Closed self-circulation hydraulic pipeline flusher

A technology of flushing device and hydraulic pipeline, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc. The effect of reducing the amount of oil used for circulating flushing, improving flushing efficiency, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

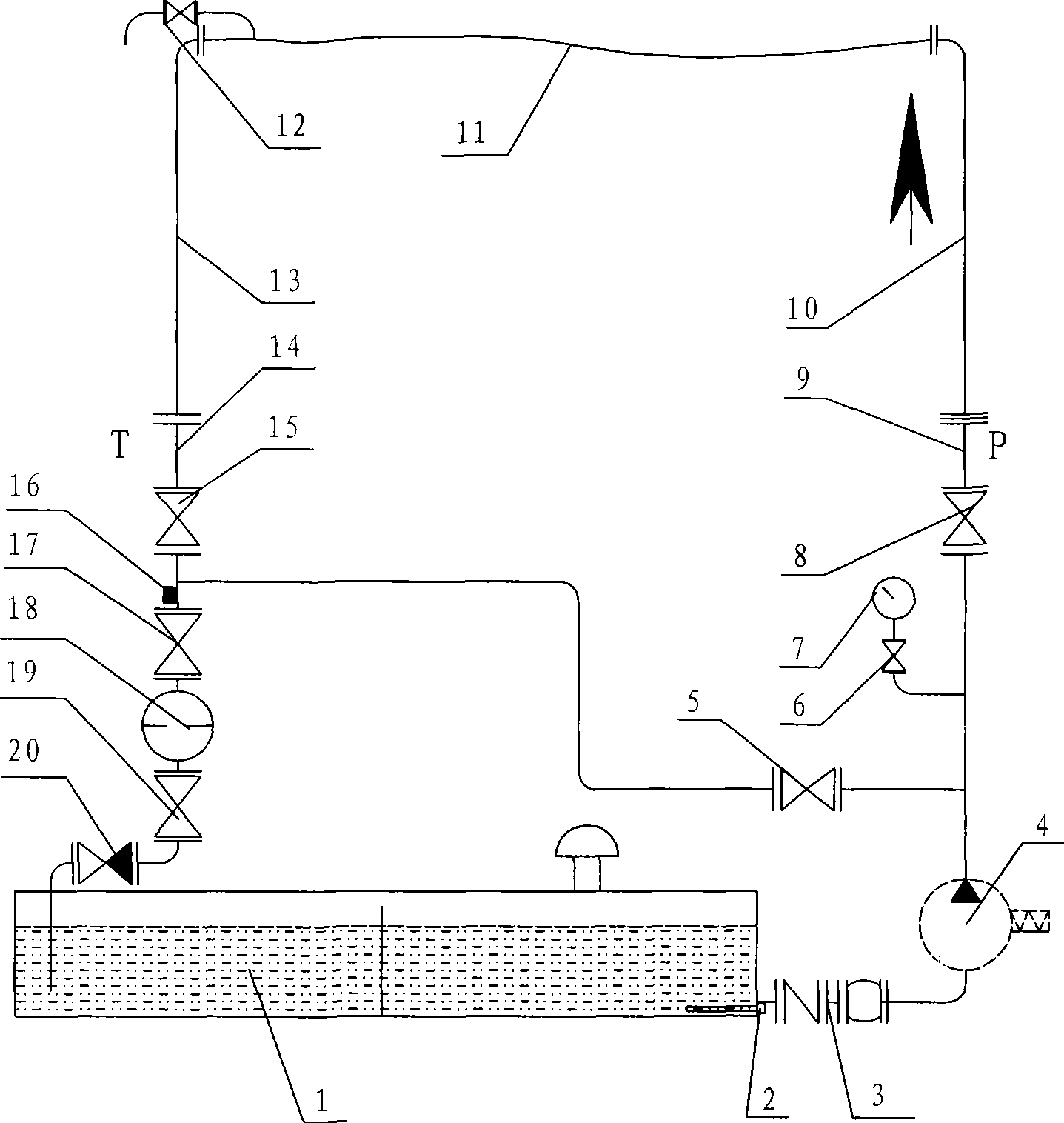

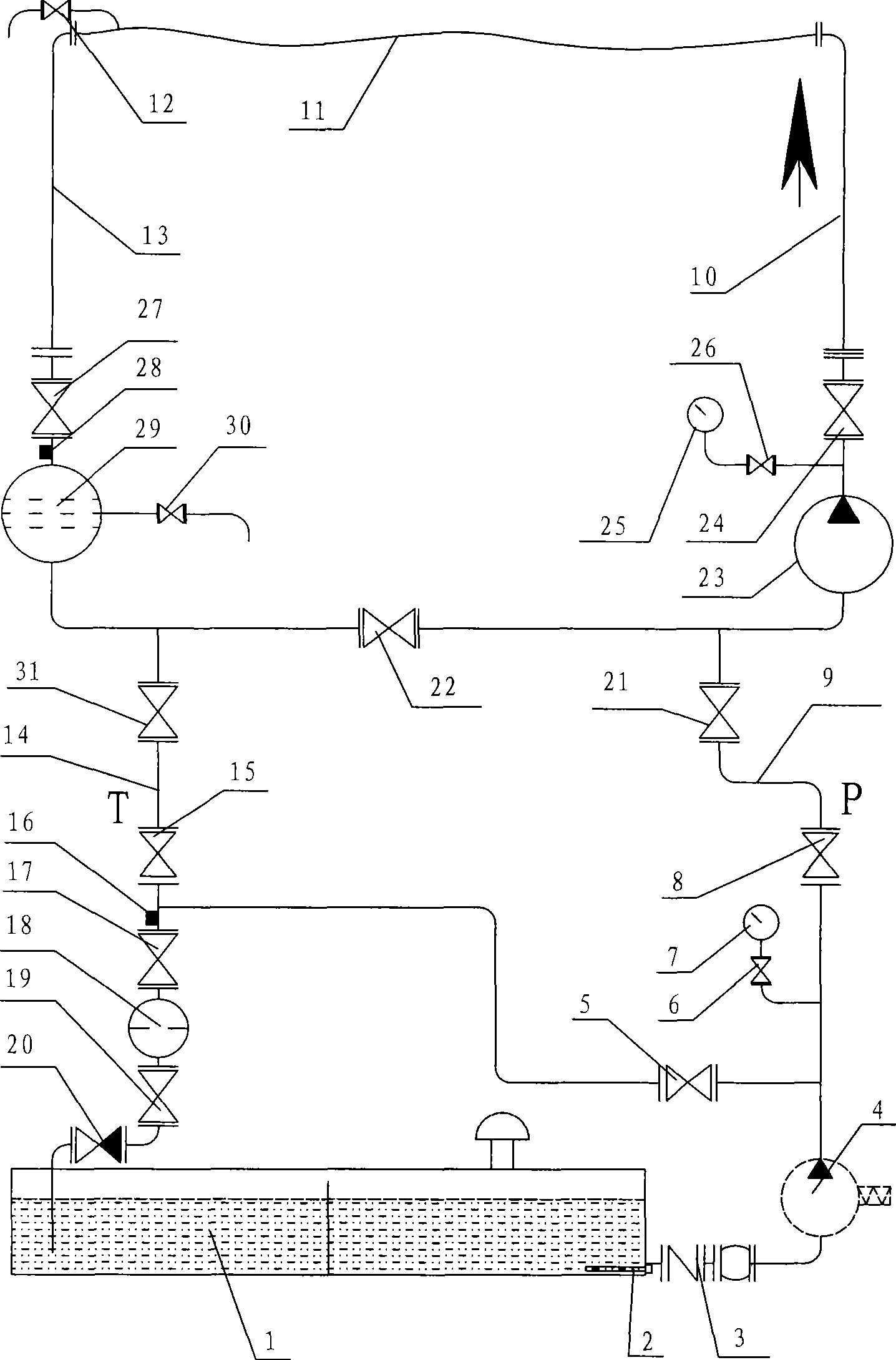

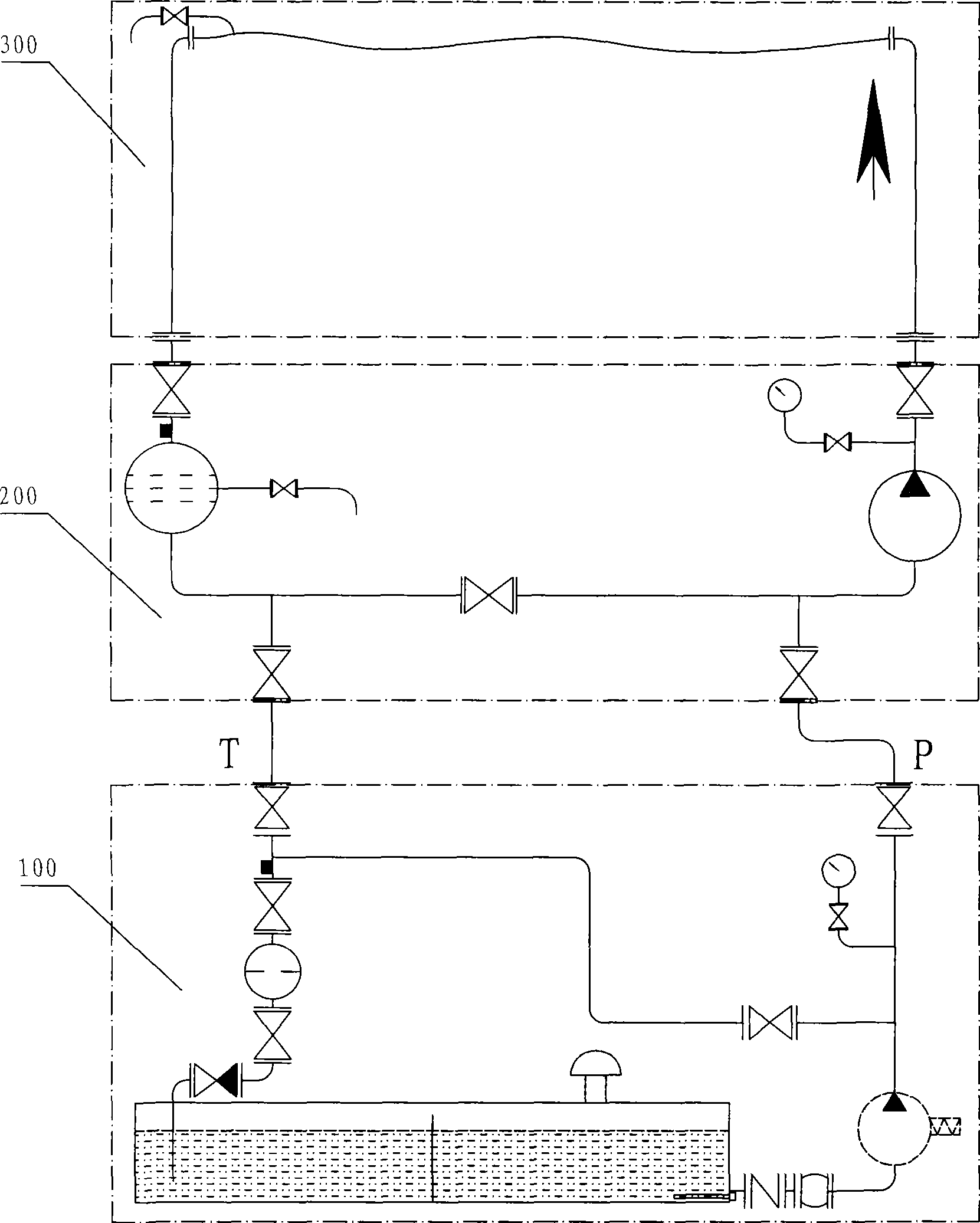

[0021] The invention will be further described below in conjunction with the accompanying drawings with specific embodiments:

[0022] Because the oil in the traditional open oil circulation flushing system returns to the oil tank 1 through the oil return pipe, the oil flows in an open manner and is easy to contact with the atmosphere to generate a large number of air bubbles. To guarantee the normal operation of the oil pump 4, these air bubbles must be eliminated, and to eliminate these air bubbles, it is necessary to keep the oil to stand still for a period of time and keep the liquid level to a certain depth. Like this, adopt the circulation flushing pumping station of large-flow high-pressure pump, its oil tank 1 must be huge. Such as figure 2 As shown, a closed self-circulating hydraulic pipeline flushing device according to the present invention includes three parts: an oil-filled pumping station 100, a self-circulating flushing device 200 and a flushing pipeline 300....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com