Integrated fume dustfall stem superheater

A superheating device and flue gas technology, applied in steam superheating, steam generation, waste heat treatment, etc., can solve problems such as increased investment costs, large floor space, and complex systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] specific implementation plan

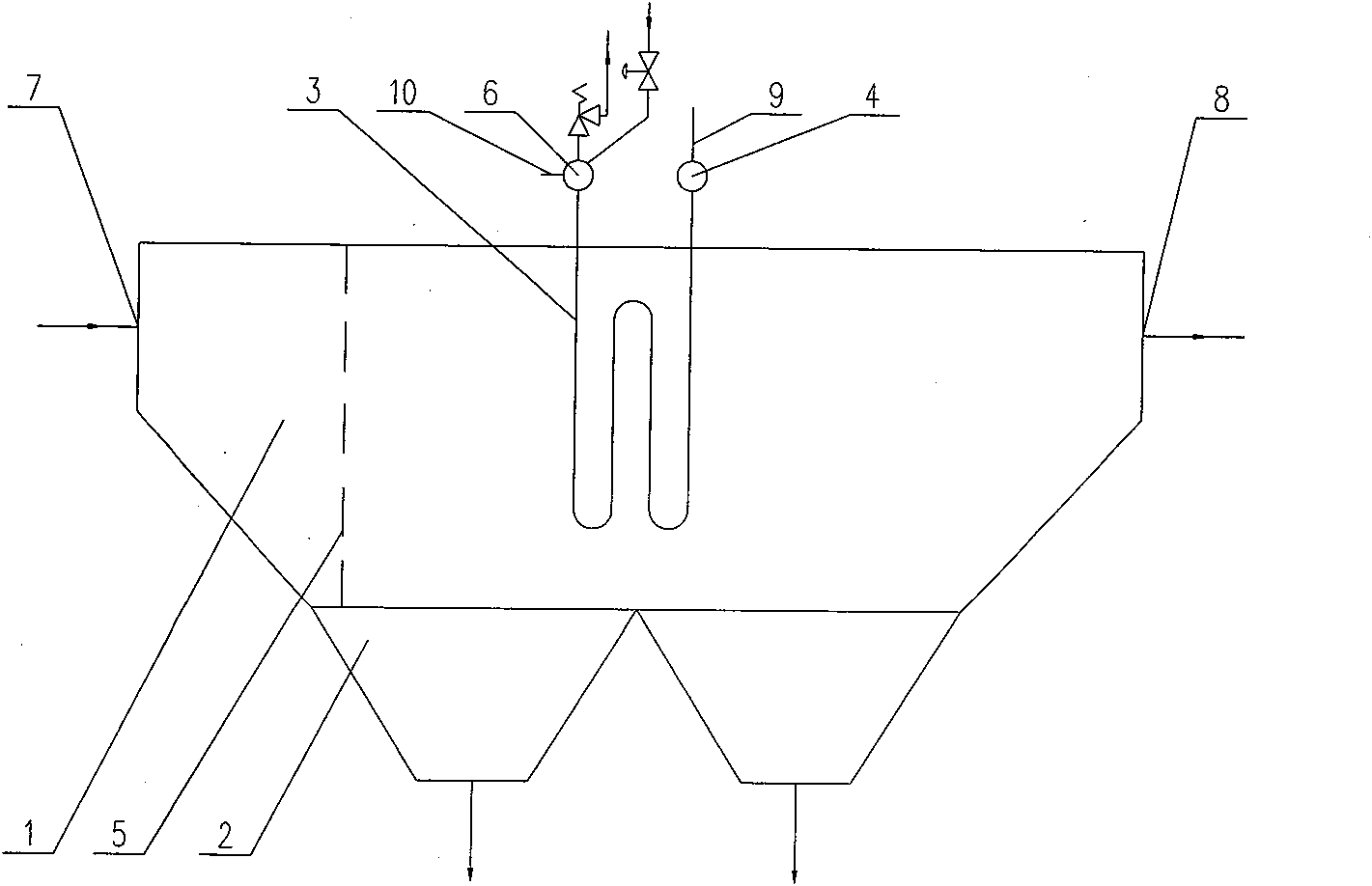

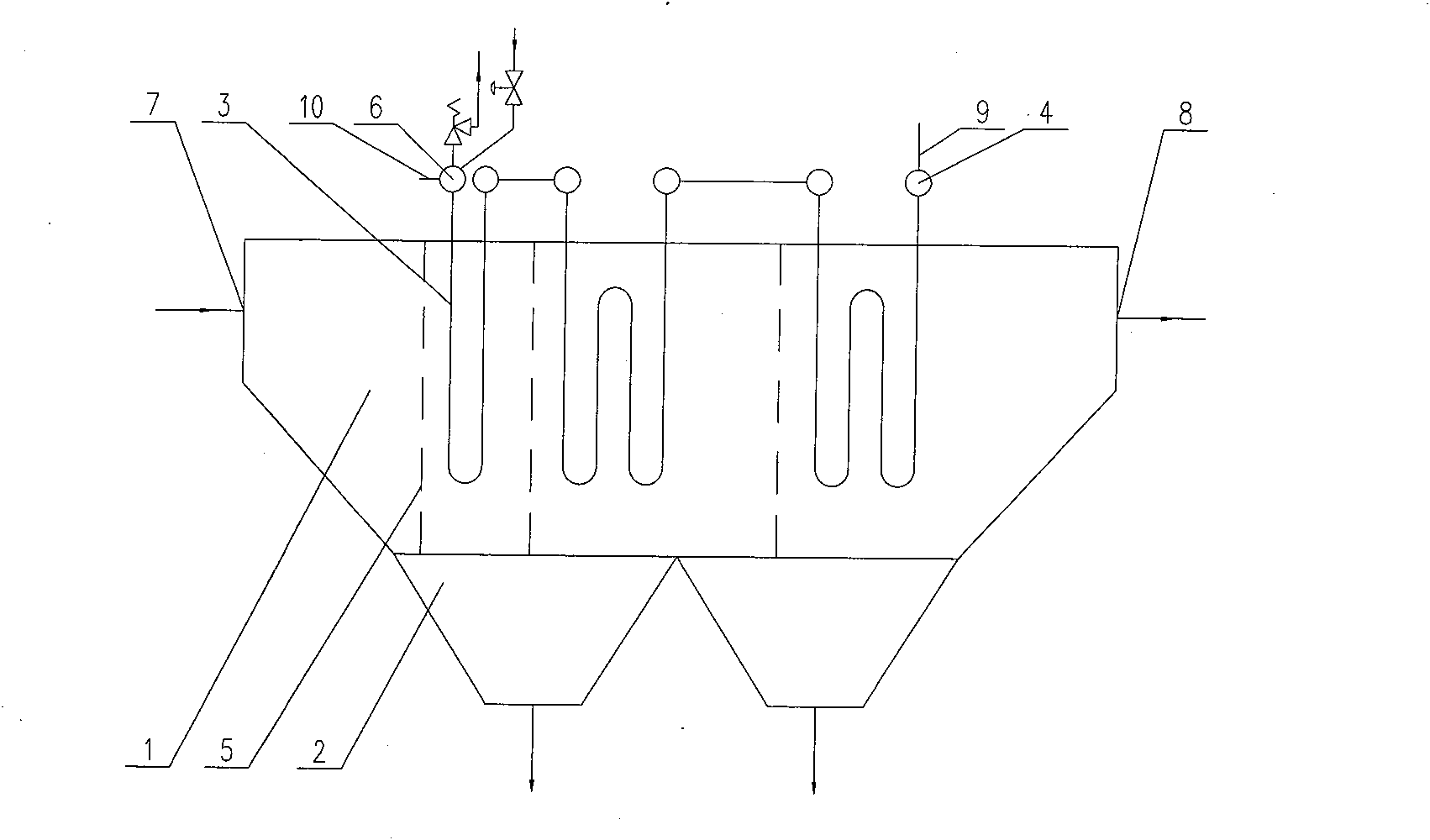

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] see Attachment.

[0013] The integrated flue gas and dust reduction steam superheating device is composed of a shell 1, an ash chamber 2, a tube bundle 3, a tube bundle header 4, a tube bundle header 6, a baffle plate 5, a safety valve, and a steam temperature regulating valve. The shell 1 is provided with a flue gas inlet 7 and a flue gas outlet 8, and the shell is provided with a heat exchange panel composed of a tube bundle 3, a tube bundle header 4, and a tube bundle header 6, and the tube bundle 3 is composed of uniformly arranged hollow tubes. The hollow tube adopts finned tube or light tube. The baffles 5 are arranged in the housing 1 , and the baffles 5 are parallel or perpendicular to the radial direction of the tube bundle 3 , and there are one or more than one baffles 5 . The ash accumulation chamber 2 passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com