Recognition mark, and circuit substrate manufacturing method

A technology of identification marks and manufacturing methods, applied in the field of identification marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

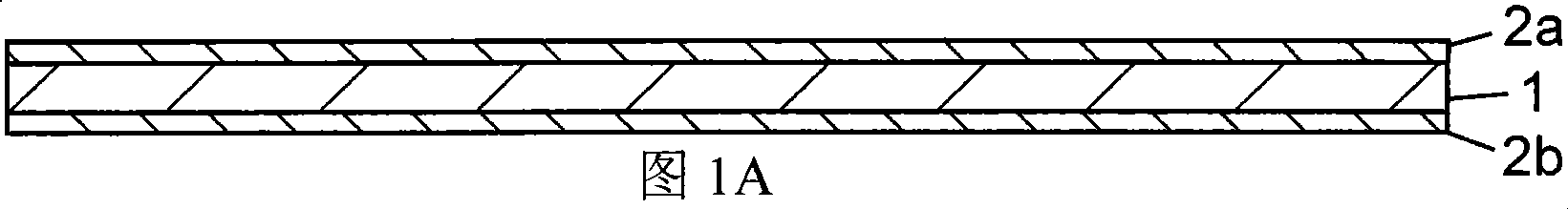

[0122] first as Figure 1A As shown, the release films 2a, 2b are attached to the front and back surfaces of the prepreg 1 using a laminating device.

[0123] The prepreg 1 uses a base material formed of a composite material such as wholly aromatic polyamide fiber or glass fiber cloth of a nonwoven fabric impregnated with a thermosetting epoxy resin. A laminating device is used to bond a plastic film having a release layer portion formed on the front and back surfaces of the prepreg 1 , for example, release films 2 a , 2 b made of polyethylene terephthalate or the like.

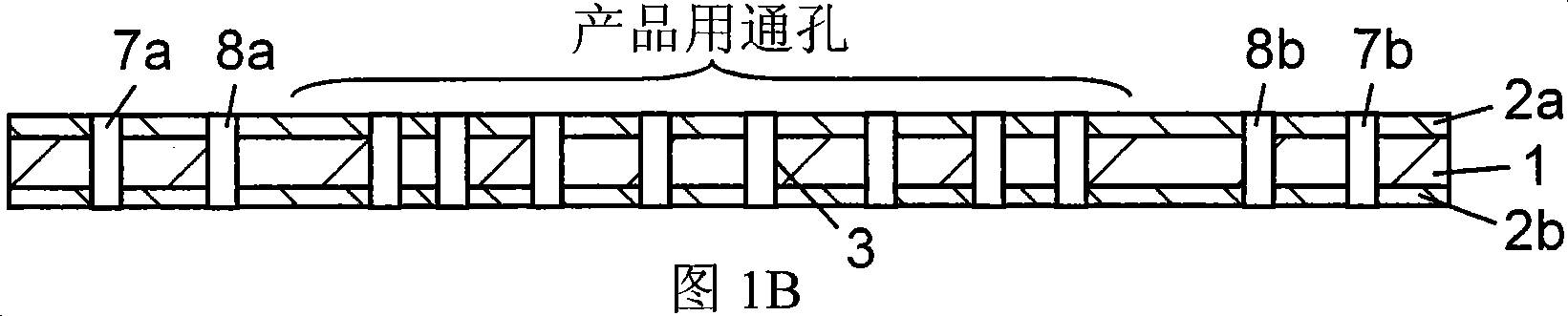

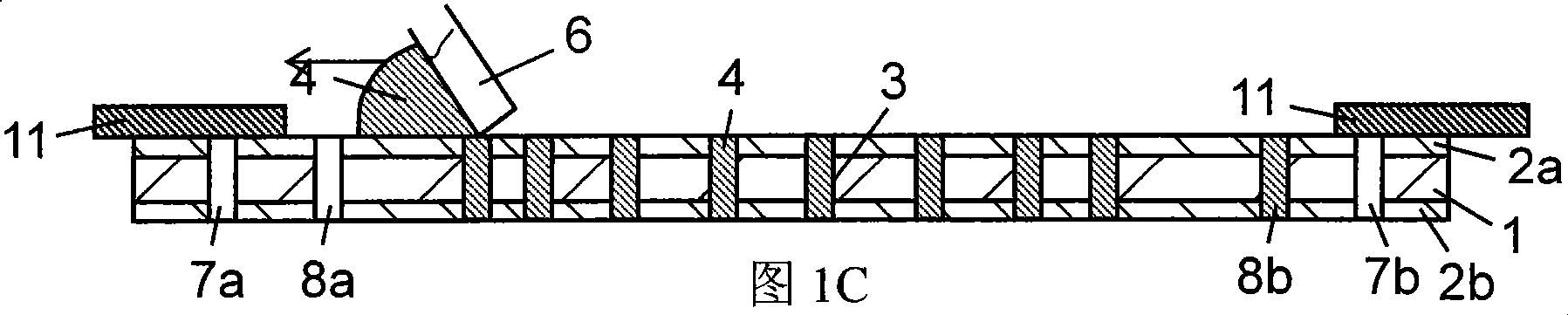

[0124] Secondly, if Figure 1B As shown, via holes 3 serving as internal via holes are formed by laser processing or the like. At this time, while forming the via hole 3 for the product (that is, for interlayer connection), the via hole 7a, 7b for the lamination identification mark not filled with the conductive paste 4 described below is formed by laser processing, and the via hole 7b for the thermal press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com