Method for producing high-grade paper tube with seamless surface

A production method and technology of paper tubes, applied in the direction of paperboard winding articles, etc., can solve the problems that it is difficult to meet the requirements of thin or ultra-thin material coiling, the surface of paper tubes is not smooth enough, and the accuracy of geometric dimensions is low, so as to achieve seamless surface , Good moisture-proof effect, precise size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

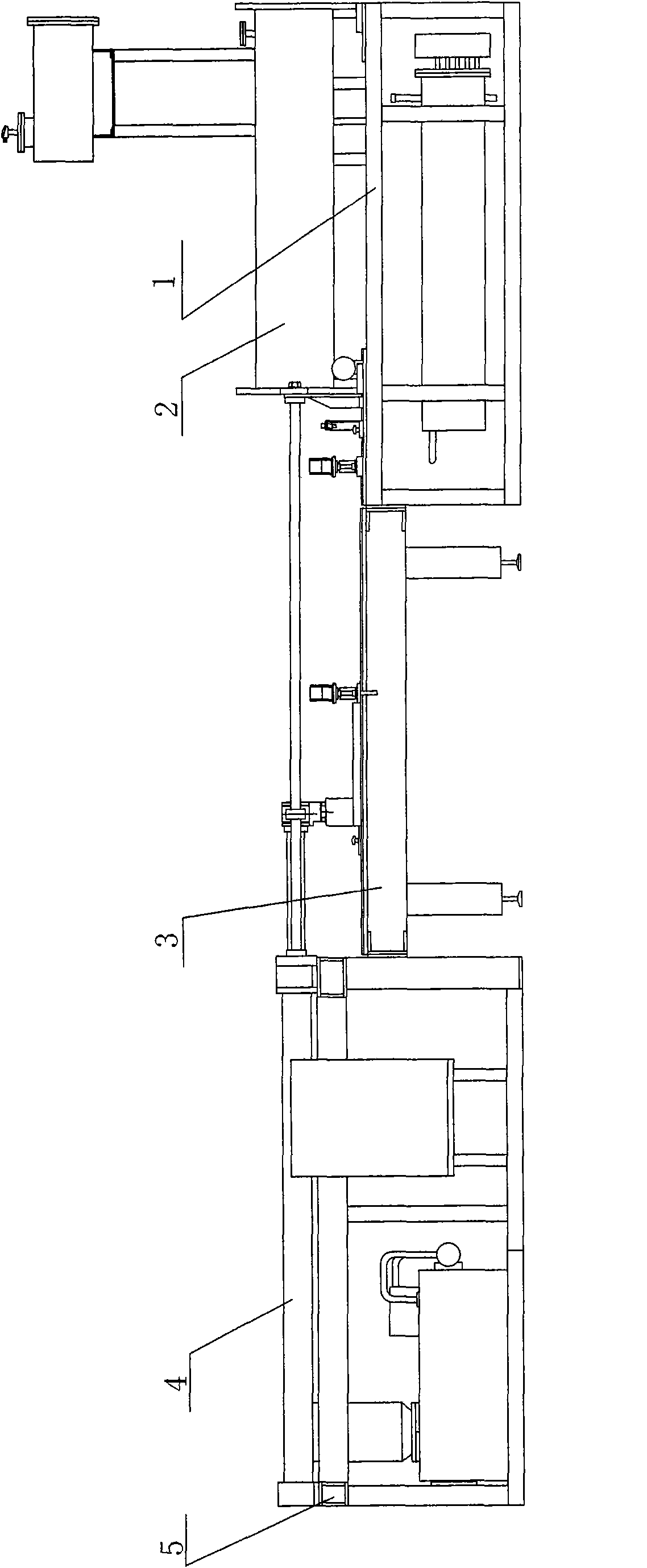

Image

Examples

Embodiment 1

[0033] The production method of the present invention mainly includes several processes such as raw material paper cutting, groove treatment, paper tape gluing, tube rolling, surface coating, rough cutting, paper tube drying, extrusion molding, and fine cutting. After the process, a layer of resin is coated on the outer surface of the wound paper tube. After the paper tube is roughly cut and dried, it is put into the inner extrusion molding machine one by one for extrusion molding. Because a layer of resin is coated on the outer surface of the paper tube Resin, under the action of internal extrusion molding, the resin is first melted into a film and then cooled, so that a seamless, smooth and clean resin layer is formed on the outer surface of the paper tube. The paper tube prepared by the method also has the characteristics of high straightness, high roundness, high surface hardness, etc., and overcomes all the defects existing in the original ordinary paper tube.

[0034] In...

Embodiment 2

[0048] The production method of the present invention mainly includes several processes such as raw material paper cutting, groove treatment, paper tape gluing, tube rolling, surface coating, rough cutting, paper tube drying, extrusion molding, and fine cutting. After the process, a layer of resin is coated on the outer surface of the wound paper tube. After the paper tube is roughly cut and dried, it is put into the inner extrusion molding machine one by one for extrusion molding. Because a layer of resin is coated on the outer surface of the paper tube Resin, under the action of internal extrusion molding, the resin is first melted into a film and then cooled, so that a seamless, smooth and clean resin layer is formed on the outer surface of the paper tube. The paper tube prepared by the method also has the characteristics of high straightness, high roundness, high surface hardness, etc., and overcomes all the defects existing in the original ordinary paper tube.

[0049] In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com