Grinding equipment

A technology of equipment and grinding discs, which is applied in the direction of grinding/polishing equipment, metal processing equipment, electrical components, etc., to achieve the effect of improving grinding yield, improving overall productivity, and reducing consumption area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

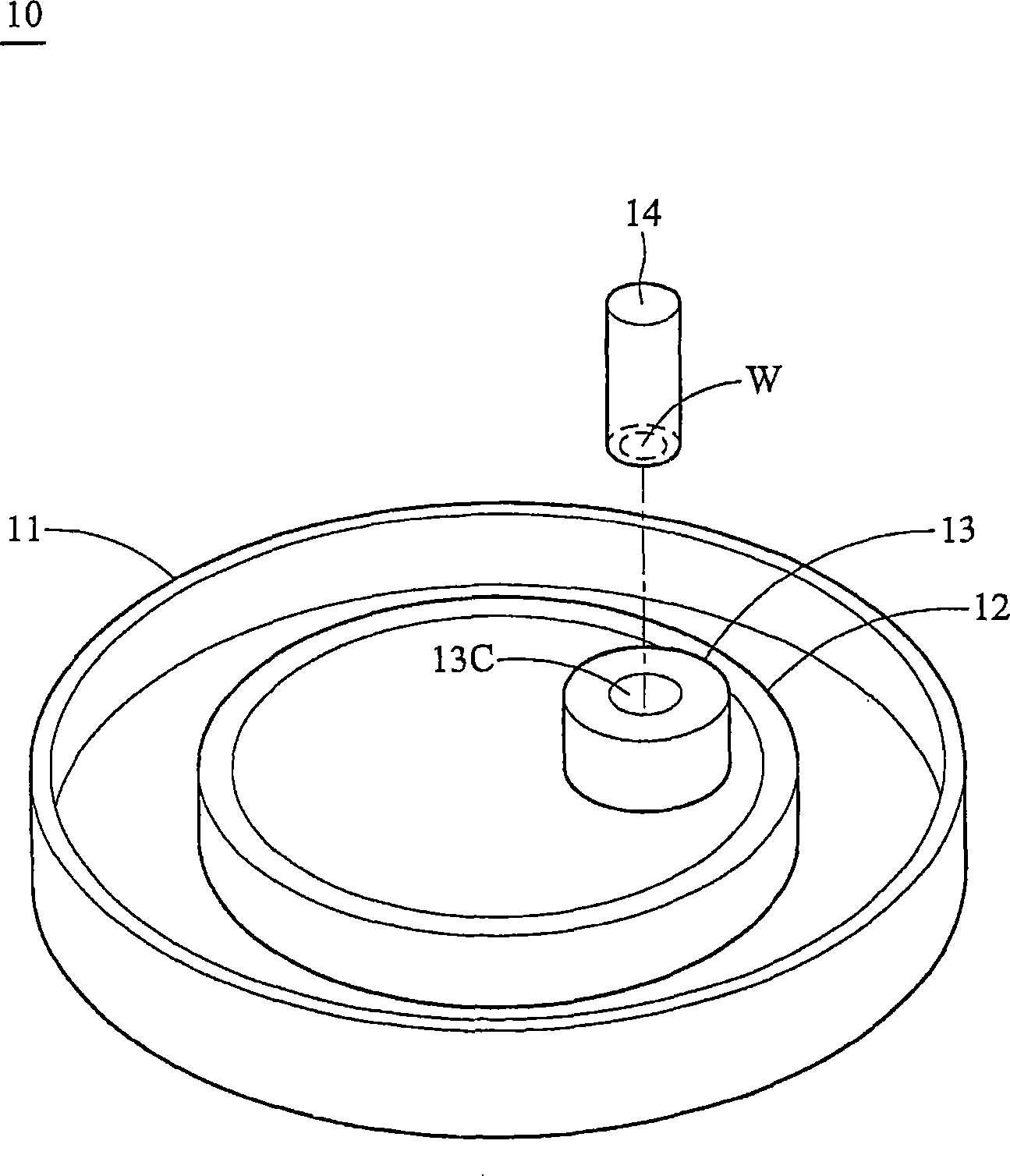

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

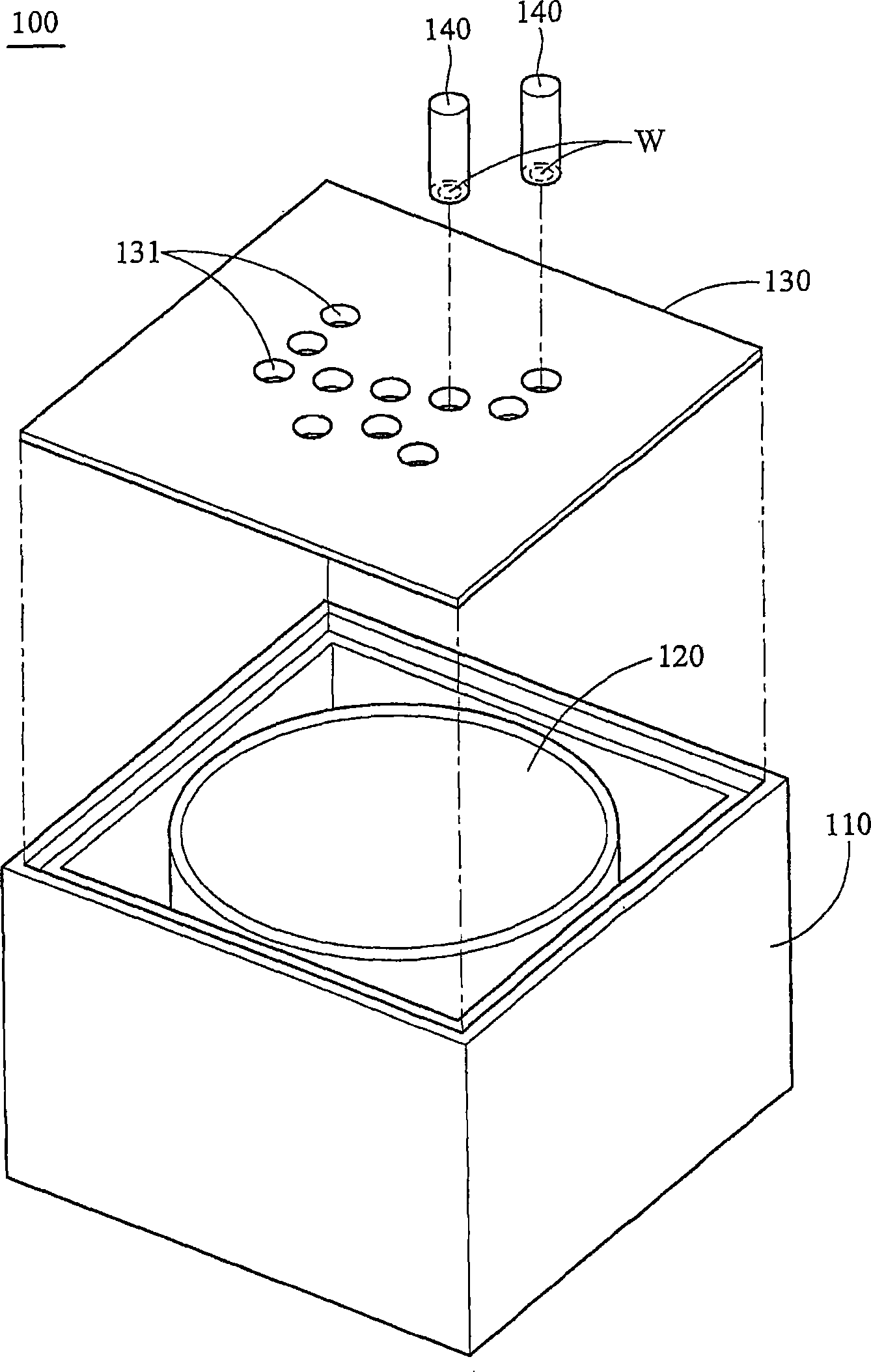

[0027] It should be noted that in this embodiment, the auxiliary jig 130 is mounted on the edge of the opening of the main body 110 , but it is not limited thereto, as long as the auxiliary jig 130 can be fixed above the grinding disc 120 .

[0028] When grinding the wafer W, the operator puts the end face of the shaft 140 down into one of the holes 131 so that the end face of the shaft 140 is opposite to the grinding disc 120, and the wafer W is brought into contact with the rotating grinding disc 120 to Wafer W is ground.

