High temperature energy-saving tunnel kiln for physical thermal circulation application

A tunnel kiln and physical heat technology, which is applied in the field of high temperature energy-saving tunnel kiln for physical heat cycle utilization, can solve the problems of high energy consumption and insufficient utilization of thermal energy, and achieve the effect of expanding the application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

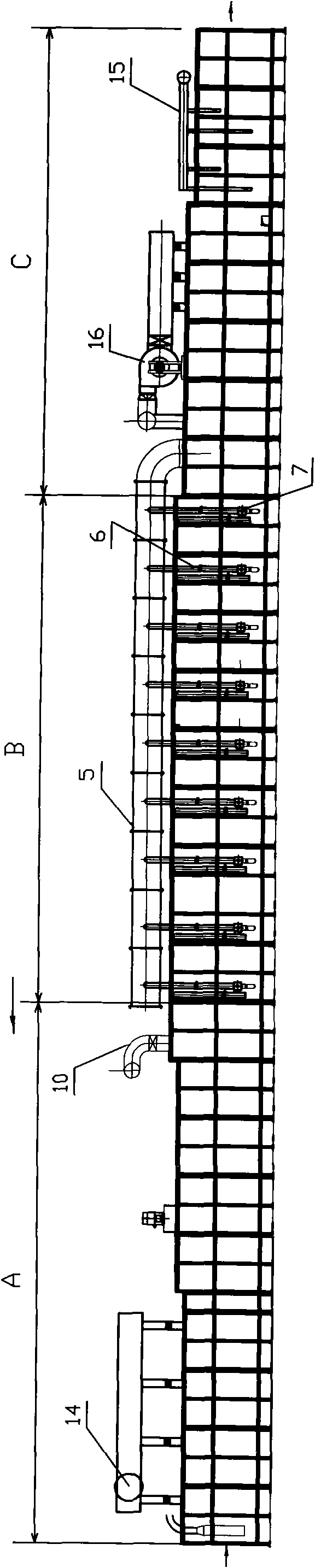

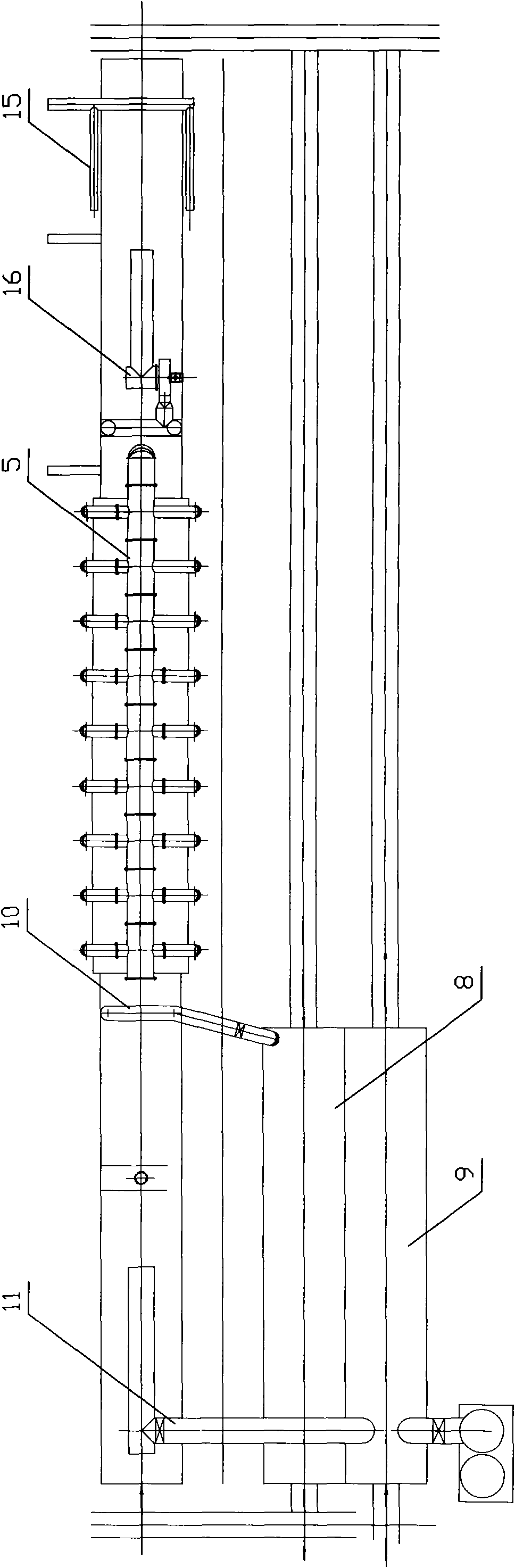

[0026] Depend on Figures 1 to 14 It can be seen that the present invention is composed of a preheating zone A, a firing zone B and a cooling zone C, and a billet drying room 8 and a billet drying room 9 are arranged on one side of the kiln body, and its features include:

