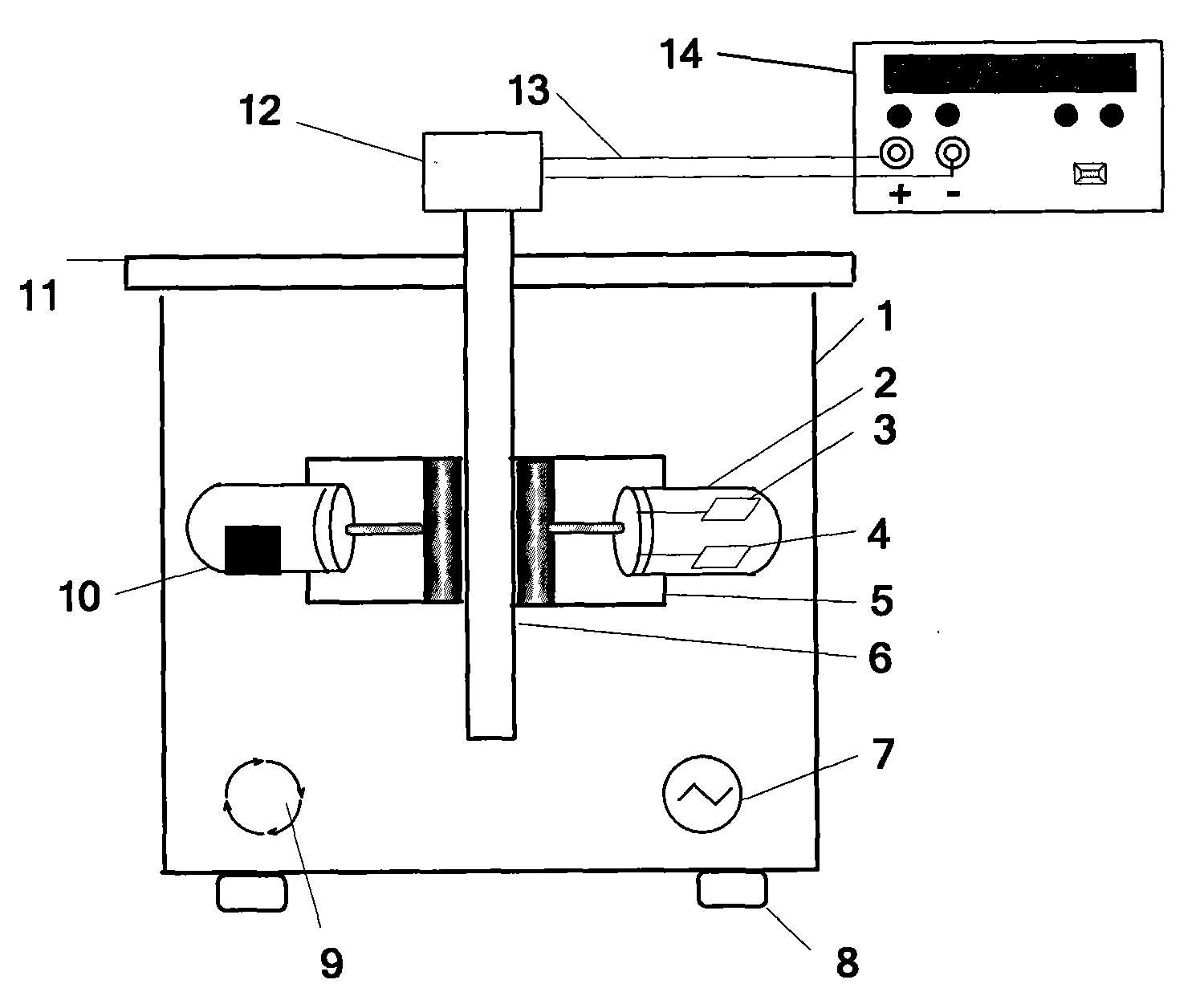

Method and device for preparing copper powder by intensified electrolysis

A technology of electrolytic copper powder and copper powder, applied in the direction of electrolytic components, electrolytic process, cells, etc., can solve the problems of low current efficiency, increase of electrolytic cell voltage, power consumption, etc., to reduce production cost, improve economic value, and increase current efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

