Method for producing detonating fuse or detonator delay line with small diameter and low charge linear density

A line density, small diameter technology, applied in the field of detonating cord or detonator extension line, can solve the problems of strong shock waves, large diameter, serious pollution, etc., to achieve the effect of ensuring product quality, heat generation control, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

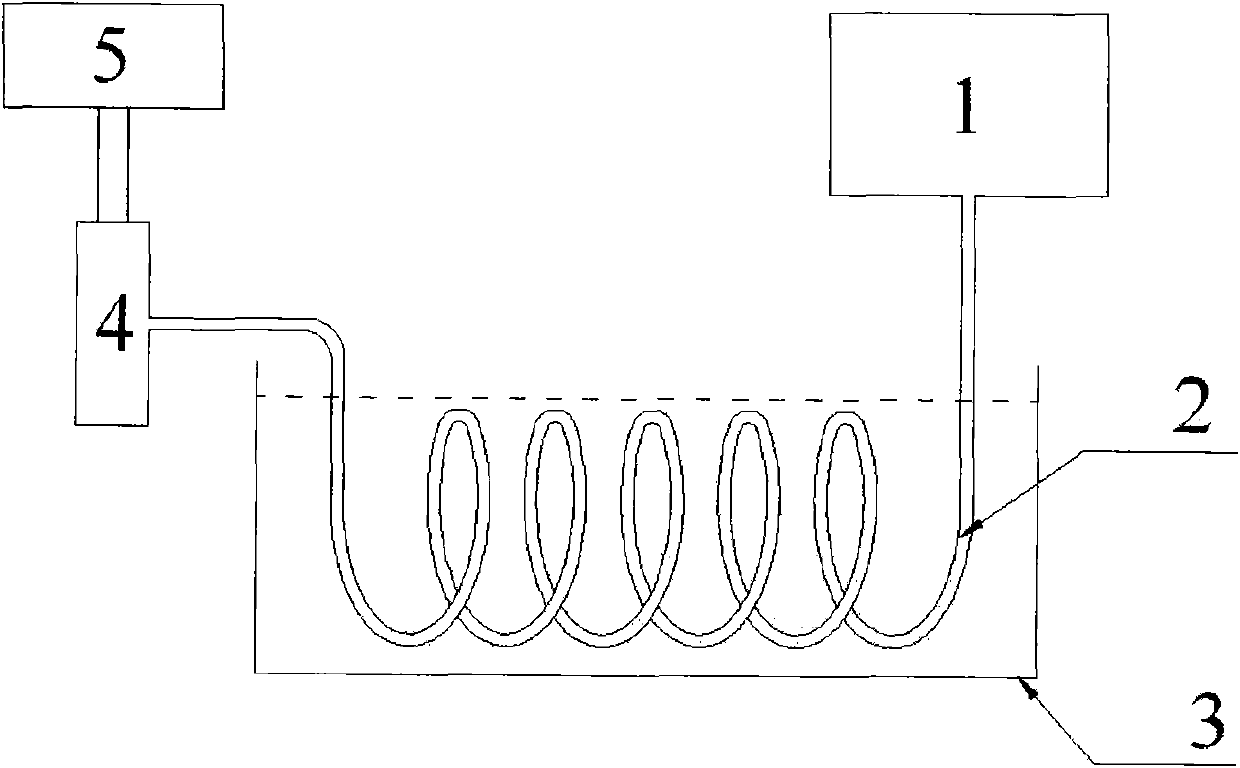

[0027] Embodiment 1 utilizes thermoplastic method charge

[0028] Firstly, according to the size (inner diameter, outer diameter) of the detonating cord of the designed small diameter and low linear density charge, the charge linear density, and the initial size of the tube body (inner diameter, outer diameter), use the formula ρ 1 = ρ 2 · D 1 2 - d 1 2 D 2 2 - d 2 2 ( g / m ) , The calculated initial charge linear density ρ 1 , combined with the initial length of the ...