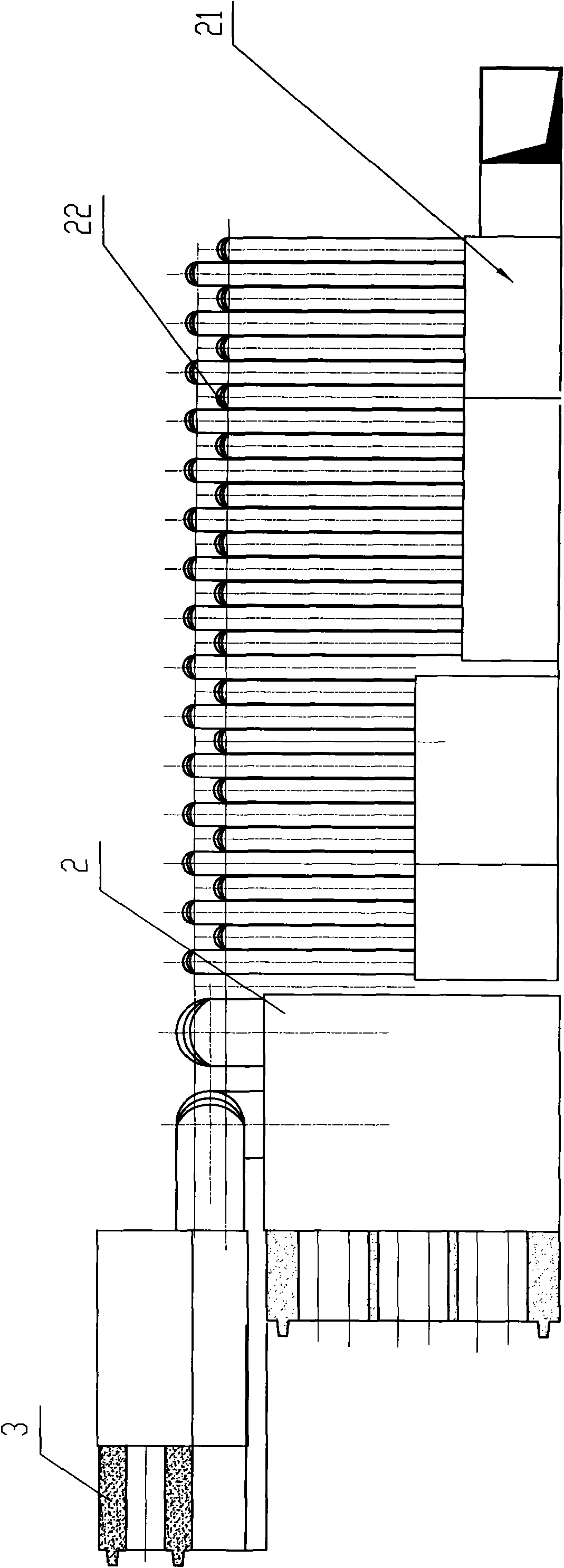

[0027] A metal tubular air preheater 2 is installed in the furnace of the middle temperature section of the cooling zone C of the tunnel kiln, and a silicon carbide air preheater 3 made of non-metallic materials is installed in the furnace of the high temperature section of the cooling zone, wherein the metal tubular preheater 2 One end is connected to the fan 1, the other end is connected to the silicon carbide air preheater 3, the other end of the silicon carbide air preheater 3 is connected to the high temperature air duct 5, and then the high temperature air duct 5 passes the preheated combustion air through the high temperature air duct The air valve 6 is connected to the high temperature burner 7 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com