Composite oil gas separation method and composite oil gas separator

A technology of oil-gas separator and separation method, which is applied in the direction of machines/engines, swirl devices, crankcase ventilation, etc., which can solve the problems of high-efficiency oil-gas separation, achieve high-efficiency separation, high cost performance, and avoid flow short-circuit effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

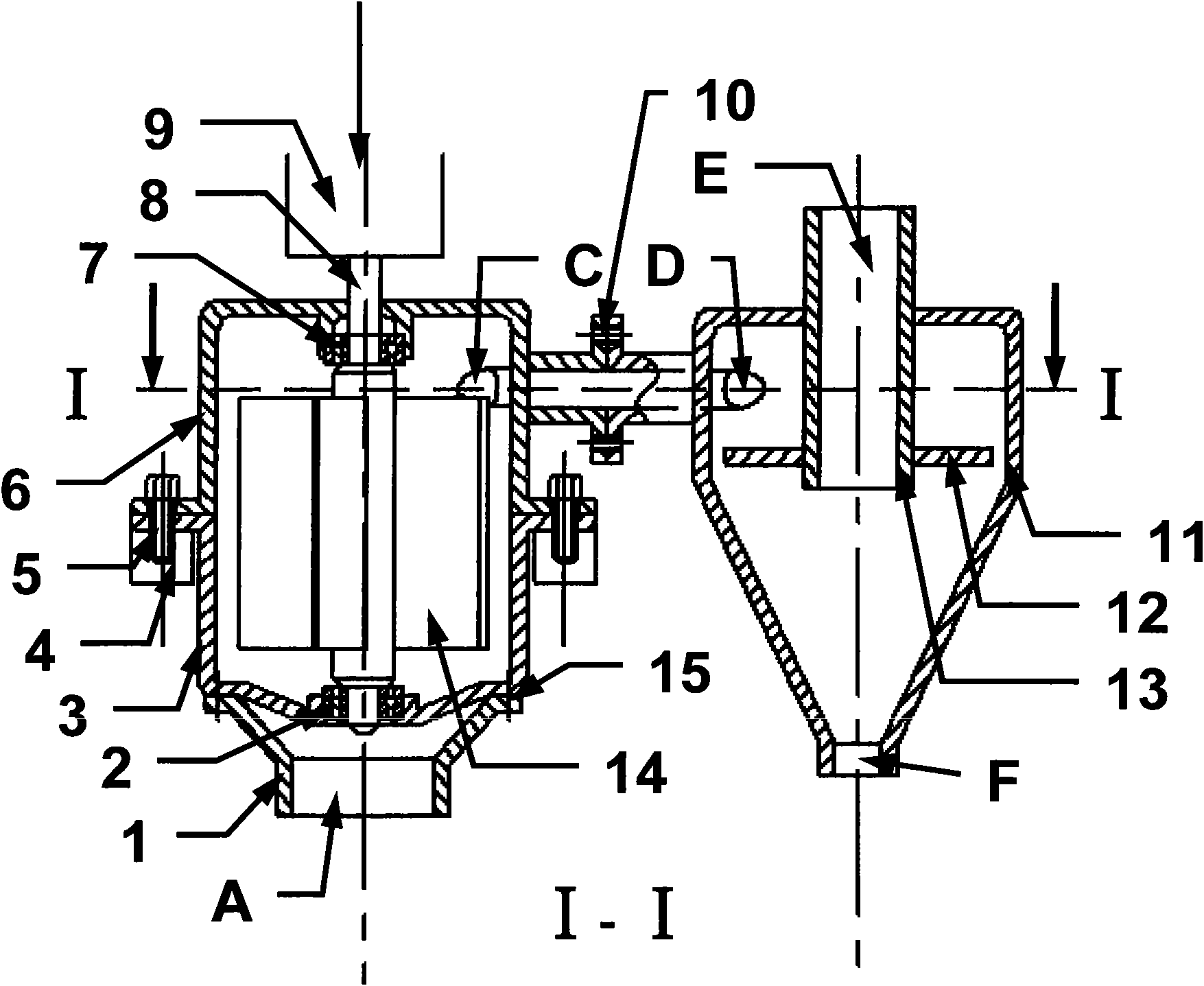

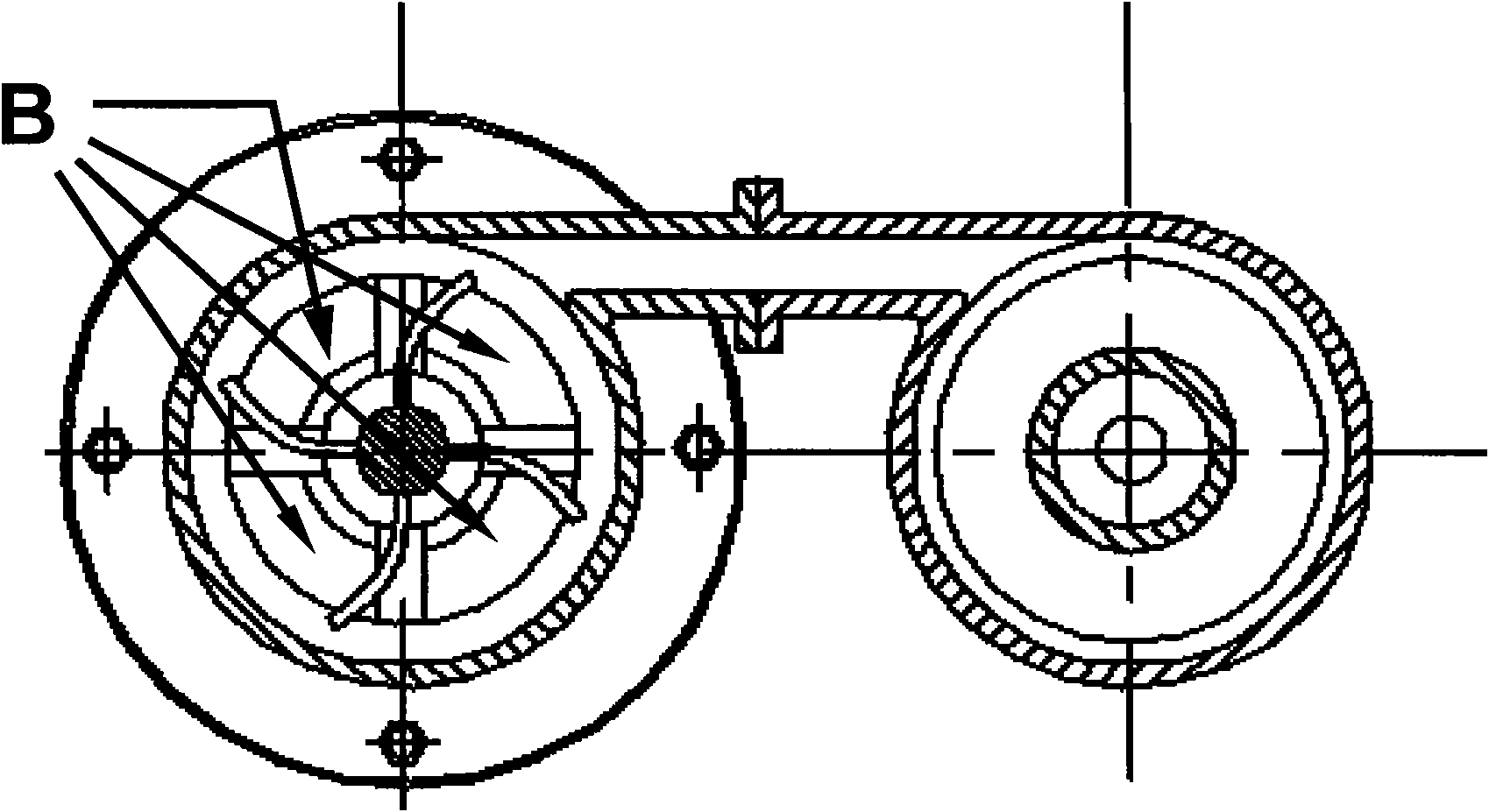

[0023] Below in conjunction with the example shown in the accompanying drawings, further illustrate the specific content of the present invention and its working process.

[0024] A compound oil-gas separation method combining active and passive centrifugal separation principles. Among them, the active centrifugal separator drives the transmission shaft 8 through the external power source 9, drives the blades 14 to rotate, sucks the crankcase blow-by gas into the separation chamber, and controls the speed of the transmission shaft 8 in a closed loop according to the variation of the crankcase blow-by gas with the working conditions of the internal combustion engine , to achieve high-efficiency separation of oil and gas under all working conditions, and to maintain the crankcase pressure within the set range. The pressurized and accelerated exhaust gas enters the passive cyclone separator along the tangential direction, which improves the separation efficiency and makes up for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com