Catalyst for oxidizing-synthesizing glutaric dialdehyde with cyclopentene and preparation method thereof

A technology for synthesizing glutaraldehyde and a catalyst, applied in the chemical industry, can solve the problems of expensive copolymer template agent, high catalyst cost, air pollution and the like, and achieves the effects of good industrial application prospect, low catalyst cost and sufficient sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

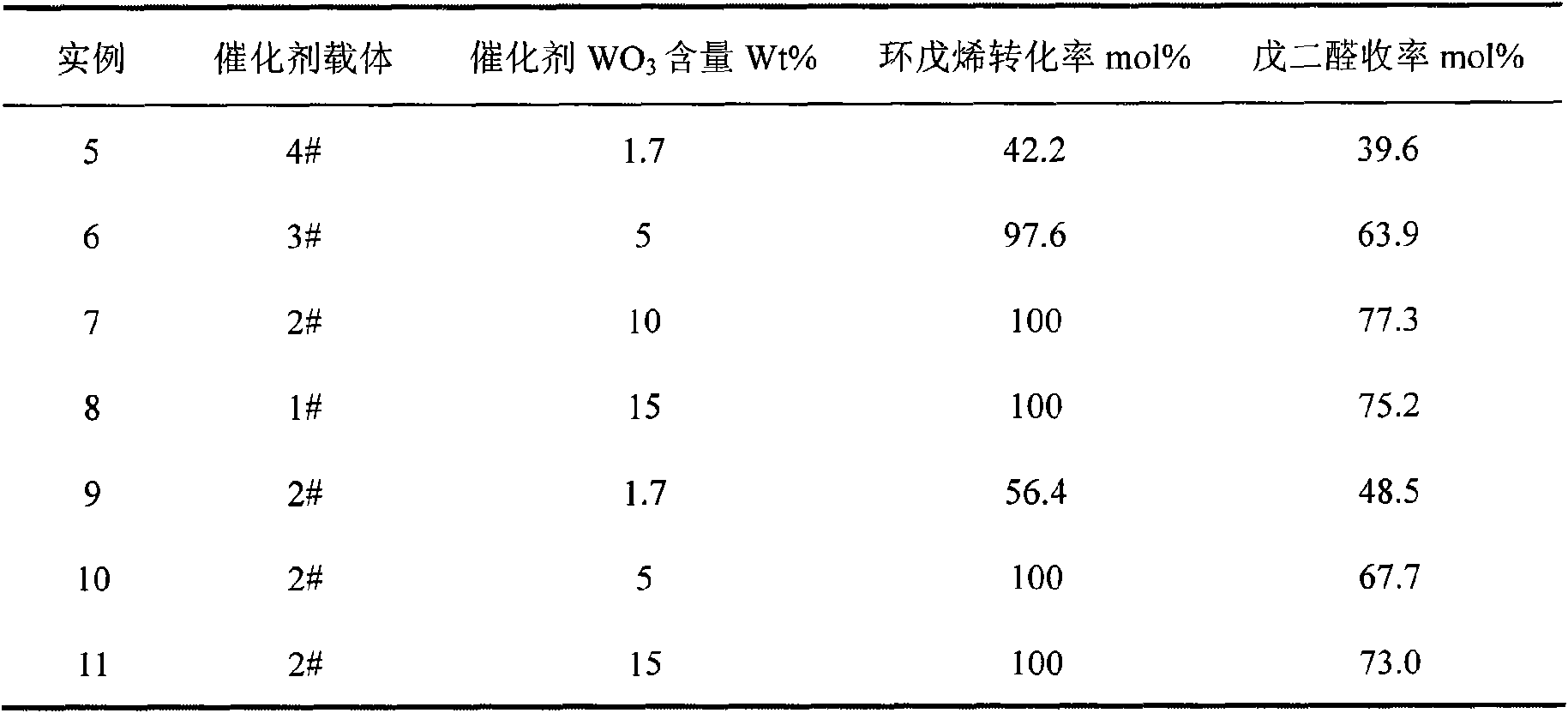

Examples

Embodiment 1

[0024] According to the molar ratio of tetraethyl silicate: tetrabutyl titanate: octadecyl polyoxyethylene ether: ethanol: isopropanol: water = 1: 0.01: 0.025: 9: 150, the first template octadecane Base polyoxyethylene ether is dissolved in water-ethanol mixed solution, tetrabutyl titanate is dissolved in isopropanol, and then tetraethyl silicate and tetrabutyl titanate in isopropanol are mixed and slowly added dropwise to Template agent-water-ethanol mixture (in a state of strong stirring), heated to 50°C and stirred for 24 hours, filtered, washed with water and ethanol three times successively, dried the obtained filter cake in an oven at 110°C for 5 hours, and then Calcined at 550° C. for 4 hours in a muffle furnace, then ground and sieved to obtain a Ti-MSU mesoporous molecular sieve with a particle size of 80-100 mesh. The BET specific surface area measured by low temperature nitrogen adsorption-desorption method is 980m 2 / g, the average pore diameter is 3.8nm, and the ...

Embodiment 2

[0026] According to Example 1, the templating agent was changed to hexadecyl polyoxyethylene ether, and the molar ratio of raw materials was changed to tetraethyl silicate: tetrabutyl titanate: hexadecyl polyoxyethylene ether: ethanol: isopropyl Alcohol: water = 1: 0.015: 0.025: 9: 150, and the remaining steps are the same as in Example 1. The obtained Ti-MSU mesoporous molecular sieve molecular sieve specific surface area is 1030m 2 / g, the average pore diameter is 4.2nm, and the silicon / titanium molar ratio is 1:0.015, which is recorded as carrier 2#.

Embodiment 3

[0028] According to Example 2, the molar ratio of raw materials was changed to tetraethyl silicate: tetrabutyl titanate: hexadecyl polyoxyethylene ether: ethanol: isopropanol: water = 1: 0.025: 0.025: 9: 150 , the rest of the steps are the same as in Example 2. The obtained Ti-MSU mesoporous molecular sieve molecular sieve has a specific surface area of 940m 2 / g, the average pore diameter is 4.0nm, and the silicon / titanium molar ratio is 1:0.024, which is recorded as carrier 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com