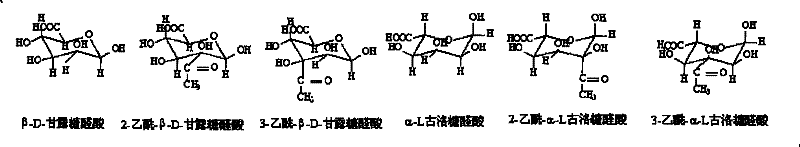

Application and method of using pseudomonas mendocina NK-01 for production of brown alginate oligosaccharides

A technology for the production of fucoidan oligosaccharides and Pseudomonas spp. is applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., which can solve the problems of high price, easy inactivation of enzymes, and low yield, and achieve a fermentation cycle Short, simple process, overcome the cumbersome effect of separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1, one-step fermentation to prepare fucoidan oligosaccharides (fermentation under low carbon and low nitrogen conditions)

[0022] The pre-cultivation is in the L-test tube, add 5ml of LB medium by aseptic operation, insert a single colony of NK-01 strain with a sterile toothpick, and cultivate at 30°C and 120rpm for 12h. Inoculate 0.5 ml of the pre-culture into a 500 ml Erlenmeyer flask containing 100 ml of LB medium, and culture with shaking at 150 rpm at 30°C for 24 hours. Sterile centrifuge at 6000g for 10min at 4°C, discard the supernatant, shake and mix with sterile phosphate buffer in a centrifuge tube, centrifuge again at 4°C, 6000g for 12min, discard the supernatant. The bacteria without LB medium were aseptically inserted into a 1-liter fermentation device with controllable oxygen stirring, which contained 1 liter of medium 1 (pH 7), and cultured at 30° C. for 48 hours with aeration. After the fermentation, the cells were removed by centrifugation, an...

Embodiment 2

[0023] Example 2, two-step fermentation to prepare fucoidan oligosaccharides (fermentation under low carbon and nitrogen-free conditions)

[0024] The pre-cultivation is in the L-test tube, add 5ml of LB medium by aseptic operation, insert a single colony of NK-01 strain with a sterile toothpick, and cultivate at 30°C and 120rpm for 12h. Inoculate 0.5 ml of the pre-culture into a 500 ml Erlenmeyer flask containing 100 ml of LB medium, and culture with shaking at 150 rpm at 28°C for 24 hours. Sterile centrifuge at 6000g for 10min at 4°C, discard the supernatant, shake and mix with sterile phosphate buffer in a centrifuge tube, centrifuge again at 4°C, 6000g for 12min, discard the supernatant. The bacterial cells without LB medium were aseptically inserted into 10 bottles of 500ml Erlenmeyer flasks containing 100ml of medium 2 (pH 7), cultured at 30°C with shaking at 150rpm. Finish fermentation after 48 hours, following steps are with embodiment 1.

Embodiment 3

[0025] Example 3, Preparation of Fucoidan Oligosaccharides by One-step Fermentation (Fermentation under Low Carbon and Low Nitrogen Conditions)

[0026] The pre-cultivation is in the L-test tube, add 5ml of LB medium by aseptic operation, insert a single colony of NK-01 strain with a sterile toothpick, and cultivate at 30°C and 120rpm for 12h. Inoculate 0.5 ml of the pre-culture into a 500 ml Erlenmeyer flask containing 100 ml of LB medium, and culture with shaking at 150 rpm at 30°C for 24 hours. Sterile centrifuge at 6000g for 10min at 4°C, discard the supernatant, shake and mix with sterile phosphate buffer in a centrifuge tube, centrifuge again at 4°C, 6000g for 12min, discard the supernatant. The bacteria without LB medium were aseptically inserted into a 1-liter fermentation device with controllable oxygen stirring, which contained 1 liter of medium 3 (pH 6), and cultured at 28°C for 60 hours with aeration. Following steps are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com