Embodiment 2

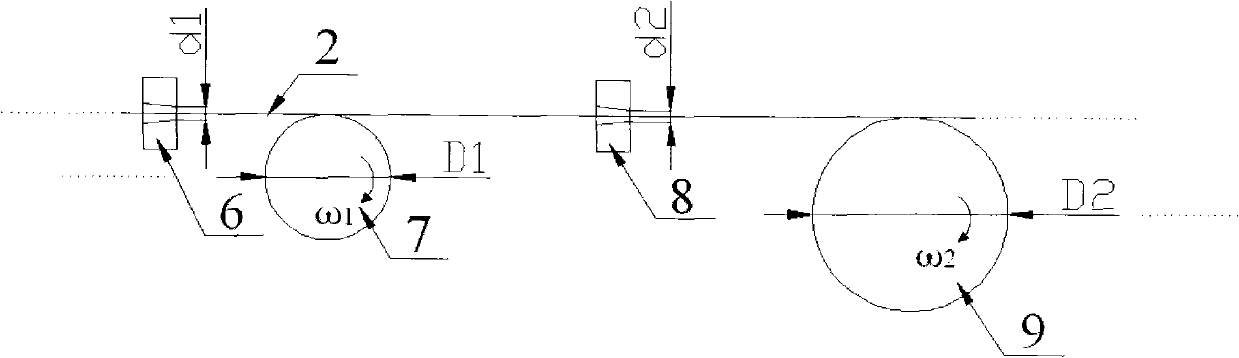

[0030] Embodiment 2 Use linear continuous drawing equipment to make detonating cord with small diameter and low linear density charge

[0031] see figure 2 , the charged initial tube body 2 passes through two molds 6 and 8 in turn, so that its radial dimension changes from d of the initial tube body to d after passing through the mold 6 1 , becomes d after the second drawing of die 8 2 . Control the diameter and rotational speed of the pulling rollers 7 and 9, so that the linear velocity of the pipe body is within a reasonable range, so that the heat caused by deformation can be released quickly, so as to avoid adverse changes of explosives or delay charges inside the pipe body.

[0032] When aluminum pipes are used, the linear speed of the finished pipe body must be controlled within 85 m / min. Generally speaking, the linear velocity of the last pulling roller (ie the linear velocity of the finished pipe body) ranges from 8.0 to 85m / min. In actual production, the speed of...

Embodiment 3

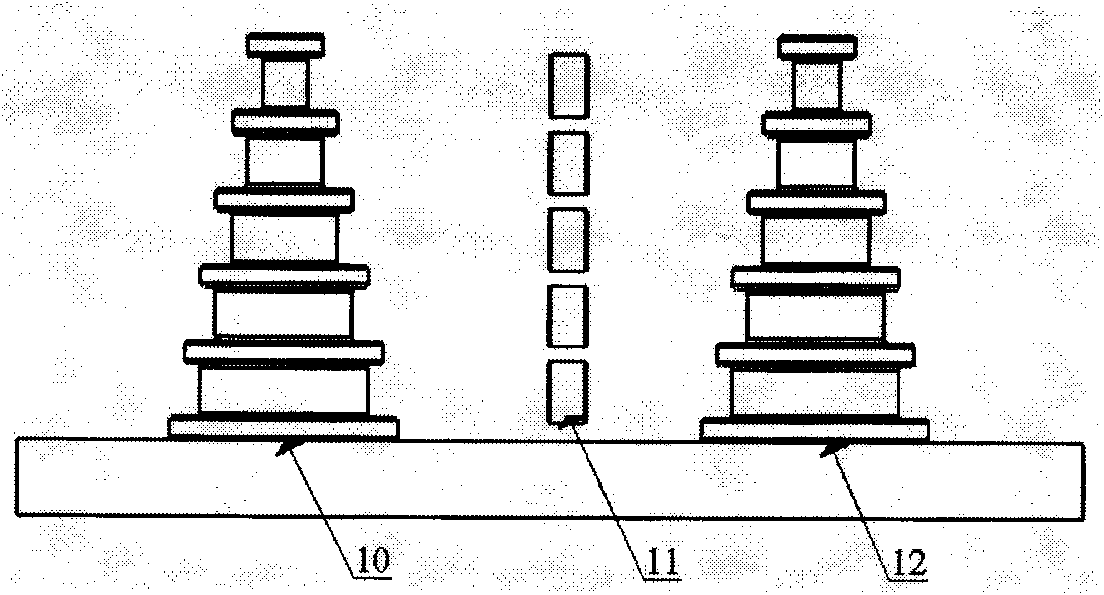

[0034] Embodiment 3 Use the tower wheel type continuous drawing equipment to make the detonating cord or detonator extension line of small diameter and low linear density charge

[0035] In the actual production process, parameters such as the number of molds used in a single drawing and the elongation coefficient can be adjusted as needed. see image 3 , using 5 sets of molds to pull the detonating cord of the small diameter, low linear density charge from 8.0mm in diameter to 6.0mm in diameter. The size arrangement of the mold group 11 is: 8.0mm, 7.5mm, 7.0mm, 6.5mm, 6.0mm. Through processes such as head rolling and die piercing, the detonating cord with an outer diameter of 8.5mm or the initial pipe body of the delay line filled with explosives or delay charges is wound on two sets of tower wheels 10,12. Turn on the control equipment, the motor drives the tower wheel to rotate, and the tower wheel pulls the detonating cord or the extension line tube to pass through the 8....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com