Precast concrete slab and preparation method thereof

A prefabricated concrete slab and concrete technology, applied in the direction of floor slabs, manufacturing tools, building components, etc., can solve the problems of falling off of joints, sliding, and inconsistency between prefabricated concrete parts and cast-in-place parts, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

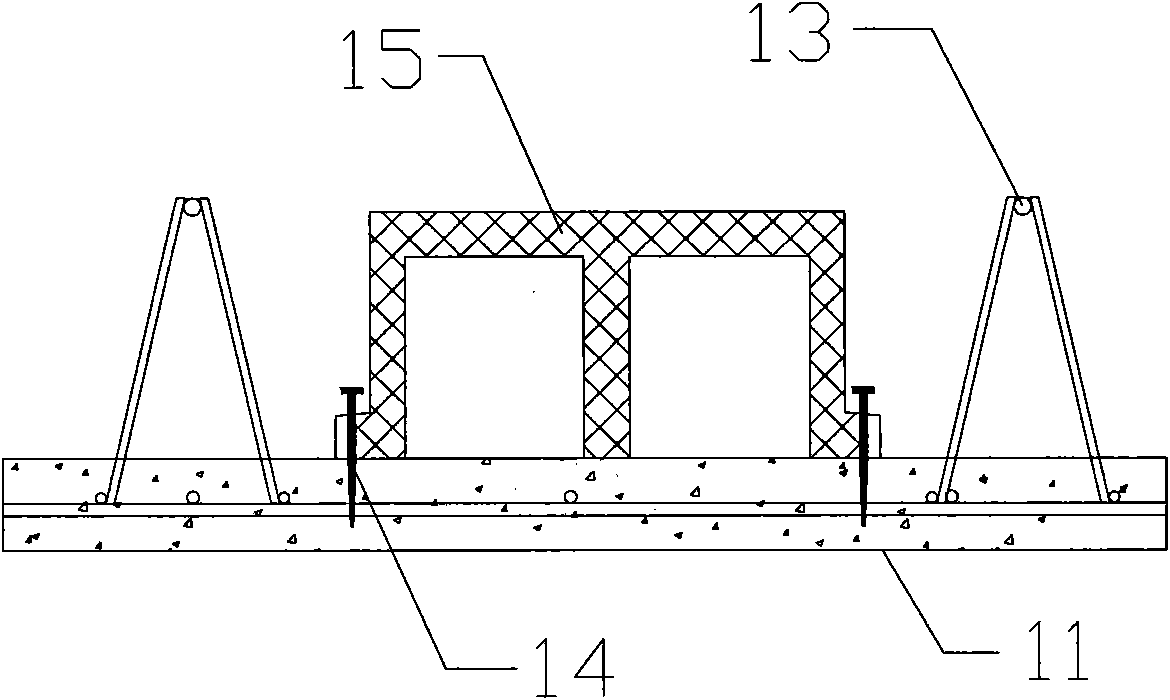

[0024] Such as figure 1 Shown is the structural representation of the embodiment of the prefabricated concrete slab of the present invention. The prefabricated concrete slab includes a plate-shaped main body 11 composed of steel bars and concrete wrapping the steel bars. The lower surface of the plate-shaped main body 11 is a smooth plane, while its upper surface includes a superimposed structure layer 12 integrated with the plate-shaped main body. and / or punch marks.

[0025] On the above-mentioned superimposed structural layer 12, the comb marks, indentations and / or punch marks account for 30%-80% of the surface area of the entire superimposed structural layer. These comb marks, indentations and / or punch marks can be grooves or pits. The above-mentioned comb marks and indentations can be swept out with a special bamboo broom or a special comb after the initial setting of the concrete surface, or dragged out with the ends of steel bars and wooden sticks, and the punch ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com