Intelligent opto-electrical direct reader

A photoelectric direct reading and photoelectric sensor technology, applied in the field of instruments and measuring instruments, can solve the problems of unintuitive production process, increased cost, increased volume, etc., and achieve the effect of improving anti-light interference performance and stabilizing communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention will be further described:

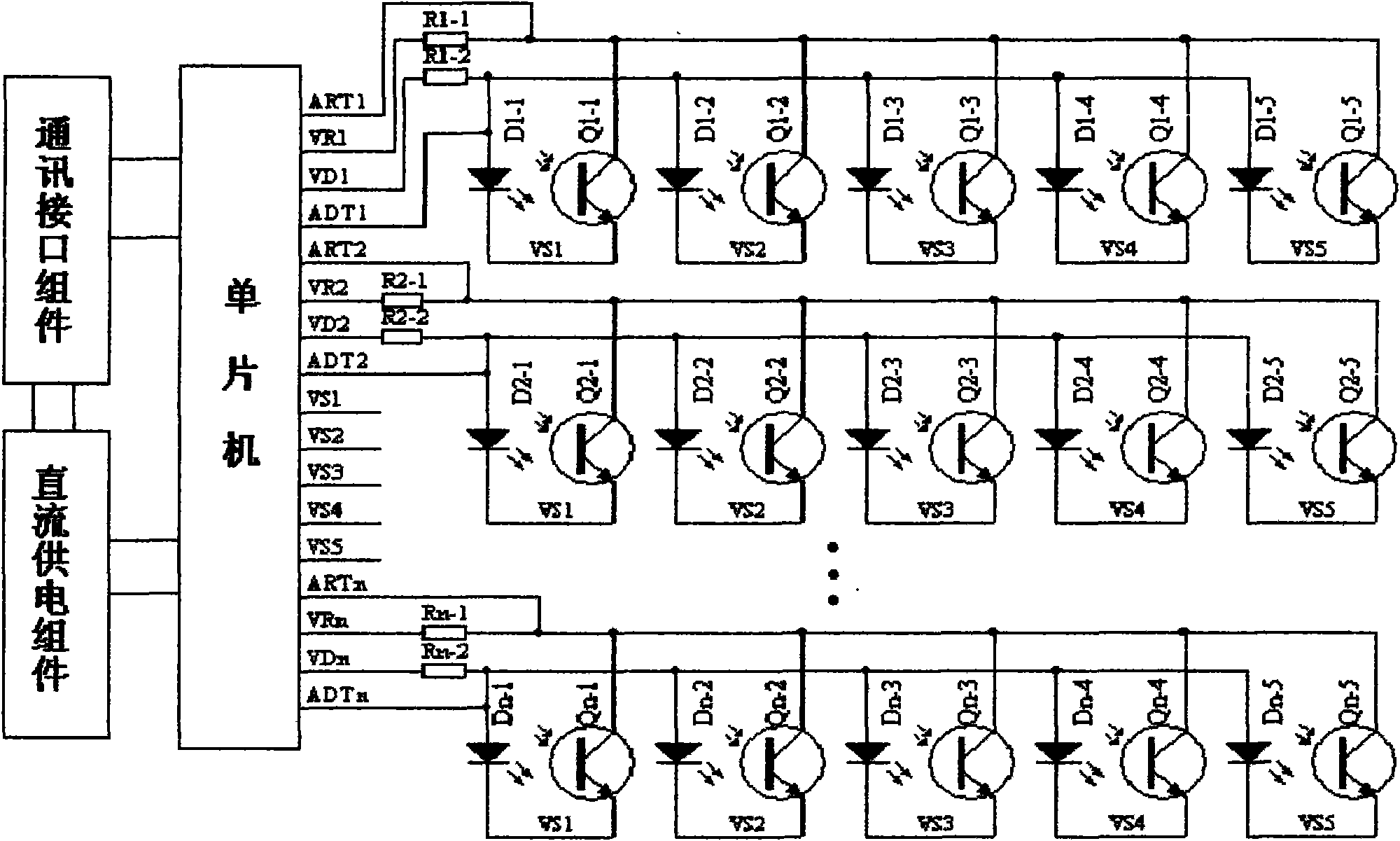

[0016] Such as figure 1 As shown: the intelligent photoelectric direct reader provided by this embodiment includes: a single-chip microcomputer, a communication interface assembly, a DC power supply assembly, and a plurality of groups of photoelectric sensors composed of multiple pairs of photosensitive receiving tubes and light emitting tubes. coder components, the figure 1 Among them, a photoelectric sensor composed of 5 pairs of photosensitive receiving tubes and a pair of light emitting tubes is used, and a photoelectric sensor decoder is composed of n groups of photoelectric sensors. The photoelectric sensor decoder provides a detailed electrical principle connection diagram. figure 1 Among them, Dn-m, and Qn-m (m represents the marked number of 1-5) form a pair of light emitting tubes, photosensitive receiving tubes, Dn-1, and Qn-1 to Dn-5, and Qn-5 A total of 5 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com