Method for inhibiting expansion of fluidized bed combustion coal ash/slag products

A technology for sulfur-fixing ash and products, which is applied to chemical instruments and methods, manufacturing tools, clay preparation devices, etc., and can solve the problems of poor adaptability between accelerators and sulfur-fixing ash, complex changes in the composition of sulfur-fixing ash, and cement To solve the problem of high clinker content, achieve the effect of improving volume stability, good suppression effect and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

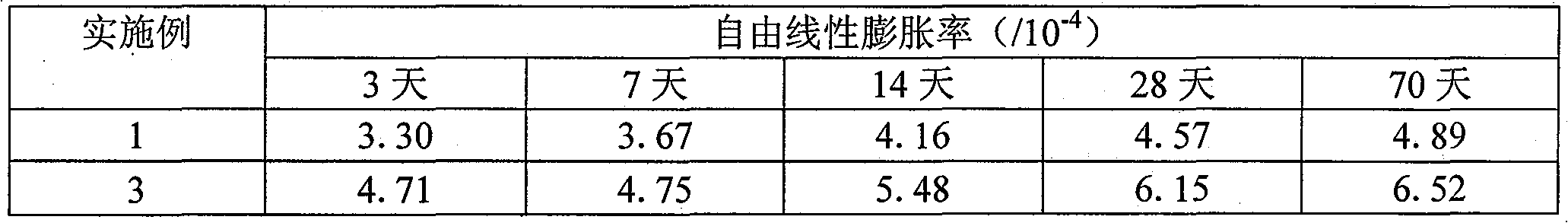

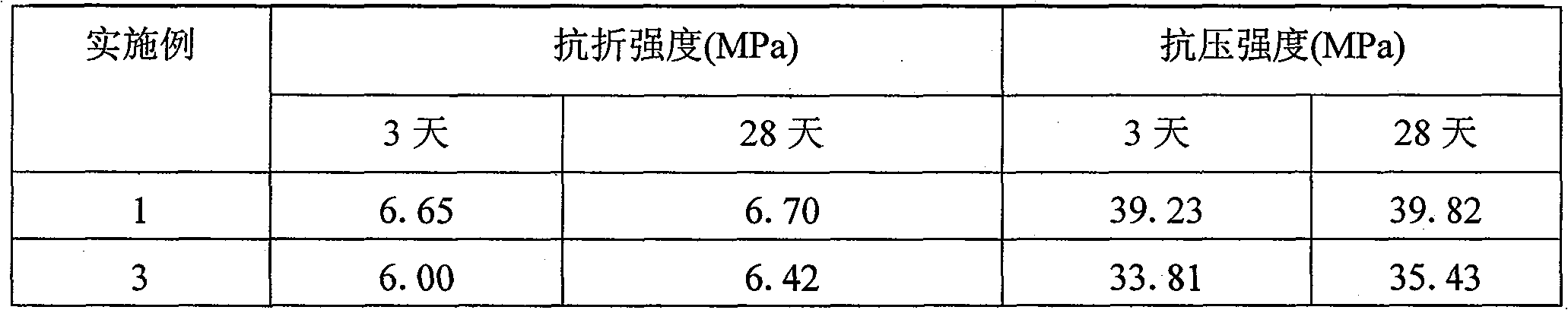

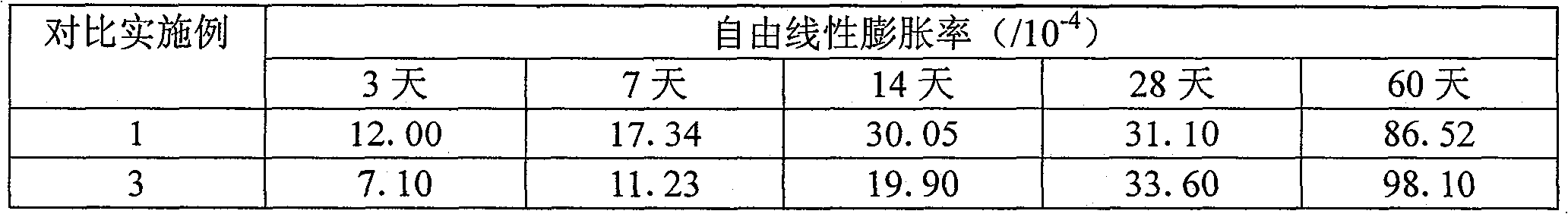

Examples

Embodiment 1

[0025] The specific steps of a method for suppressing the expansion of sulfur-fixed ash products are as follows:

[0026] (1) Preparation of raw materials

[0027] The sulfur-fixing slag discharged from the fluidized bed boiler coal-fired power plant and the cement clinker produced by the cement plant are respectively ground by grinding equipment (ie, a ball mill) to a fineness of 180 mesh (screen residue <10%) and then used for later use. The cement produced by the cement plant and the undisturbed sulfur-fixed ash discharged from the fluidized bed boiler coal-fired power plant are directly used.

[0028] (2) Molding of sulfur-fixed ash products

[0029] After (1) step is finished, take sulfur-fixing ash powder and cement clinker powder and cement as the raw material of cementing material, press sulfur-fixing ash powder: cement clinker powder: the ratio of the mass percent of cement is 75%: In the ratio of 25%:0%, sand is first added to the cementing material, and then mixin...

Embodiment 2

[0033] The specific steps of a method for suppressing the expansion of sulfur-fixed ash products are as follows:

[0034] (1) Preparation of raw materials

[0035] With embodiment 1.

[0036] (2) Molding of sulfur-fixed ash products

[0037] With embodiment 1, feature is: sulfur-fixing ash powder: cement clinker powder: the mass percent of cement is 100%: 0%: 0%, cementing material: the mass ratio of sand is 1: 2.0, adopts pouring molding, cementation The mass ratio of materials: mixing water is 1:0.7.

[0038] (3) autoclave curing

[0039] With embodiment 1, feature is: pressure rises to 1.7 MPa, boosting time is 4 hours, constant pressure steaming time is 2 hours, and decompression time is 4 hours.

Embodiment 3

[0041] The specific steps of a method for suppressing the expansion of sulfur-fixed ash products are as follows:

[0042] (1) Preparation of raw materials

[0043] With embodiment 1, the feature is: the grinding equipment is a vibration mill.

[0044] (2) Molding of sulfur-fixed ash products

[0045]With embodiment 1, the feature is: sulfur-fixing ash powder: cement clinker powder: the mass percent of cement is 75%: 0%: 25%, cementing material: the mass ratio of sand is 1: 3.0, adopts pouring molding, cementation The mass ratio of materials: mixing water is 1:0.4.

[0046] (3) autoclave curing

[0047] With embodiment 1, feature is: the pressure rises to 1.5 MPa, and the pressurization time is 3 hours, and the constant pressure steaming time is 6 hours, and the depressurization time is 3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com