Process for producing polyester spunbonded pre-oriented yarn from waste polyester bottle chips

A technology of pre-oriented yarn and production process, applied in the field of polyester filament manufacturing, can solve the problems of high spinning cost and large waste of petroleum resources, and achieve the effects of saving materials, eliminating bridging, and improving the humidity of air-conditioning side air.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

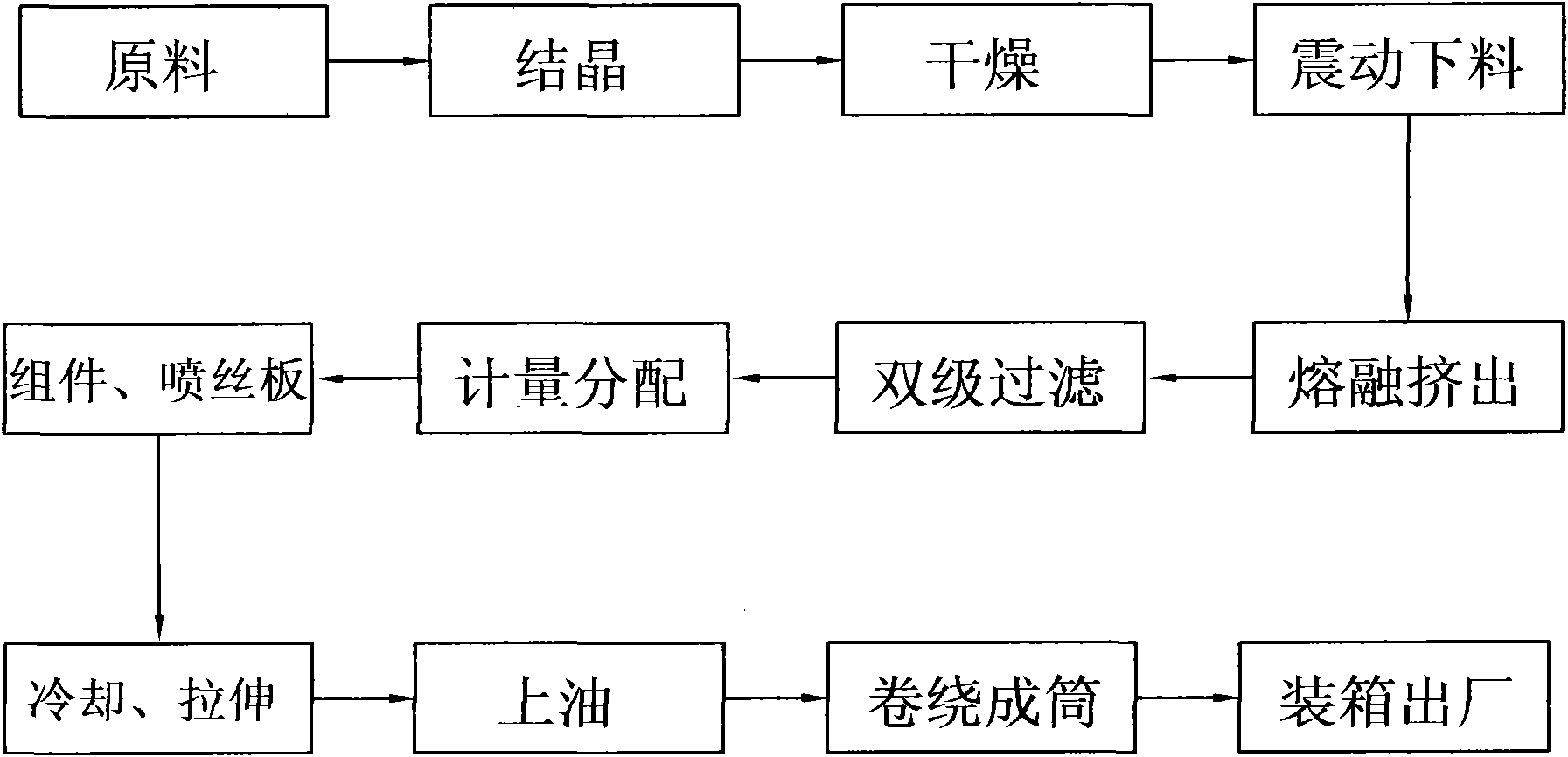

[0024] The production process of polyester pre-oriented yarn spun from waste polyester bottle flakes, combined with figure 1 shown. Using waste PET bottles as raw materials, PET bottle flakes are obtained by sorting, crushing, and cleaning, and the bottle flakes are crystallized and dried. The crystallization temperature is 165°C, and the fan frequency is 40-50Hz. In the drying step, the drying temperature is controlled at 150°C, and the drying air pressure is 1.5Kg / Cm 2 , the drying time is 300min, and the moisture content of the bottle flakes can reach ≤30ppm. Due to the characteristics of low melting point and high viscosity of the waste bottle flakes, continuous crystallization and drying under high temperature conditions are likely to cause bottle flake accumulation, adhesion, uneven feeding speed, etc., resulting in the failure of continuous crystallization and drying of bottle flakes. In view of these bad characteristics of waste bottle flakes, by increasing the area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com