Image forming apparatus

一种图像、设备的技术,应用在图像形成设备领域,能够解决定影不足、调色剂图像和激光照射对位精度低、通用性低等问题,达到缩短开始时间、节省电力能源、提高光泽性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

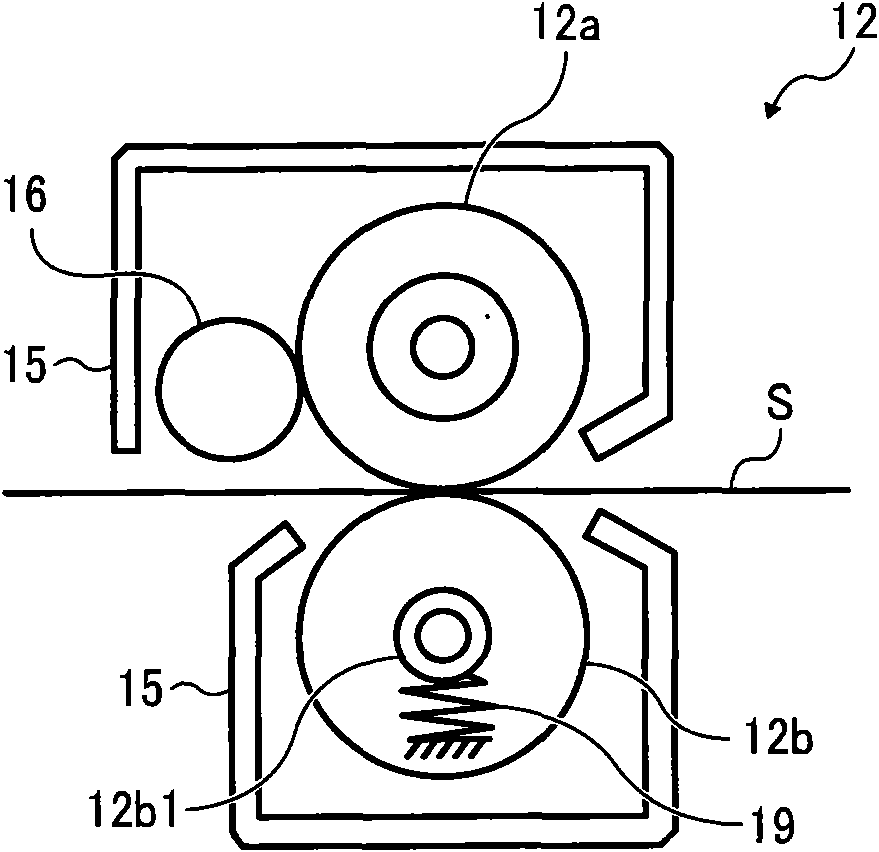

[0163] First, a first embodiment of the present invention will be described.

[0164] A first embodiment of the present invention provides an image forming apparatus capable of using the toner used in the thermal fixing method while suppressing power consumption by providing both a heating method fixing device and a pressurizing method fixing device. Toner, recording materials, image forming equipment with high versatility, and while saving energy, can improve the glossiness of the toner surface to obtain an image close to photographic quality, further, according to whether glossiness is required The paper can be automatically or manually selected whether to use the function of the fixing device by pressure.

