Fermented liquid pasty fertilizer and preparation method thereof

A biogas slurry and fertilizer technology, applied in the field of biogas slurry paste fertilizer and its preparation, can solve problems such as weak and invisible, and achieve the effects of reducing leaching loss, reducing dosage, and high absorption and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A biogas slurry paste fertilizer, which consists of the following components:

[0046] Biogas slurry 35kg Urea 8kg Diammonium phosphate 8kg

[0047] Potassium sulfate 10kg Ammonified lignite 32kg Biogas microbial agent 2kg

[0048]Indole acetic acid 0.1kg Ferrous ethylenediamine tetraacetate 0.7kg

[0049] Citric acid 0.7kg Carboxymethylcellulose sodium 0.5kg Bentonite 3kg

[0050] Polyglycerin fatty acid ester 0.3kg.

[0051] A preparation method of biogas slurry paste fertilizer, the steps are as follows:

[0052] 1) Take weathered lignite and add ammonium bicarbonate in a ratio of 14.7%, make it ammoniate in a reaction kettle at a temperature of 20-30° C. for 24 hours to obtain ammoniated lignite;

[0053] 2) Take the biogas slurry that has been anaerobically fermented for 50 to 60 days using chicken manure as raw material, filter out the biogas residue through a filter press, take the liquid, add carboxymethyl cellulose sodium to the above liquid, and stir evenl...

Embodiment 2

[0076] Biogas slurry paste fertilizer as described in embodiment 1, the difference is that,

[0077] Biogas slurry 30kg Urea 15kg Diammonium phosphate 10kg

[0078] Potassium sulfate 10kg Ammonified lignite 30kg Indole acetic acid 0.2kg

[0079] Polyglyceryl fatty acid ester 0.5g Sodium carboxymethyl cellulose 0.5kg Bentonite 2.8kg.

[0080] The preparation method is the same as in Example 1.

[0081] Application method:

[0082] Mix the paste fertilizer with water at a weight ratio of 1:10 to form a slurry, and apply it together with crop irrigation.

