Vehicle hvac and battery thermal management

A HVAC and battery technology, which is applied to electric vehicles with internal combustion engines and fuel cell vehicles, can solve problems such as difficulties, low heat dissipation, and low heat transfer coefficient, and achieve the effect of maximizing battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

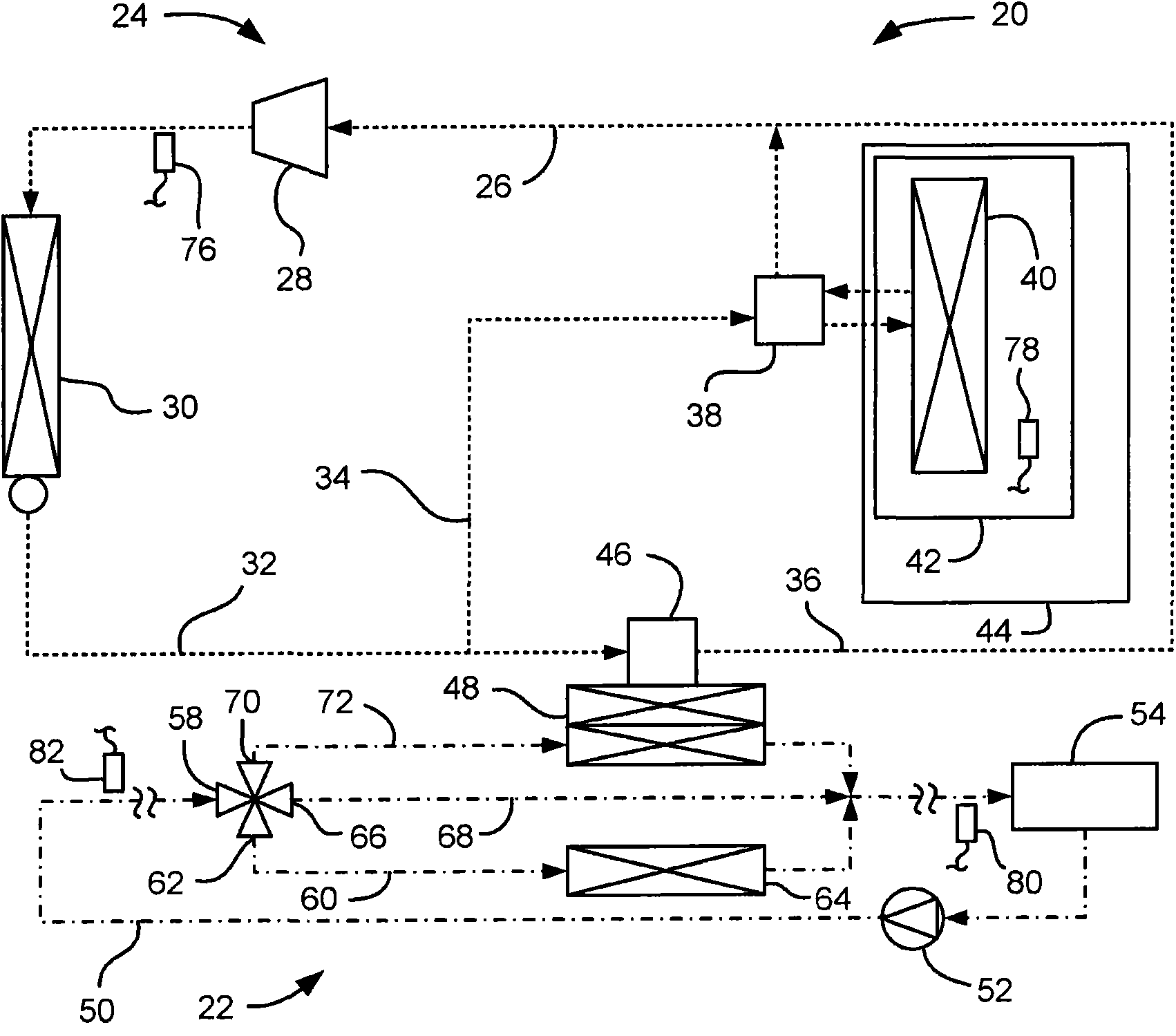

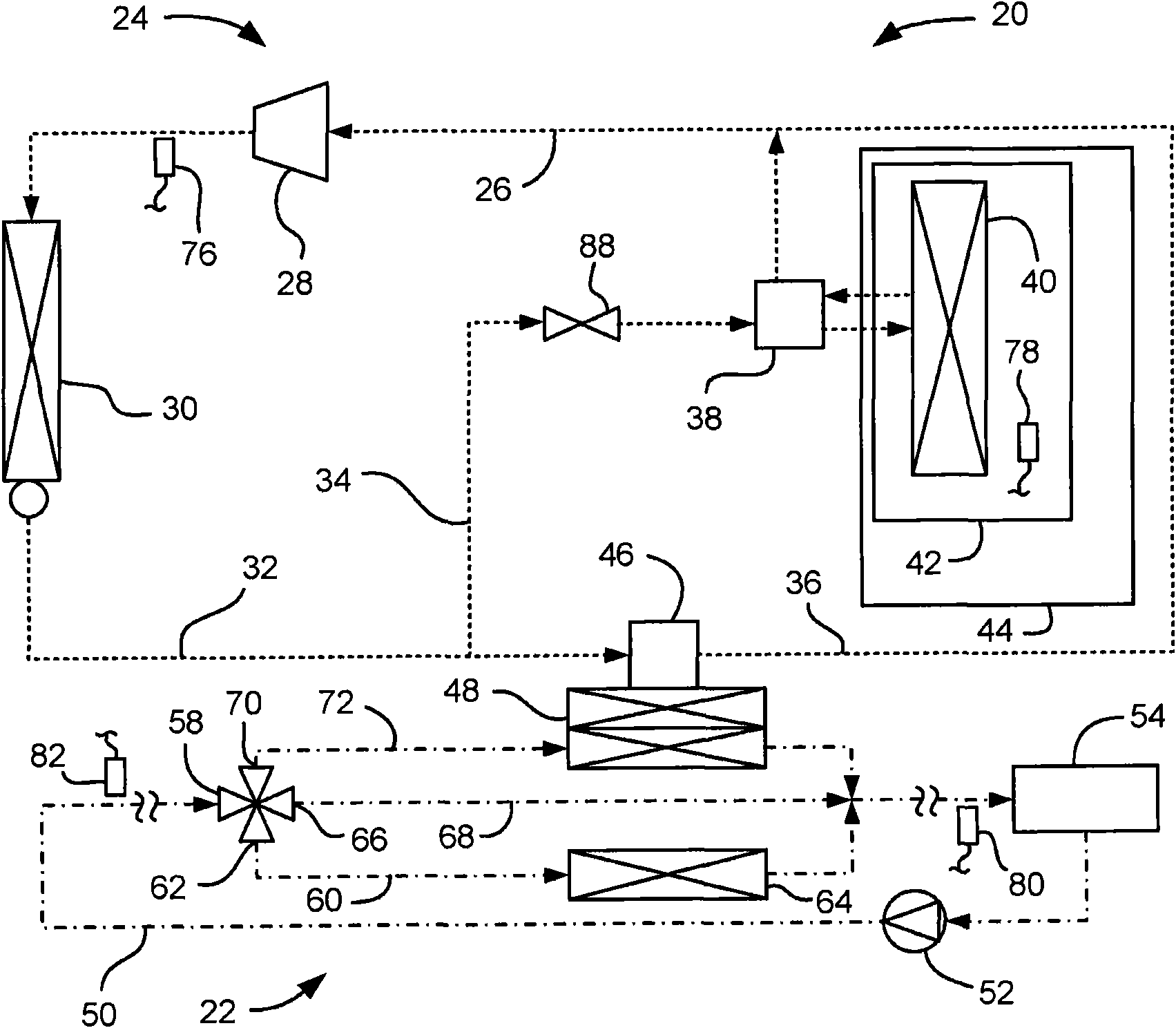

[0011] refer to figure 1 , the portion of the vehicle generally indicated at 20 includes the heating, ventilation and air conditioning (HVAC) and battery thermal systems 22 of the vehicle. The system 22 includes an air conditioning section 24 having a refrigerant circuit 26 . The refrigerant circuit 26 includes a refrigerant compressor 28 and a condenser 30 . Refrigerant compressor 28 may be electrically driven with the ability to adjust compressor speed (RPMs) during operation. The condenser 30 guides the refrigerant into the refrigerant pipeline 32 , and the refrigerant pipeline 32 is branched into a first branch 34 and a second branch 36 of the refrigerant circuit 26 .

[0012] The first branch 34 directs refrigerant through an evaporator thermal expansion valve 38 (or other expansion device) into an evaporator 40 located in an HVAC module 42 in a passenger cabin 44 of the vehicle 20 . Refrigerant exiting the evaporator 40 is directed through the return portion of the ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com