Moisture-curable polyurethane hot-melt adhesive, laminates made with the same, and moisture-permeable film

A moisture-curable, hot-melt adhesive technology, used in polyurea/polyurethane adhesives, adhesive types, adhesives, etc., to achieve excellent moisture permeability, excellent abnormal bond strength and water-resistant bond strength, Use high-value effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0132] Embodiment 1 "moisture curing type polyurethane hot melt adhesive A"

[0133] In a 1-liter 4-neck flask, add: polyester polyol (a-1 -1) 15 parts by mass; 14.4 parts by mass of neopentyl glycol, 34.5 parts by mass of 1,6-hexanediol and 51 parts by mass of adipic acid are obtained by reacting 20 parts by mass of crystalline polyester polyol (a-2-1) with a number average molecular weight of 2000 in 15 mass % of methyl-1,3-propylene; and polyethylene glycol ( a-3-1) 65 parts by mass. It heated under reduced pressure at 120 degreeC, and dehydrated until the water content in the flask became 0.05 mass %.

[0134] Next, the temperature in the aforementioned flask was cooled to 70°C, and then 18 parts by mass of 4,4'-diphenylmethane diisocyanate was added, and reacted at 90°C for 3 hours until the NCO content became constant, thereby obtaining a moisture-curable polyurethane Hot melt adhesive A. The viscosity of the adhesive A at 125°C was measured with a cone-plate viscome...

Embodiment 2~7 and comparative example 1~9

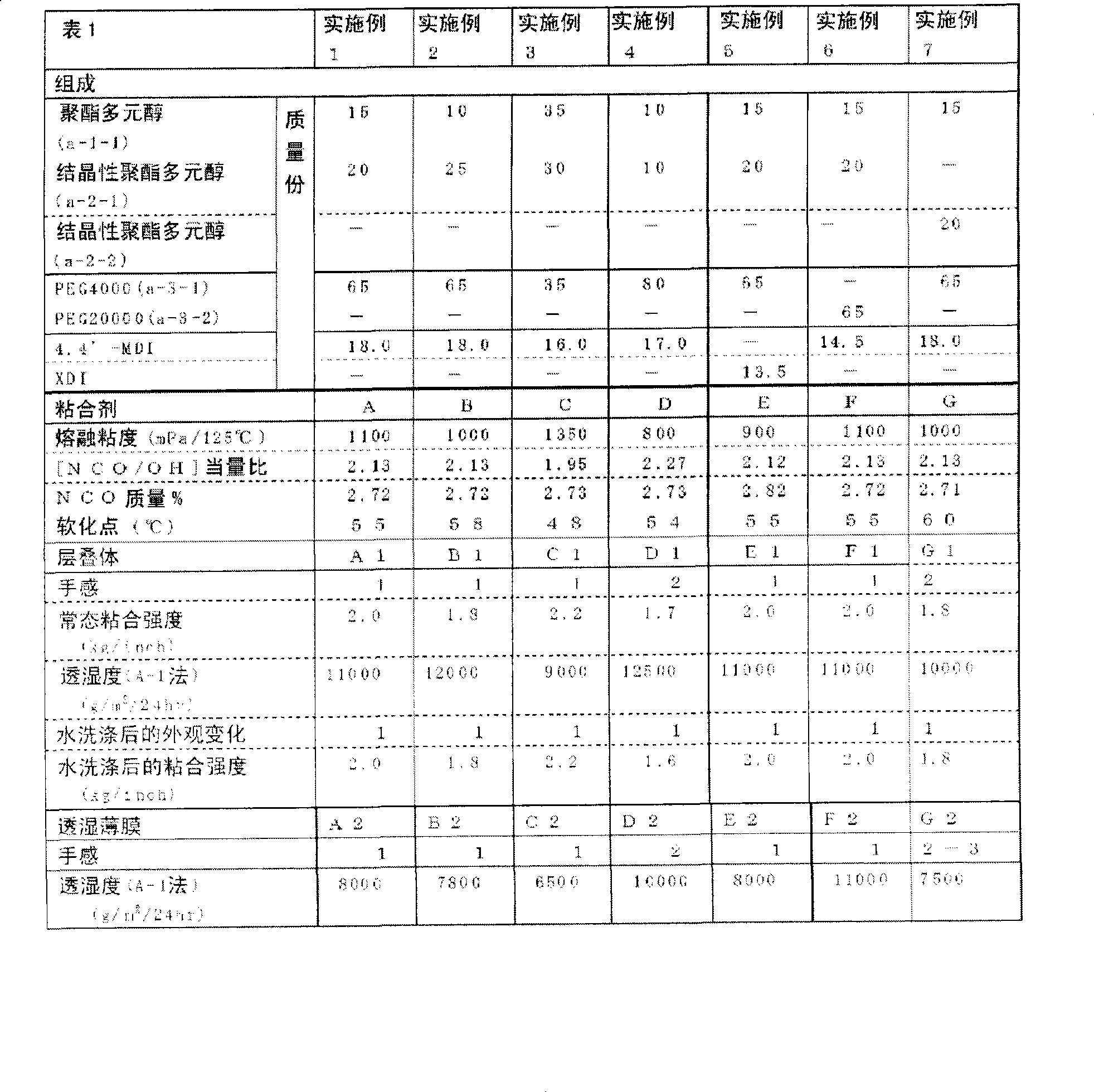

[0141] Except that the compositions of the polyol and polyisocyanate were changed to the following Tables 1 to 3, the moisture-curing polyurethane hot melt adhesives B to P, laminates B1 to P1, and moisture-permeable films B2 to P2.

[0142] [Evaluation methods for moisture permeability, normal state adhesive strength, water resistant adhesive strength, and hand feeling]

[0143] [Measurement method of moisture permeability of laminated body and moisture-permeable film]

[0144] Measurement was performed based on JIS L1099 (A-1: calcium chloride method).

[0145] A laminate and a moisture-permeable film having a moisture permeability of approximately 6,000 or more can be said to have practically sufficient moisture permeability.

[0146] [Measuring method of normal adhesive strength]

[0147] On the surface of the moisture-permeable polyurethane film 1 constituting each laminate, a 1-inch-wide hot-melt fabric tape (manufactured by Sun Chemical Co., Ltd.) was attached at 130...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com