Cat litter and preparing method thereof

A cat litter and core technology, applied in the field of its production method, can solve the problems of high cost and large amount of raw material bentonite, and achieve the effects of high production efficiency, reduced product dust and easy cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

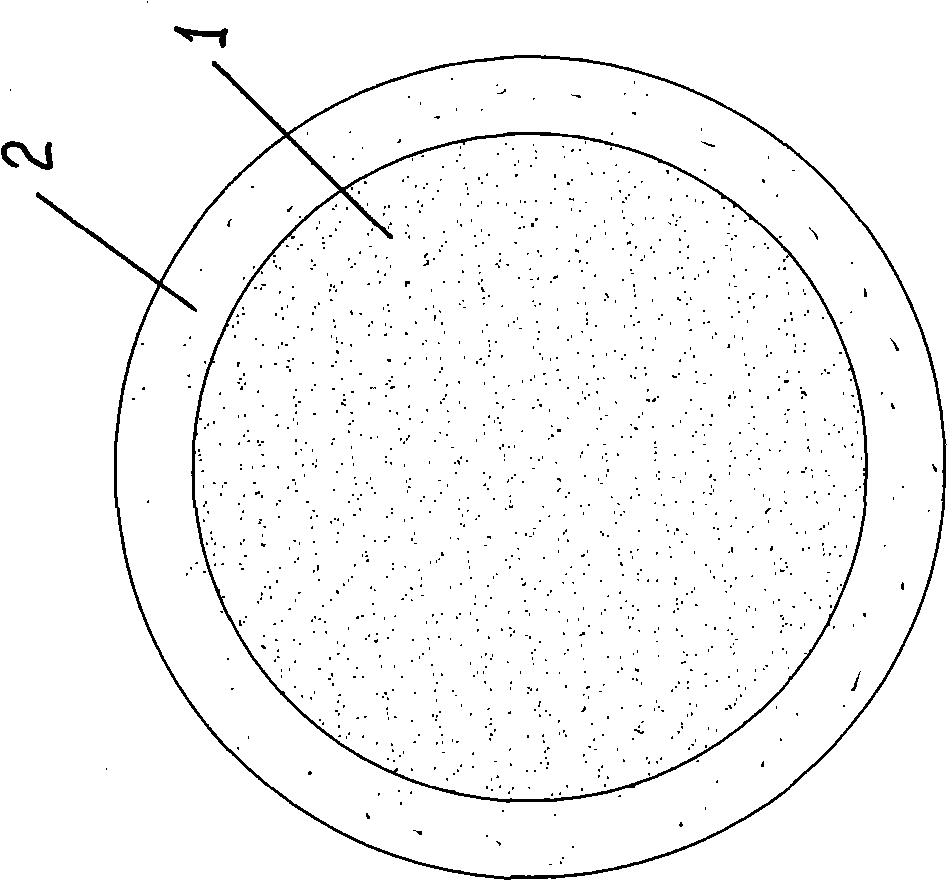

[0025] a cat litter, such as figure 1 As shown, it is the clay layer 2 bonded to the inner core 1, and the inner core 1 is made of perlite or pumice.

[0026] The first step of ingredients: take the inner core perlite or pumice, clay montmorillonite according to the measurement, measure the montmorillonite and water according to the weight ratio of 25:100, mix and stir evenly to make clay slurry for later use;

[0027] The second step of slurrying: put the inner core in a mixing tank, add clay slurry, the weight ratio of the inner core to the clay slurry is 30:40, and mix evenly to obtain the inner core of the clay slurry layer;

[0028] The third step: drying, drying the inner core product of the clay slurry layer at a temperature of 150° C. for 1 minute until the moisture content is less than 6% to obtain cat litter.

Embodiment 2

[0030] The first step of ingredients: take the inner core perlite, clay bentonite and fiber paper powder according to the measurement, measure the bentonite and water according to the weight ratio of 30:100, mix and stir evenly to make clay slurry for later use; weigh according to the weight ratio of 100:2 Bentonite and paper powder are mixed evenly to make mixed soil for subsequent use;

[0031] The second step of slurrying: put the perlite in the mixing tank, add clay slurry, the weight ratio of perlite and clay slurry is 40:40, mix for about 1 minute until uniform, and make the clay slurry layer perlite;

[0032] The third step is to hang the mixed soil: the slurry perlite and the mixed soil are measured according to the weight ratio of 55:50, and 55 parts of the clay slurry layer perlite are added to 40 parts of the mixed soil for granulation, and the surface of the mixed soil oozes out water and then Add the remaining 10 parts of mixed soil, the surface of the whole mixed...