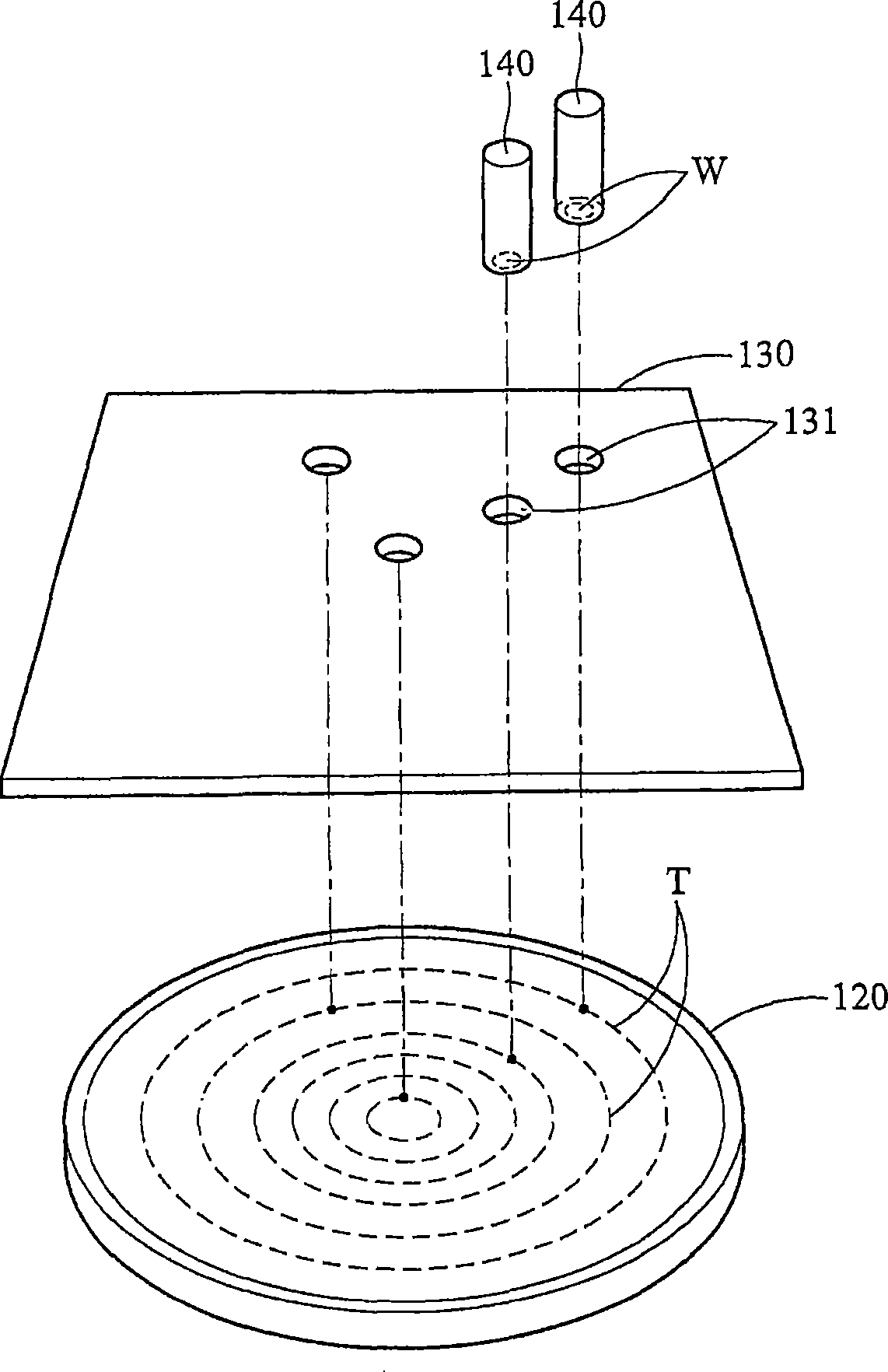

[0029] Cooperate see image 3 , the grinding disc 120 has a plurality of tracks T, and the position of each hole 131 is set relative to each non-repeating track T, so that each wafer W can be ground on a different track T. Also because of this, there is no limit on the number of the axis 140 and the hole 131 , it only needs to be determined that each wafer W can be ground on different tracks T.

[0030] The diameter of the hole 131 is slightly larger th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com