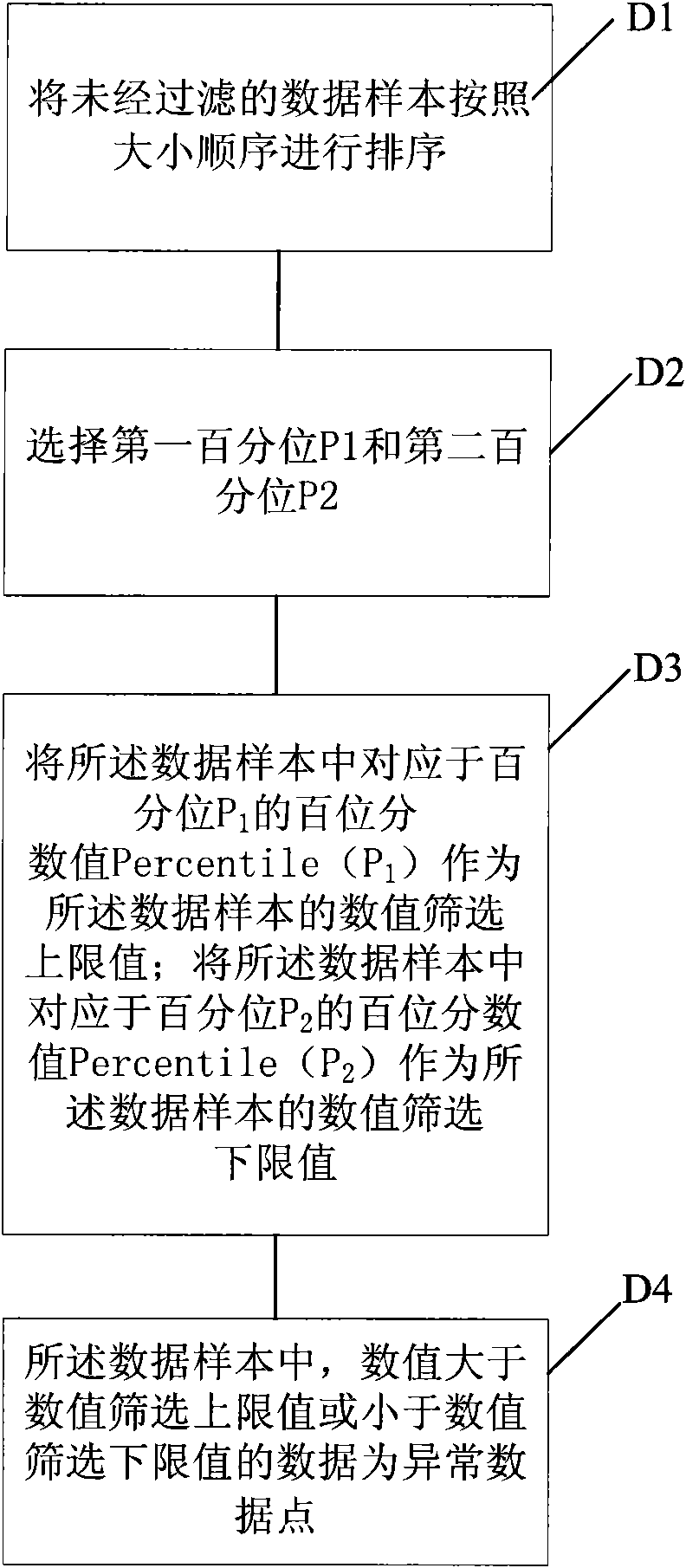

[0048] refer to Figure 5 , an embodiment of the statistical process control device of the present invention, comprising:

[0049] The data sample sorting unit M1 is used to sort the unfiltered data samples in order of size;

[0050] Percentile selection unit M2 for selecting the first percentile P 1 and the second percentile P 2 ;

[0051] The data screening limit calculation unit M3 is used to calculate the percentile value corresponding to said data sample and percentile, which will correspond to the first percentile P 1 and the second percentile P 2 The calculation result of the percentile of the above data sample is used as the numerical screening upper limit value and the data screening lower limit value;

[0052] A determining unit M4, configured to determine data in the data sample whose value is greater than the upper limit of numerical screening or less than the lower limit of numerical screening as abnormal data points.

[0053] In a specific implementation, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com