An induction heating cooking device

A technology of induction heating and cooker, which is applied in the direction of induction heating, induction heating control, induction heating device, etc., can solve the problems of affecting the accuracy of temperature measurement, the decline of the mechanical strength of the top plate, and the inconvenient use of the cooker, so as to reduce infrared radiation and stabilize The effect of ambient temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

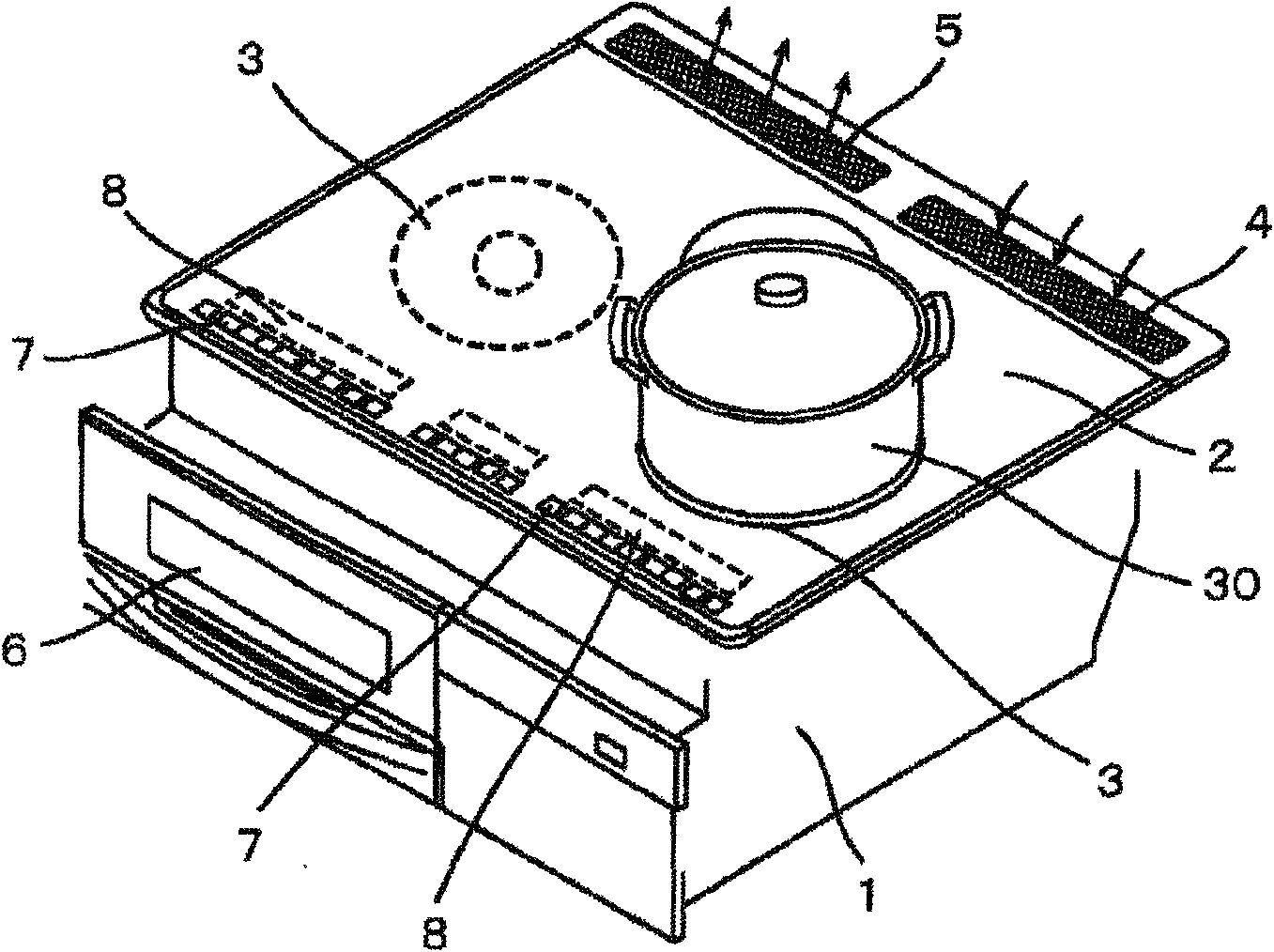

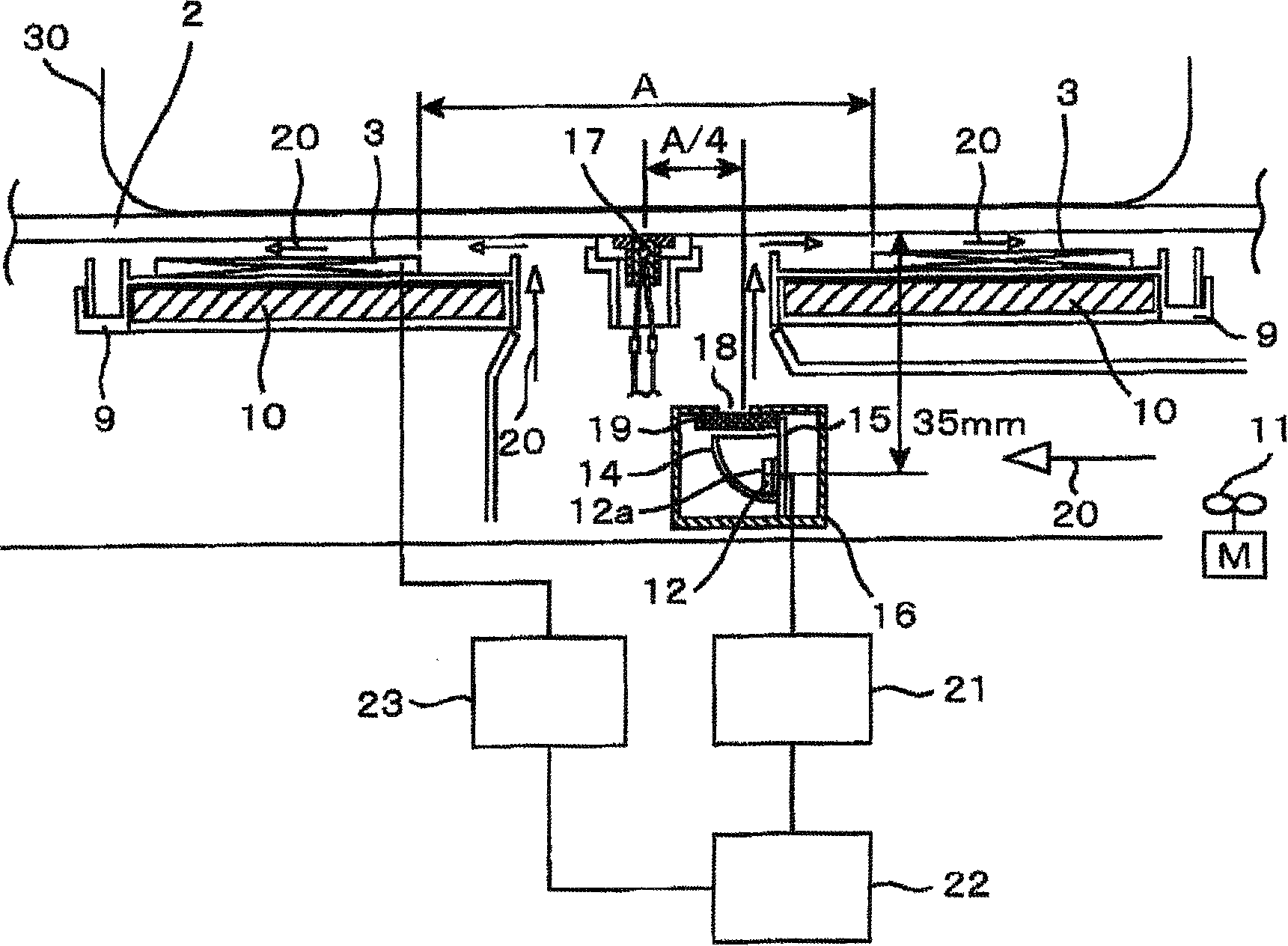

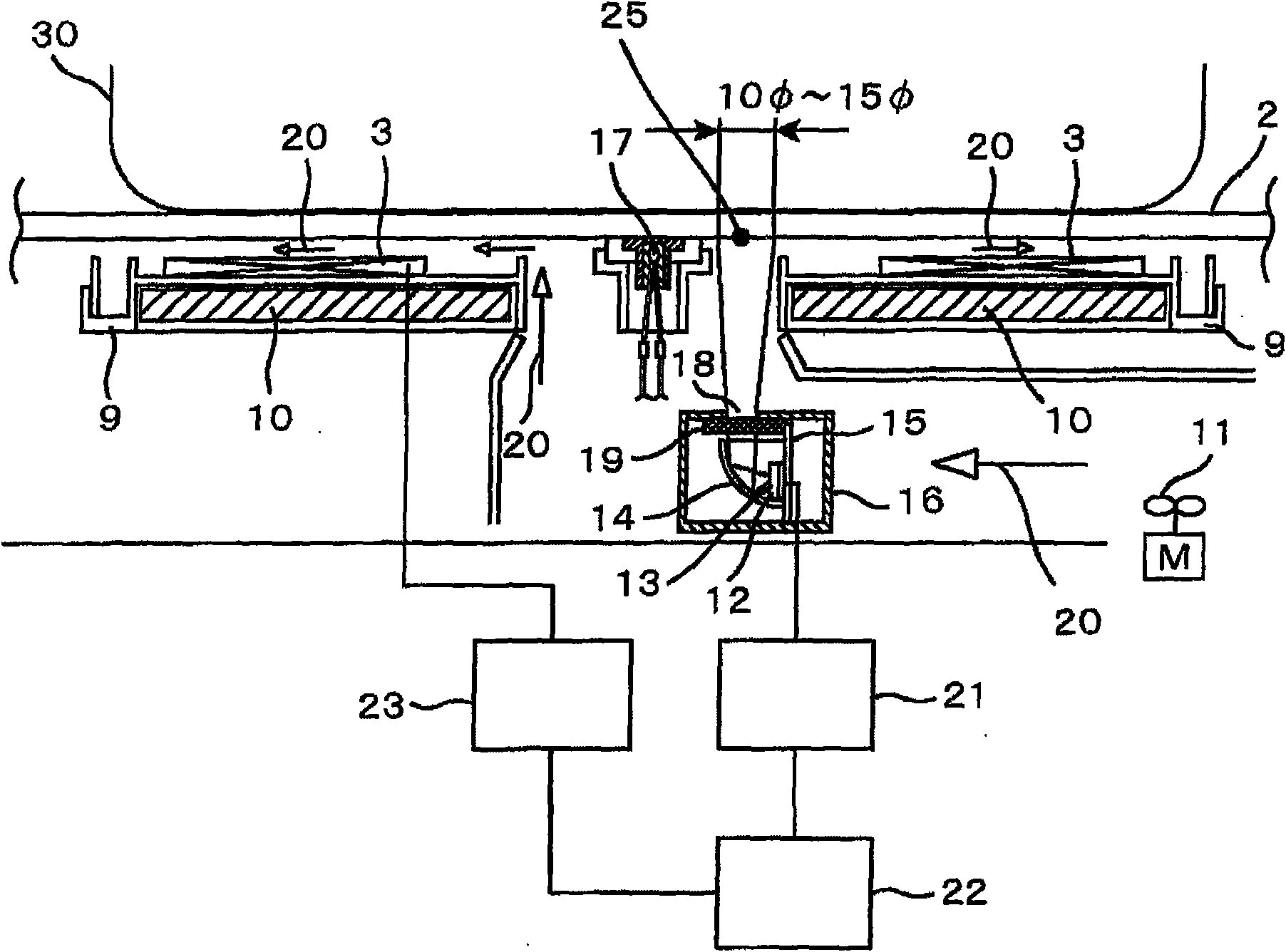

[0039] figure 1 is an external perspective view of the induction heating cooker in the first embodiment, figure 2 and image 3 is a longitudinal sectional view of main parts of the induction heating cooker in the first embodiment, Figure 4 is a graph representing the spectral radiation intensity curve of a blackbody, Figure 5 It is a graph showing the transmittance curve of crystal glass.

