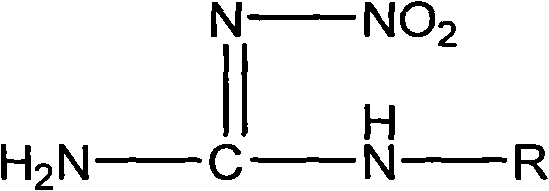

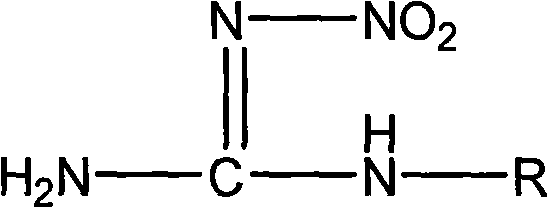

Methyl nitroguanidine and preparation method thereof

A technology of methyl nitroguanidine and nitroguanidine, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of reducing the yield of methyl nitroguanidine products, complex production process, etc., and achieves Low pollution, high reaction yield and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

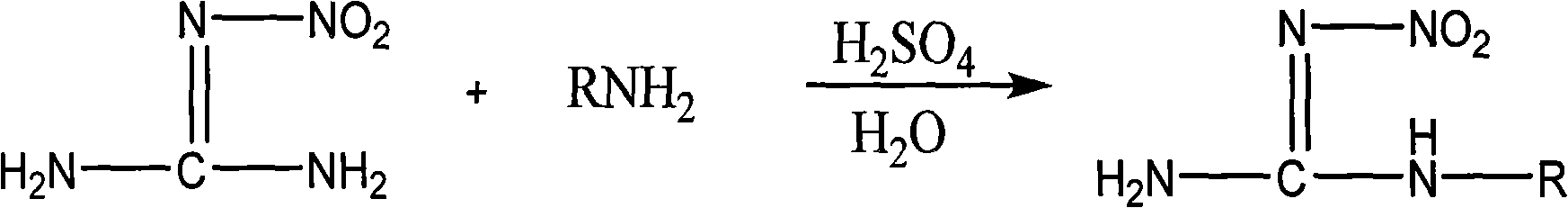

Method used

Image

Examples

Embodiment 1

[0016] According to the molar ratio of reactant nitroguanidine, methylamine, water, sulfuric acid is: nitroguanidine: methylamine: water: sulfuric acid=1: 2: 10: 0.1.

[0017] Put a certain concentration of 800kg dilute sulfuric acid solution into a 1500L reaction kettle from the head tank, add alkylamine solution, adjust the pH value to 8.5, then put in 600kg of wet nitroguanidine, raise the temperature to 100°C, and add the remaining alkylamine solution, adjust the pH value at 10, and control the temperature at 70°C for about 5 hours. After the reaction, the temperature was lowered to 5° C., centrifugal dehydration was performed, and the filter cake was washed with cold water to obtain about 600 kg of crude methyl nitroguanidine.

[0018] Put the above-mentioned crude methyl nitroguanidine into a 1500L kettle with 800L of water, raise the temperature to 90°C, wait for the methylnitroguanidine to completely dissolve and filter, then cool the filtrate to 5°C in the crystalliza...

Embodiment 2

[0020] According to the mol ratio of reactant nitroguanidine, methylamine, water, sulfuric acid is: nitroguanidine: methylamine: water: sulfuric acid=1: 4: 15: 0.15.

[0021] Put a certain concentration of 800kg dilute sulfuric acid solution into a 1500L reactor from the head tank, add the alkylamine solution, adjust the pH value to 9.0, then put in 600kg of wet nitroguanidine, raise the temperature to 105°C, and add the remaining alkylamine solution, adjust the pH value at 11, and control the temperature at 75°C for 6 hours. After the reaction, the temperature was lowered to 5° C., centrifugal dehydration was performed, and the filter cake was washed with cold water to obtain about 600 kg of crude methyl nitroguanidine.

[0022] Put the above-mentioned crude methyl nitroguanidine into a 1500L kettle with 800L of water, raise the temperature to 90°C, wait for the methylnitroguanidine to completely dissolve and filter, then cool the filtrate to 5°C in the crystallization kettle...

Embodiment 3

[0024] According to the molar ratio of reactant nitroguanidine, methylamine, water, sulfuric acid is: nitroguanidine: methylamine: water: sulfuric acid=1: 6: 20: 0.25.

[0025] Put 800kg of dilute sulfuric acid solution of a certain concentration into a 1500L reaction kettle from the head tank, add alkylamine solution, adjust the pH value to 8.5, then put in 600kg of wet nitroguanidine, raise the temperature to 105°C, and add the remaining alkylamine solution, adjust the pH value at 10, and control the temperature at 80°C for 5 hours. After the reaction, the temperature was lowered to 5° C., centrifugal dehydration was performed, and the filter cake was washed with cold water to obtain about 600 kg of crude methyl nitroguanidine.

[0026] Put the above-mentioned crude methyl nitroguanidine into a 1500L kettle with 800L of water, raise the temperature to 90°C, wait for the methylnitroguanidine to completely dissolve and filter, then cool the filtrate to 5°C in the crystallizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com