Embodiment 3

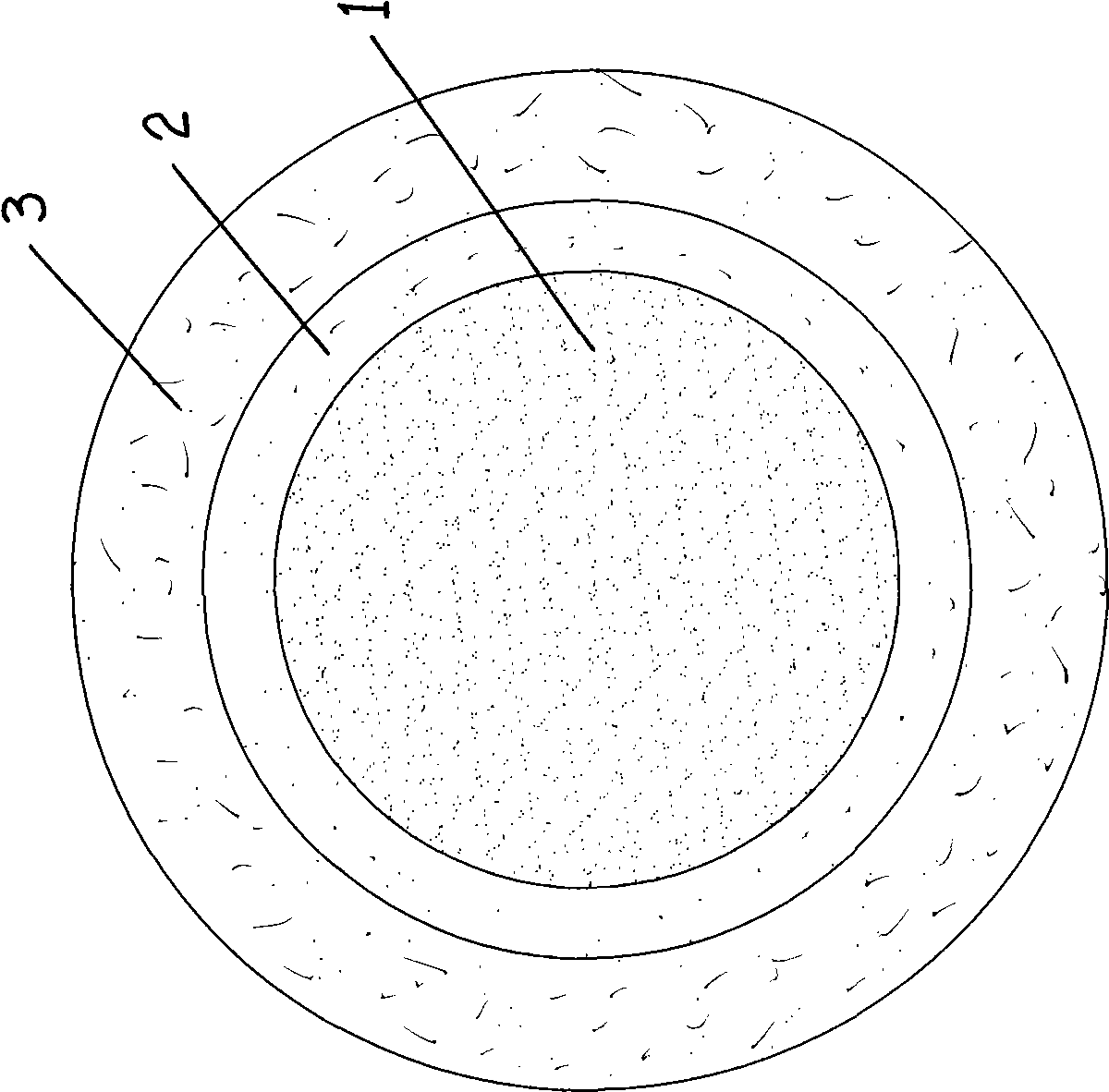

[0036] Prepare as described in Example 2 figure 2 The cat litter shown is different in that the raw materials used are as follows:

[0037] The first step of ingredients: mix bentonite and water at a weight ratio of 35:100 to make clay slurry for later use; weigh bentonite and lignin fiber at a weight ratio of 100:1 to make mixed soil;

[0038] The second step of hanging slurry: the weight ratio of perlite and clay slurry is 30:40 to prepare perlite in hanging clay slurry layer;

[0039] The third step is to hang the mixed soil: the weight ratio of the slurry perlite to the mixed soil is 60:50, the first granulation is 60 parts of the clay slurry layer perlite and 35 parts of the mixed soil, and the second granulation is added with 15 parts of the mixed soil ;

[0040] The fourth step is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com