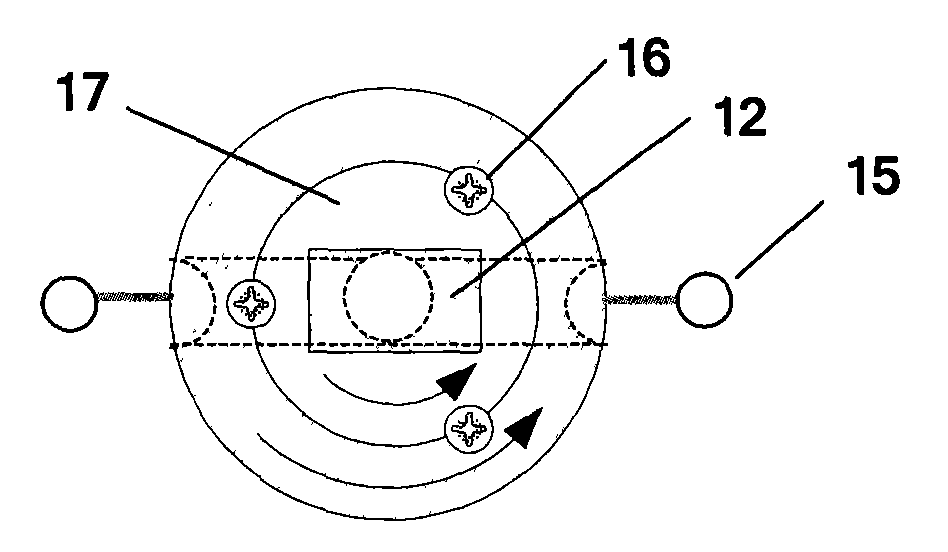

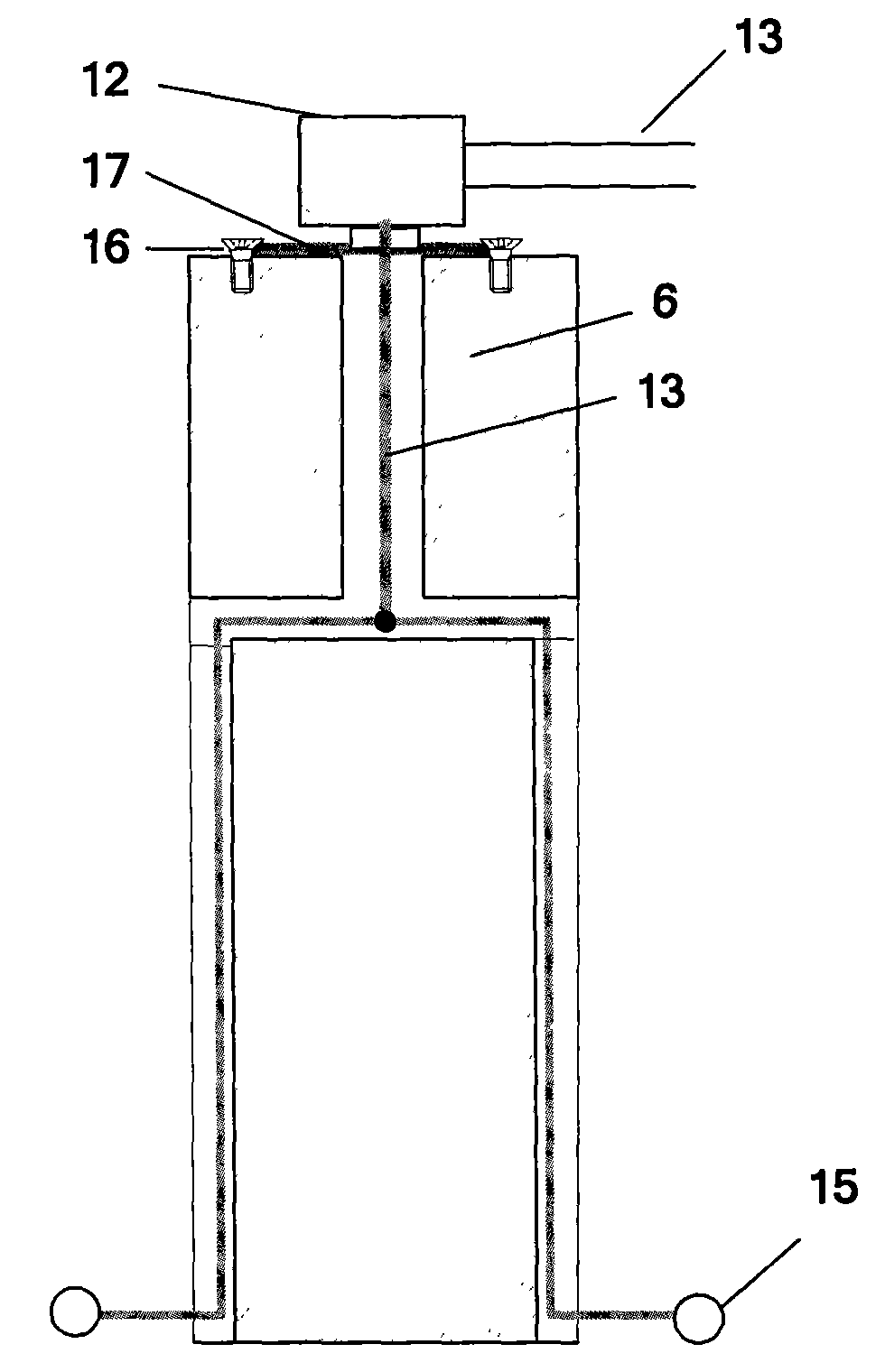

Method used

Image

Examples

Embodiment 1

[0023] Prepare an electrolyte with a copper sulfate concentration of 10g / l, a sulfuric acid concentration of 9.8g / l, and a sodium dodecylbenzenesulfonate concentration of 1.5g / l, using a copper plate as the anode, a nickel sheet as the cathode, and a current density of 2000A / m 2 , Under the condition of normal gravity (gravity coefficient is 1), the electrolysis of copper powder is carried out, and the electrolysis time is 75min. After the electrolysis, the copper powder is collected, washed with water, anti-oxidation treatment, washed with water, and dried in sequence. The average particle size of the obtained copper powder is 20.1 μm, and the electrolytic current efficiency is 55.7%.

Embodiment 2

[0025] Prepare an electrolyte with a copper sulfate concentration of 10g / l, a sulfuric acid concentration of 9.8g / l, and a sodium dodecylbenzenesulfonate concentration of 1.5g / l, using a copper plate as the anode, a nickel sheet as the cathode, and a current density of 2000A / m 2 , Under the condition that the gravity coefficient is 101, the copper powder is electrolyzed, and the electrolysis time is 75min. After the electrolysis, the copper powder is collected, washed with water, anti-oxidation treatment, washed with water, and dried in sequence. The average particle size of the obtained copper powder is 19.2 μm, and the electrolytic current efficiency is 74.2%.

Embodiment 3

[0027] Prepare an electrolyte with a copper sulfate concentration of 10g / l, a sulfuric acid concentration of 9.8g / l, and a sodium dodecylbenzenesulfonate concentration of 1.5g / l, using a copper plate as the anode, a nickel sheet as the cathode, and a current density of 4000A / m 2 , Under the condition that the gravity coefficient is 101, the copper powder is electrolyzed, and the electrolysis time is 75min. After the electrolysis, the copper powder is collected, washed with water, anti-oxidation treatment, washed with water, and dried in sequence. The average particle size of the obtained copper powder is 14.4 μm, and the electrolytic current efficiency is 68.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com