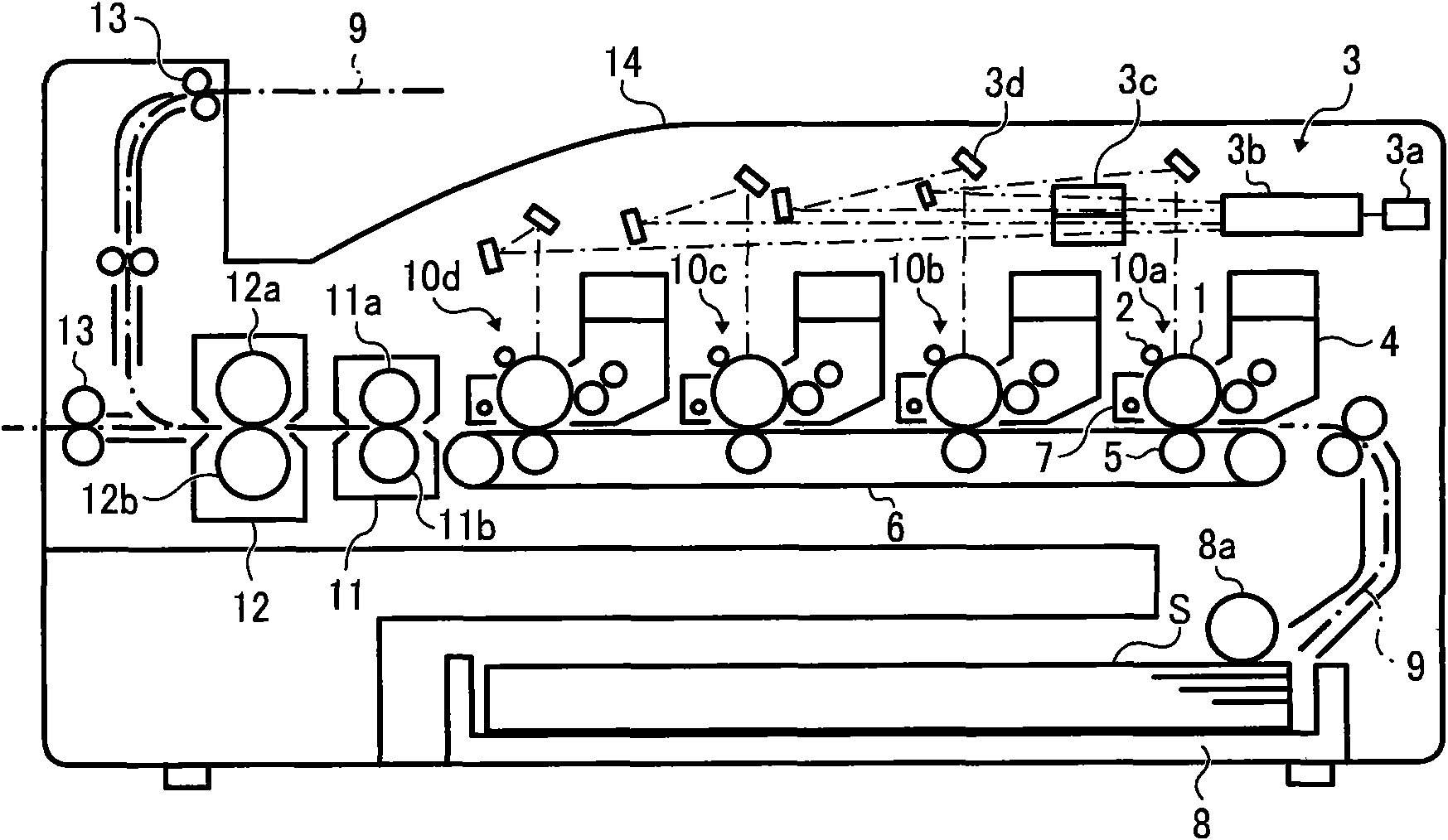

[0165] figure 1 Shown is a schematic configuration diagram of an image forming apparatus which is a configuration example of the first embodiment.

[0166] figure 1The image forming apparatus having the configuration shown in the figure is moved along a conveying be...

Embodiment 2

[0201] Next, a second embodiment of the present invention will be described.

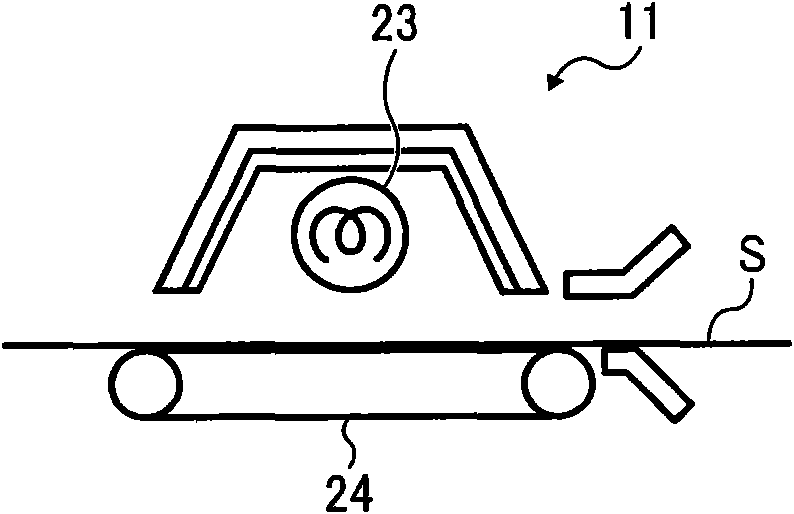

[0202] A second embodiment of the present invention provides an image forming apparatus capable of using toner used in a thermal fixing system while suppressing power consumption by providing both a heating system fixing device and a pressure system fixing device. , recording materials, to achieve a highly versatile structure, especially the structure formed by using a heating device heated by radiant heat, and furthermore, by setting the roller pair of the fixing device of the pressurized method, it is possible to prevent the roller pair from contacting and causing damage. generated problems.

[0203] FIG. 13 is a schematic configuration diagram of an image forming apparatus as a configuration example of the second embodiment. The basic configuration, operation and figure 1 The image forming apparatuses shown are the same, and the description of Embodiment 1 can be referred to.

[0204] The pre...

Embodiment 3

[0227] Next, a third embodiment of the present invention will be described.

[0228] A third embodiment of the present invention provides an image forming apparatus capable of using toner and plain paper used in thermal fixing by providing both a heating fixing device and a pressure fixing device. With a highly versatile structure, the start time can be shortened to achieve energy saving. In addition, by setting the toner transfer process and heating process along the peripheral surface of the same recording material conveying belt, the recording material is separated from the conveying belt. By softening the toner and holding it in the recording material, it is possible to prevent toner scattering and image disturbance during separation. Furthermore, by disposing the pair of pressure rollers of the fixing device of the pressure system spaced apart, it is possible to prevent damage that may occur when the pair of pressure rollers come into contact.

[0229] Figure 20 Shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com