Dinitrochlorobenzene synthesis method and microreactor

A technique for the synthesis of dinitrochlorobenzene and its synthesis method, which is applied in the field of synthesizing dinitrochlorobenzene from chlorobenzene, the synthesis method of dinitrochlorobenzene, and the field of microreactors. Consumption, Process Safety Continuity, Effects of Process Safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

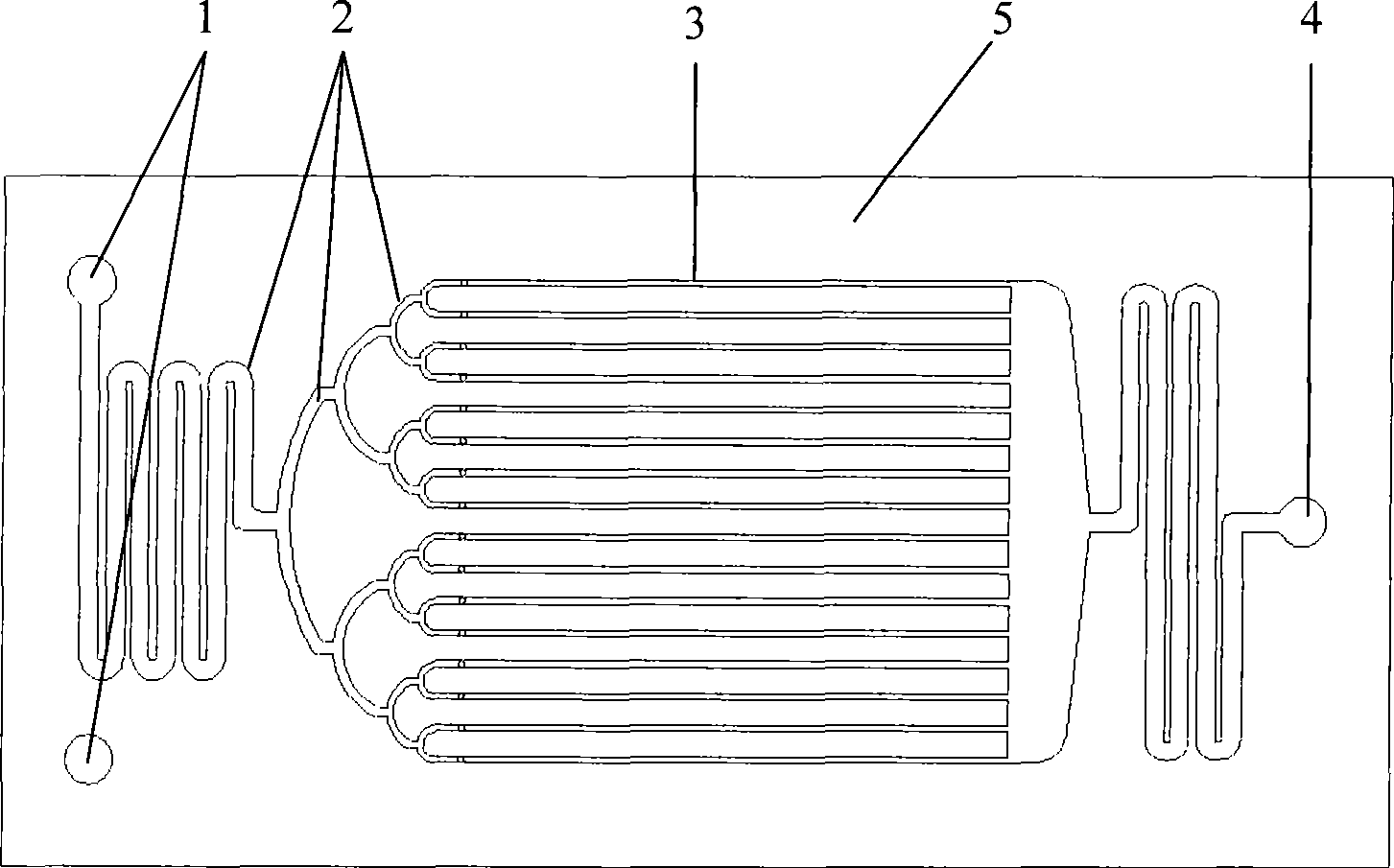

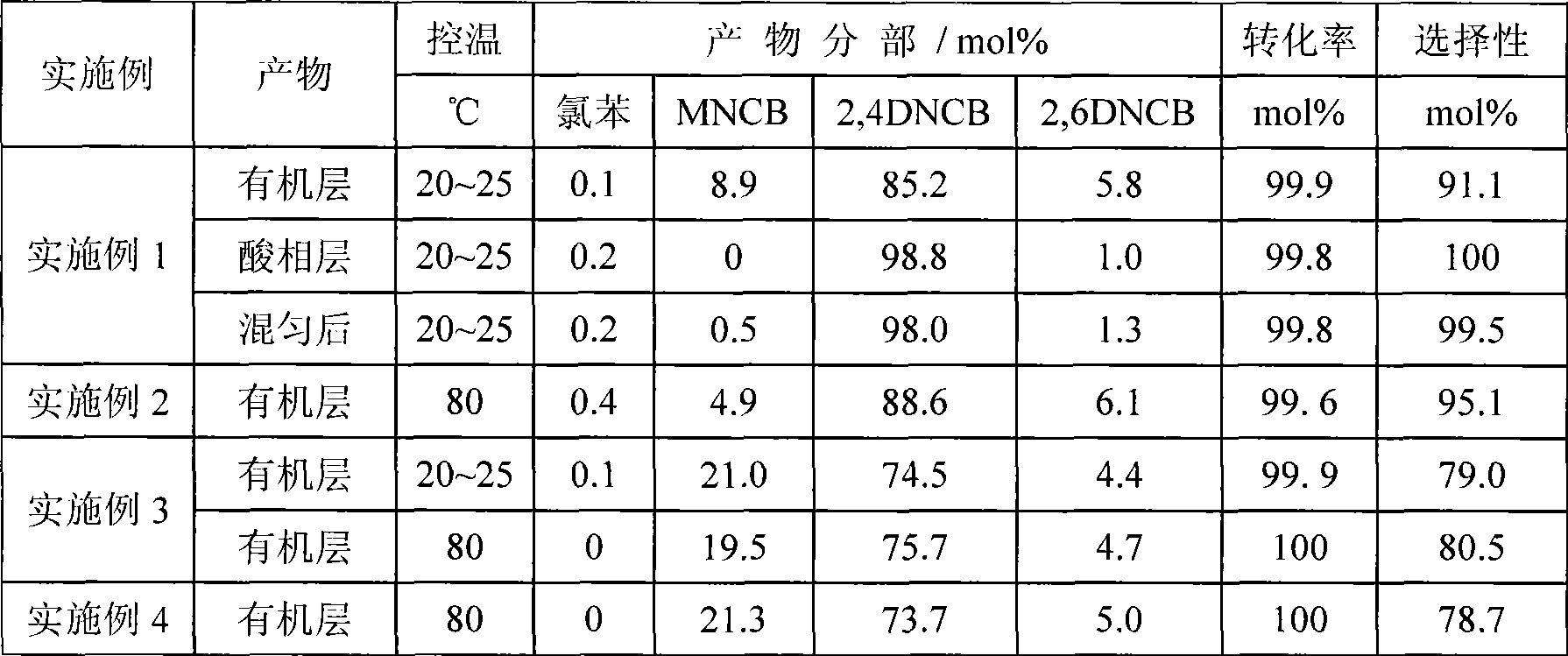

[0051] Use anhydrous nitric acid (≥98%) and concentrated sulfuric acid (≥95%) to prepare a mixed acid with an n / s value of 0.15±0.02 and a water concentration of 4±1%. During the preparation of mixed acid, the temperature is controlled below 35°C. Under normal temperature conditions, the mixed acid and chlorobenzene are continuously pumped into the microreactor (attached figure 1 The reactor shown) and react in the micro reaction channel. The mol ratio of this implementation reaction material nitric acid and chlorobenzene is 2.08, and the liquid hourly space velocity of reactor 1516h -1 . The reaction product flows out of the reactor continuously, and the temperature of the product flowing out of the reactor is 36°C, and it is placed in a separator for stratification, and the acid solution is separated, and the acid solution takes an appropriate amount of water (about 1 / 10 to 1 / 2 of the volume of the spent acid) 20) Dinitrochlorobenzene is reclaimed by dilution and melting ...

Embodiment 2

[0053] The process and mixed acid composition are the same as in Example 1, the temperature of the reactor is controlled at 80°C, the molar ratio of nitric acid to chlorobenzene is 2.22, and the liquid hourly space velocity of the reactor is 1485h -1 , the outlet temperature of the reactor product was 89°C, and only the composition of the organic layer of the product was analyzed.

Embodiment 3

[0055] The process is the same as in Example 1, the mixed acid n / s value is 0.30±0.02, water 4±1%, the reactor is controlled at normal temperature and 80°C respectively, the temperatures at the outlet of the reactor are respectively 31°C and 124°C, and the reaction material nitric acid The molar ratio of p-chlorobenzene is 1.94 and 2.10 respectively under two different temperature conditions, and the liquid hourly space velocity in the reactor is 1695h respectively -1 and 1656h -1 , only analyze the product composition in the product organic layer, table 1 shows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com