Totally-closed sand grinding technology for coating production

A fully enclosed, sanding technology, used in the direction of smoke removal, cleaning methods and utensils, grain handling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment one, make solvent type antirust primer

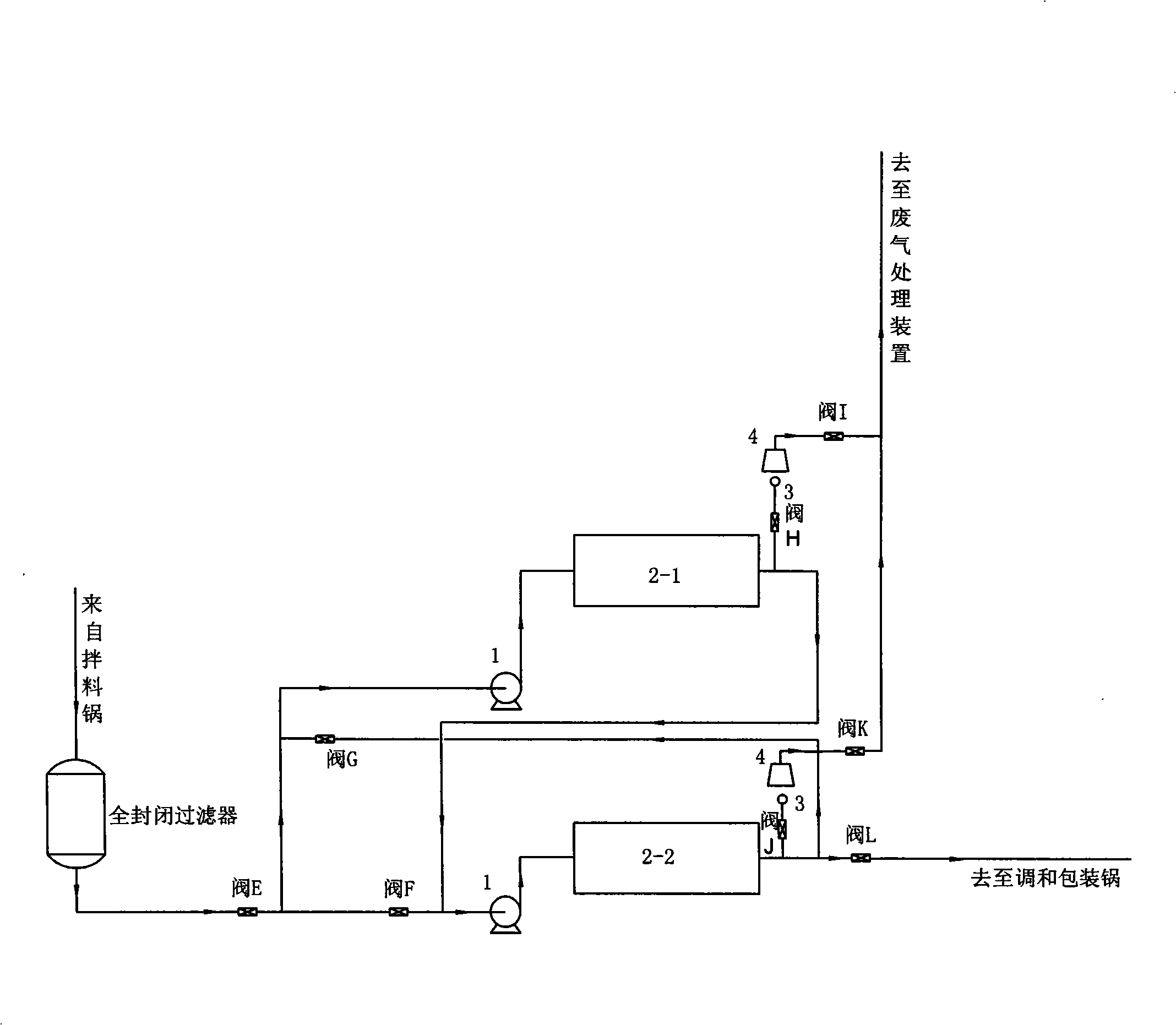

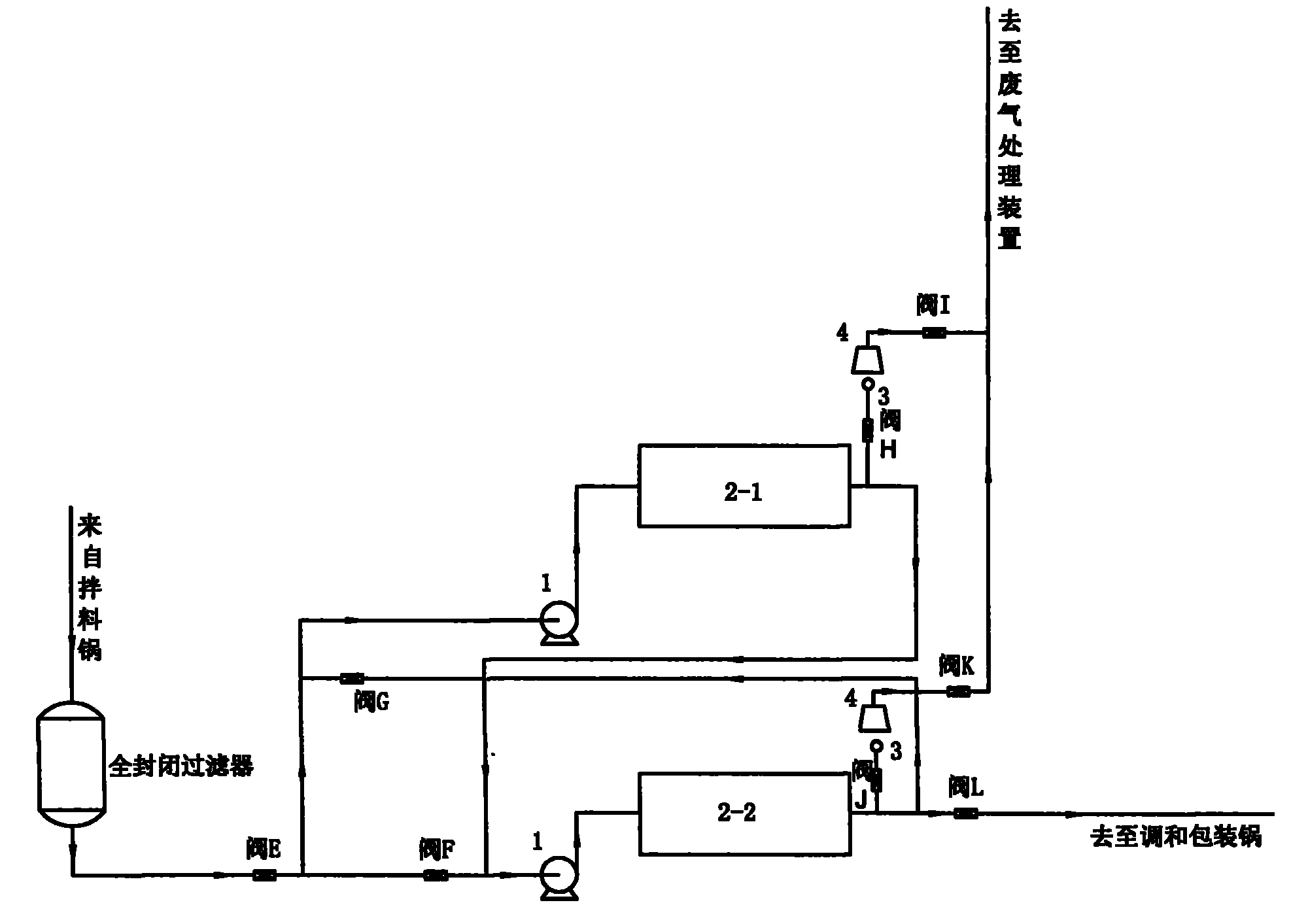

[0024] 1. Firstly, the pre-mixed paint slurry is transported from the mixing pot to the fully enclosed filter through the pipeline with gravity as power, and is initially filtered through the fully enclosed filter in the mesh screen with a mesh size of 4-6 mm. According to the fineness requirements, only one horizontal sand mill needs to be connected;

[0025] 2. The filtered paint slurry is powered by the pneumatic diaphragm pump 1 on the horizontal sand mill 2-2 to the horizontal sand mill 2-2 for sand grinding, and the horizontal sand mill unit 2-2 is lowered. The pressure setting value of the pneumatic diaphragm pump 1 (set to 0.15Pa), open the valve E and valve F, start the pneumatic diaphragm pump 1 and the horizontal sand mill 2-2, open the waste gas collection port 4 and valve K at the same time open the fine The valve J of the degree monitoring port 3, measured at this time the fineness of the paint slurry is...

Embodiment 2

[0026] Embodiment two, make solvent type white alkyd topcoat

[0027] 1. First, the pre-mixed paint slurry is transported from the mixing pot to the closed filter through the pipeline, and in the mesh sieve with a mesh size of 4-6 mm, after preliminary filtration through the fully closed filter, according to the fineness requirements Choose two horizontal sand mills to use in series;

[0028] 2. The filtered paint slurry is powered by the pneumatic diaphragm pump 1 on the horizontal sand mill and sent to the horizontal sand mill unit for sand grinding, and the pneumatic diaphragm pump on the 2-1 and 2-2 sand mill units is lowered 1 pressure setting value (set to 0.2MPa), open valve E, valve F, start pneumatic diaphragm pump 1 and horizontal sand mill 2-1, horizontal sand mill 2-1 is working, and open the exhaust gas collection port 4. Open the valve H of the fineness monitoring port 3 while the valve I is at the same time. It is measured that the fineness of the paint slurry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com