Quenching ring for gasification furnace

A chilling ring and gasifier technology, which is applied in the gasification of granular/powdered fuel, the manufacture of combustible gas, and the petroleum industry. It can solve problems such as uneven distribution of chilling liquid, damage to the gasifier, and easy blockage. To achieve the effect of prolonging the heat exchange time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

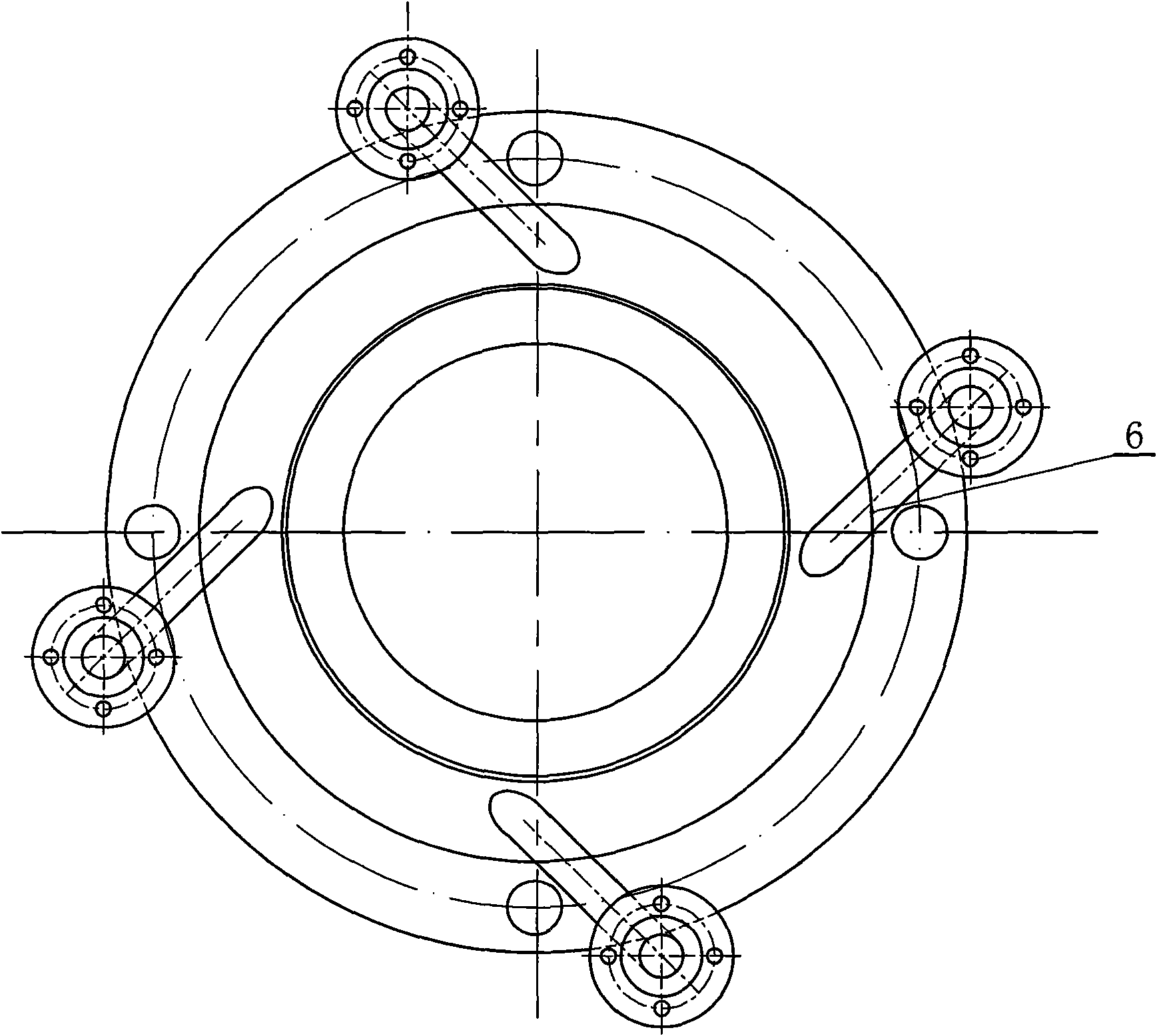

[0012] A gasifier quench ring, such as figure 1 , 2 As shown, it includes a downcomer 10, an annular outer lip ring 2, an annular inner lip ring 3 and a coolant delivery pipe 6. The annular outer lip ring and the annular inner lip ring form a quench liquid distribution chamber 4, and the annular inner lip ring forms a quenching liquid distribution chamber 4. The lip ring is fixedly connected with the downcomer 10, and the quenching liquid annular gap 7 is formed between the lower part of the annular outer lip ring 2 and the downcomer 10, and it is characterized in that the outside of the quenching liquid distribution chamber 4 is fixedly connected with a cooling liquid The delivery pipe 6, the coolant delivery pipe 6 communicates with the quench liquid distribution chamber 4, the center line of the coolant delivery pipe 6 forms an included angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com