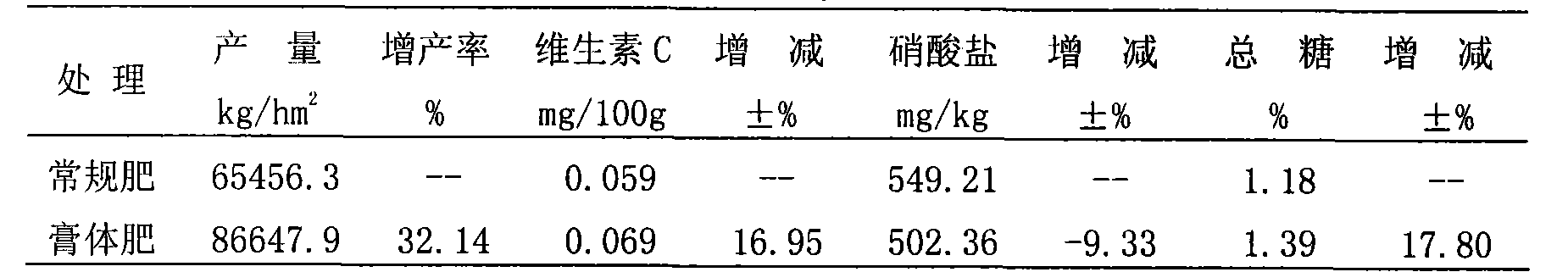

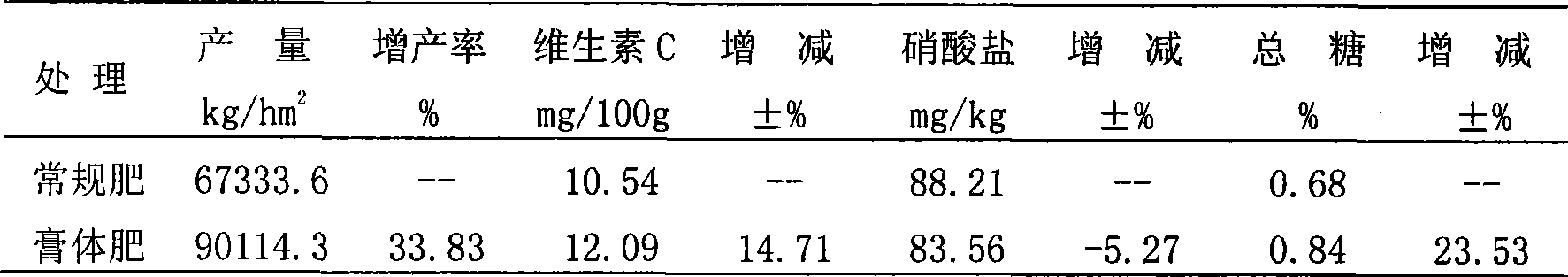

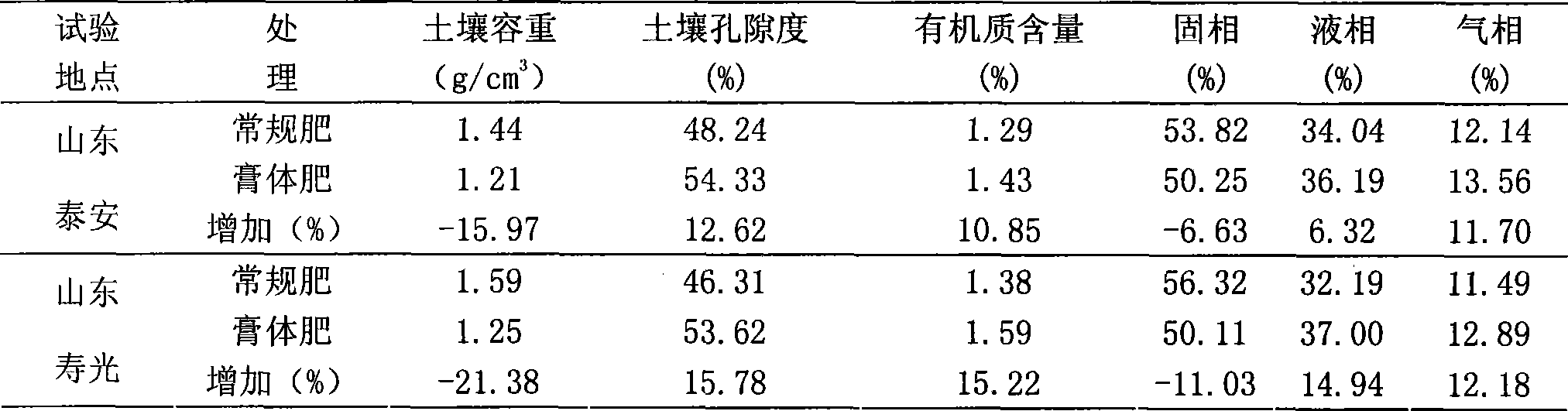

[0083] Application effect:

[0084] The fertilizer was tested on peach trees in Daqiao Village, Xincheng Town, Feicheng City. Treatment 1 was the routine fertilization of farmers as the control group, and the conventional fertilizer was 450kg / hm of nitrogen fertilizer. 2 , Phosphate fertilizer 600kg / hm 2 , potash fertilizer 1000kg / hm 2 Paste fertilizer is to use the biogas slurry paste fertilizer of the present invention...

Embodiment 3

[0089] Biogas slurry paste fertilizer as described in embodiment 1, the difference is that,

[0090] Biogas slurry 35kg Urea 10kg Diammonium phosphate 10kg

[0091] Potassium sulfate 10kg Ammonified lignite 30kg Indole acetic acid 0.2kg

[0092] Polyglyceryl fatty acid ester 0.5g Sodium carboxymethyl cellulose 0.5kg Bentonite 3.8kg.

[0093] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com