Working method of strap-down magnetic inertia combination system

A combination system and working method technology, applied in the field of navigation technology measurement, can solve the problems of sacrificing rudder resources, system complexity, increasing invalid weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

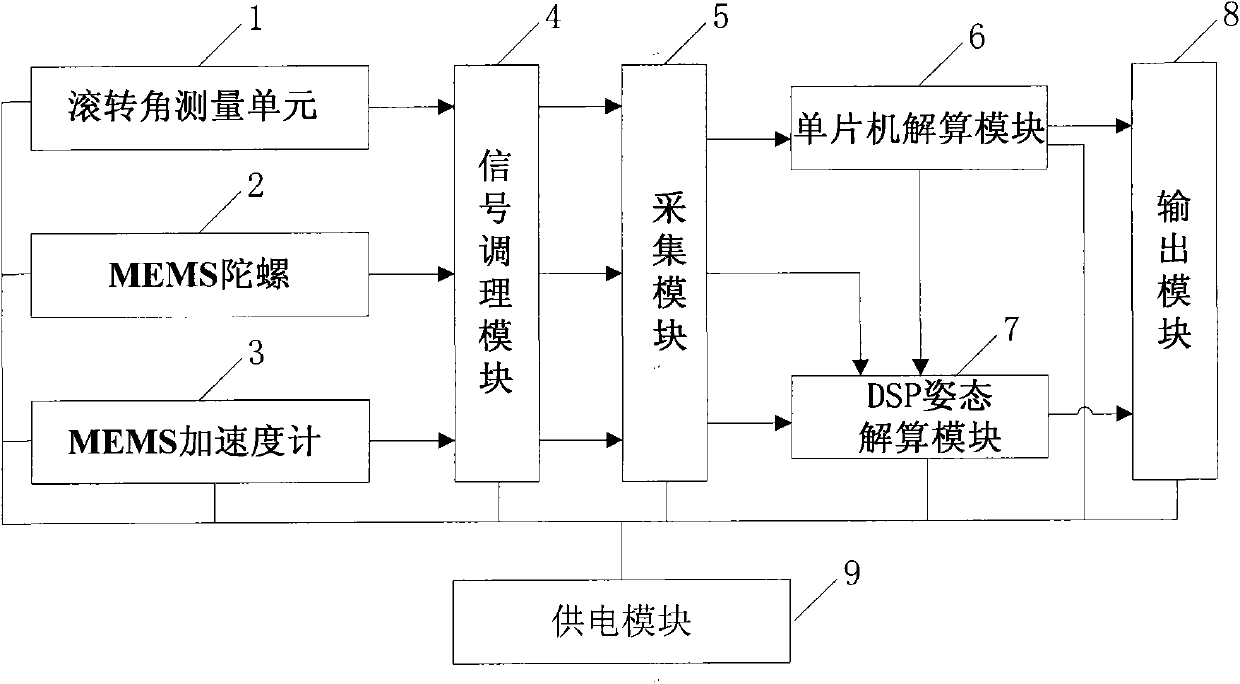

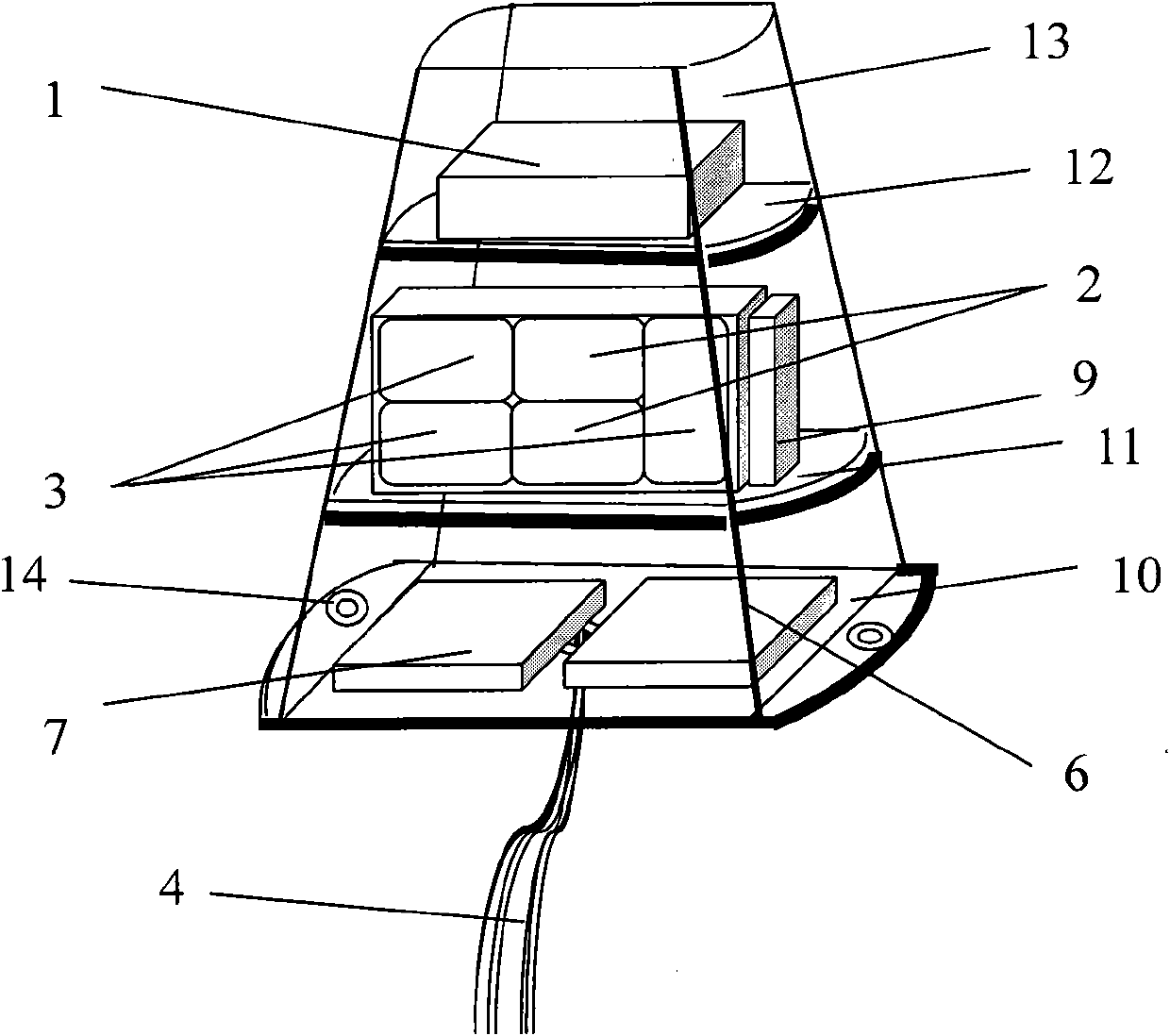

[0092] The magnetic-inertial combination system of the present invention is implemented according to the following technical scheme: it mainly consists of two uniaxial angular rate micro-machined gyroscopes, three micro-machined accelerometers, a two-axis geomagnetic roll angle measurement unit, a missile-borne computer and a power supply circuit It is directly fixed on the structural body in a strapdown manner. All components and MEMS sensors use solid chips, which are mounted on the board level through damping sheets in layers, and are potted in the housing with damping glue to form a whole. Workflow: Binding the shooting direction of the rotating projectile, the local magnetic inclination angle, and the magnetic declination angle. With the rotation of the projectile body, the geomagnetic roll angle measurement unit obtains the magnetic signal of the sinusoidal change, and then calculates the magnetic signal according to the sinusoidal change. The roll angle and roll rate of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com