Resistance structure for improving silicon-on-insulator (SOI) circuit ESD protection network

A resistance structure and network technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of easy burnout of resistors, and achieve the effect of reducing room temperature resistance, overcoming easy burnout, and improving ESD resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

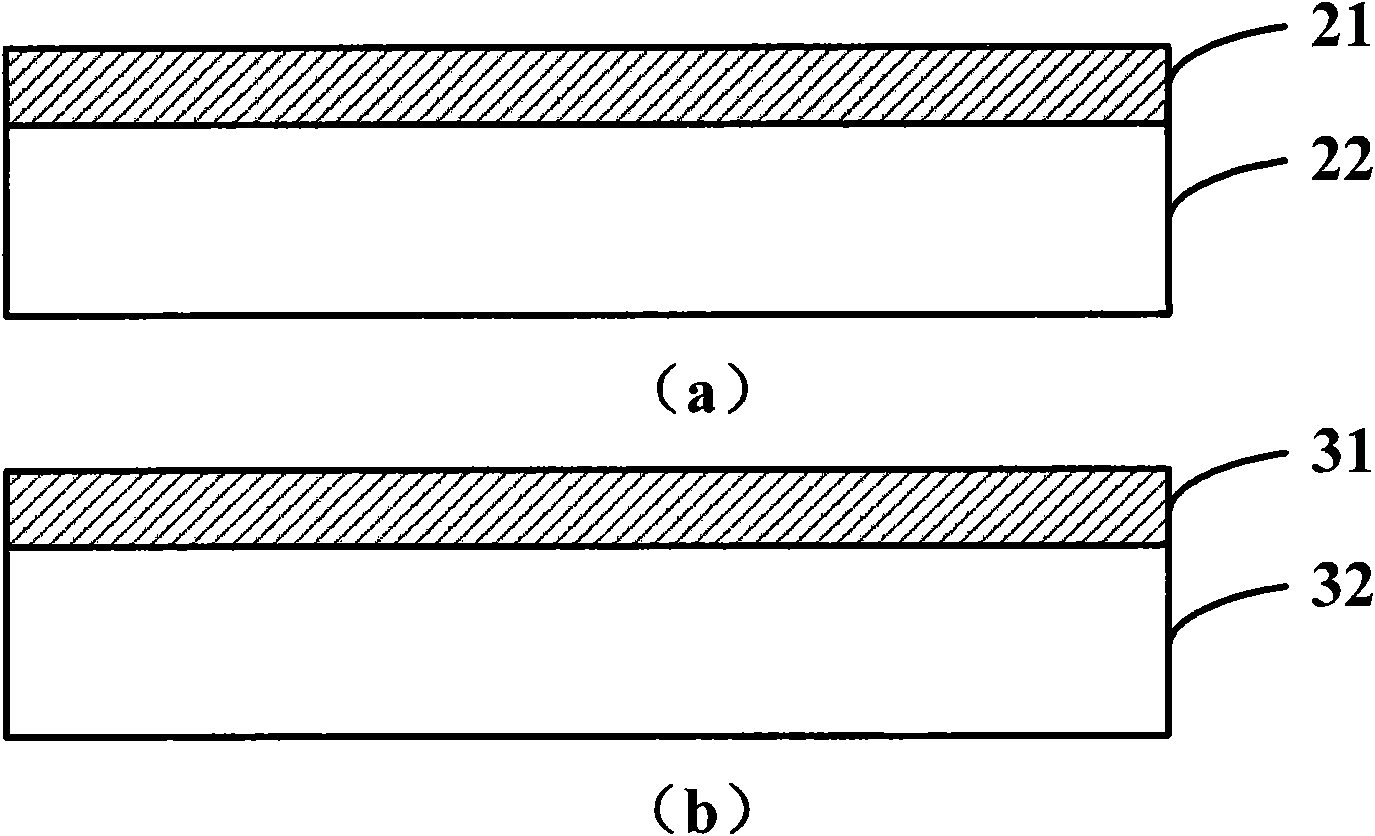

[0027] Such as figure 1 As shown, the present invention uses silicon 22 or silicides 21 and 31 on polysilicon 32 as a resistive and conductive thin film, which is a resistive structure for ESD protection network. The silicon 22 or polysilicon 32 can be any doped SOI silicon film or polysilicon film whose sheet resistance is more than 5 times larger than that of the corresponding silicides 21 and 31 . The silicides 21 and 31 refer to a compound formed by a physical-chemical reaction between metal and silicon, which has a conductivity between metal and semiconductor, mainly including titanium silicide, cobalt silicide or nickel silicide.

[0028] In this resistance structure, the silicide film plays the main role of conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com