Acousto-optic Q-switched ytterbium-doped all-fiber laser

An acousto-optic modulator, all-fiber technology, applied in lasers, phonon exciters, laser parts, etc., can solve the problems of low coupling efficiency, complex experimental setup, and high misalignment sensitivity, achieve short rise and fall times, and improve coupling. The effect of high efficiency and diffraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

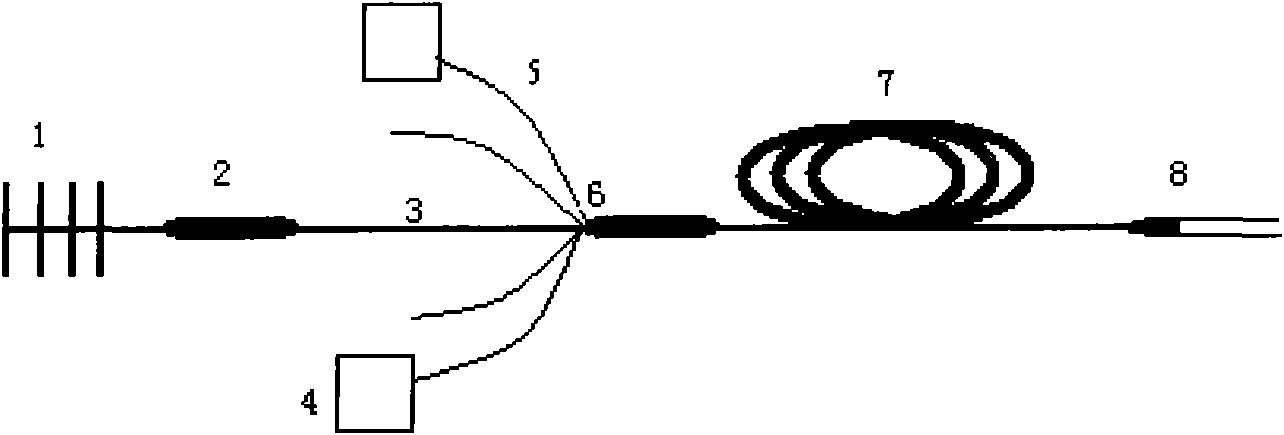

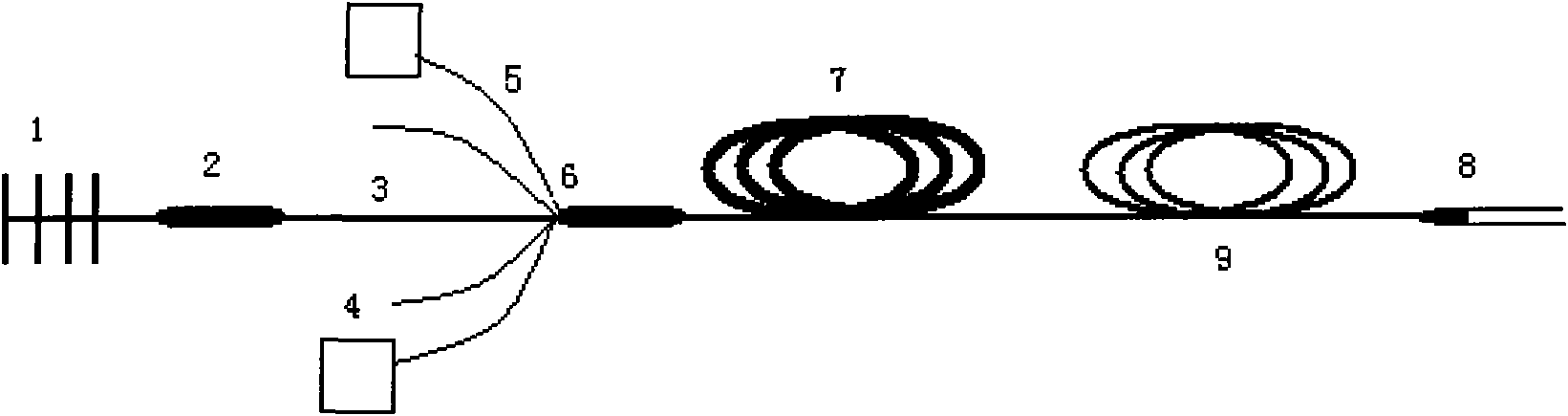

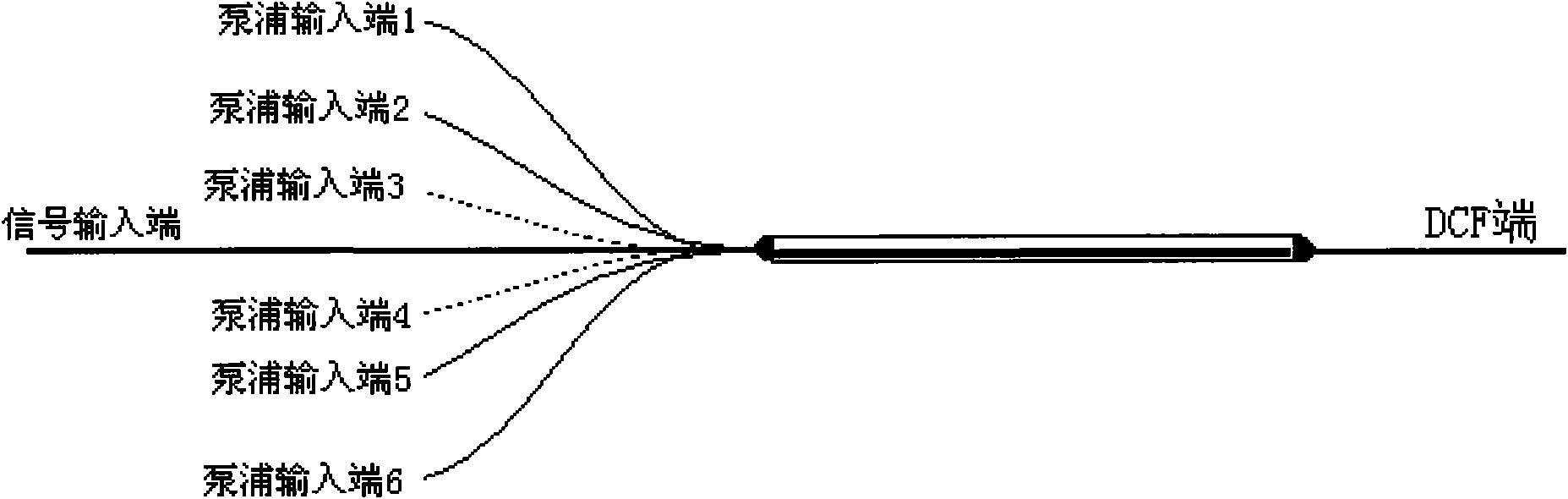

[0019] The structure of an acousto-optic Q-switched ytterbium-doped all-fiber laser is as follows figure 1 shown. It consists of: FBG fiber grating 1, acousto-optic modulator with pigtail AOM acousto-optic Q switch 2, multimode coupler 6, two laser diode LD pump sources 4, D-type double-clad ytterbium-doped fiber 7 and The laser output pigtail 8. Two LD semiconductor lasers 4 couple the pump light into the Yb-doped gain fiber 7 through the multimode coupler 6 to realize the pumping of the gain fiber 7 . FBG1 is connected to the signal terminal 3 of the multimode coupler through the AOM acousto-optic Q switch 2, and the end face of the FBG fiber grating 1 and the output pigtail 8 forms a resonant cavity. When an alternating voltage is applied to the acousto-optic modulator, The acousto-optic modulator periodically adjusts the loss in the resonant cavity to realize the pulse output of the all-fiber laser.

[0020] Q means the loss in the laser, and the acousto-optic Q switch ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com