[0040] exist figure 1 Among them, the top plate 2 is horizontally arranged on the upper surface of the main body 1 of the induction heating cooker.

[0041] The top plate 2 is made of highly heat-resistant crystal glass, and an object to be heated, such as a pan 30 made of a magnetic material such as iron or a non-magnetic material such as aluminum, is placed.

[0042] Heating coils 3 are arranged on the left and right in the upper part of the main body 1 below the top plate 2 . An object to be heated such as a pan 30 placed on the top plate 2 is induction heated.

[0043] On the ...

Embodiment 2

[0086] Image 6 It is a longitudinal sectional view of main parts showing a second embodiment of the present invention.

[0087] exist Image 6 In , the same parts as those in the above-mentioned first embodiment are assigned the same symbols, and description thereof will be omitted.

[0088] In this embodiment, a wall 24 made of resin or the like having a small heat capacity and poor thermal conductivity is provided between the shield case 16 and the infrared sensor 12 .

[0089]As described above, by arranging the infrared sensor 12 in the space covered by the wall 24, even if the temperature of the shield case 16 occurs due to the influence of the leakage magnetic flux from the heating coil 3 or the influence of the temperature rise of the top plate 2 and the heating coil 3 Changes, the influence of temperature is also difficult to transfer to the infrared sensor 12,. Therefore, high-precision temperature detection can be performed.

[0090] In addition, by covering the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com