Method for preparing surface enhanced Raman scattering optical fiber probe

A surface-enhanced Raman and fiber optic probe technology, which is applied in Raman scattering, material excitation analysis, etc., can solve the problems of high operational difficulty, poisonous and harmful corrosive liquid, and difficulty in accurately controlling the corrosion morphology of the end face of the optical fiber. Simple, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Silver nitrate solution (1 mM) and sodium citrate solution (1 mM) were mixed, and 100 μL of the mixed solution was taken as reaction solution 4.

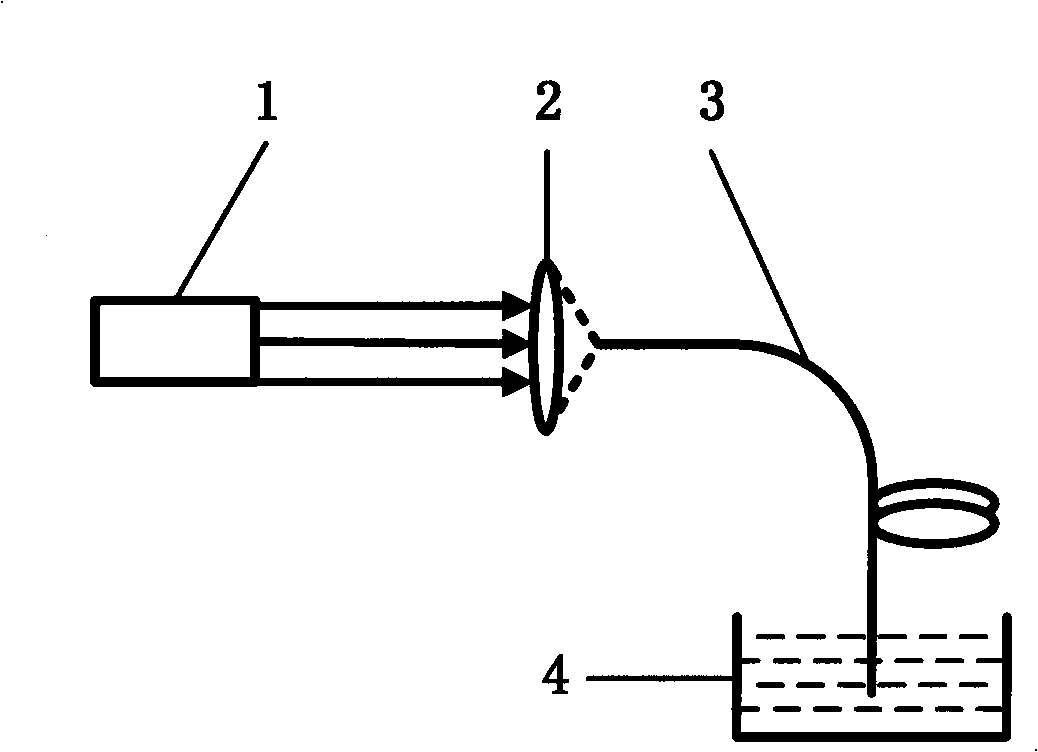

[0028] (2) Refer to figure 1 , the laser light source 1 is a helium-neon laser, and the central wavelength of the output laser is 632.8nm. Optical fiber 3 is a standard single-mode optical fiber with a cladding diameter of 125 μm and a core diameter of 9 μm. Both ends of the optical fiber are cut to be perpendicular to the axis of the optical fiber. The laser light output from the laser light source 1 is coupled into the near end of the optical fiber 3 through the converging lens 2, and the laser light propagates in the optical fiber according to the fundamental mode, and the output power from the far end of the optical fiber 3 is 4.25mW.

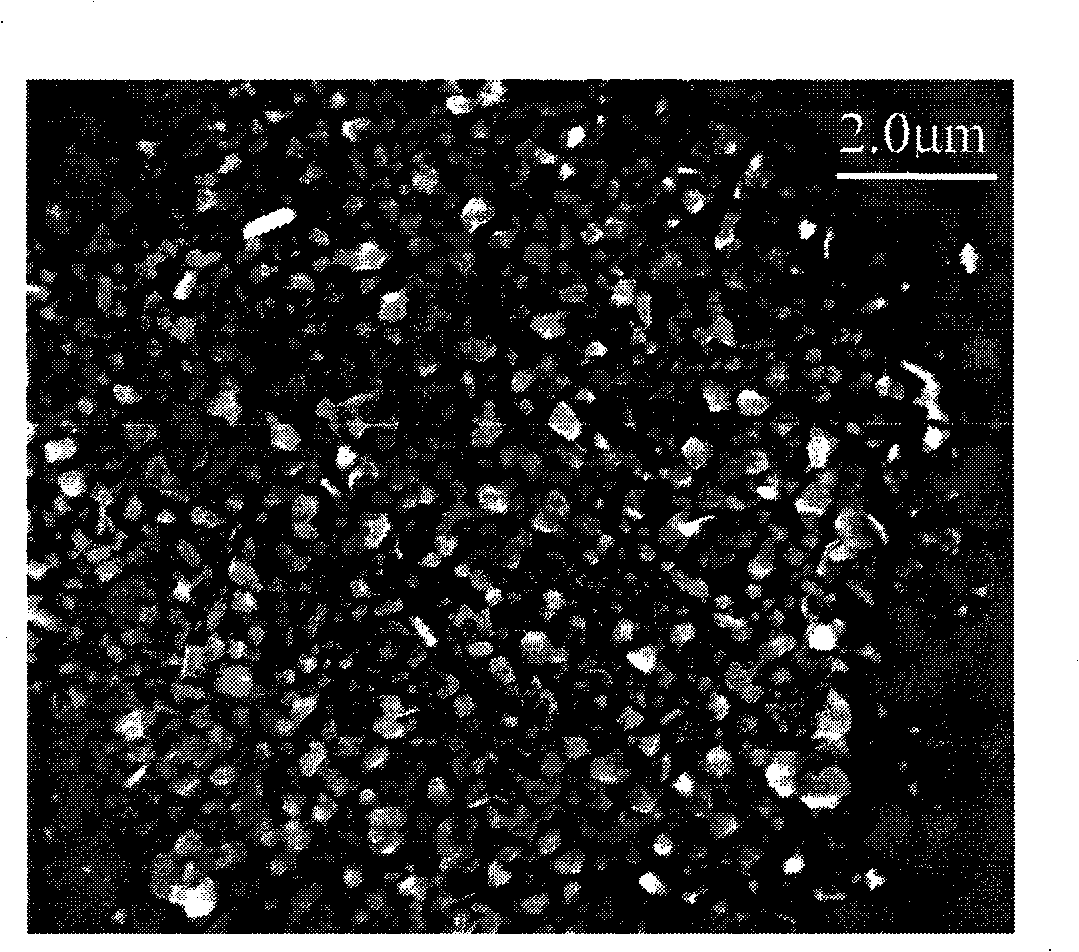

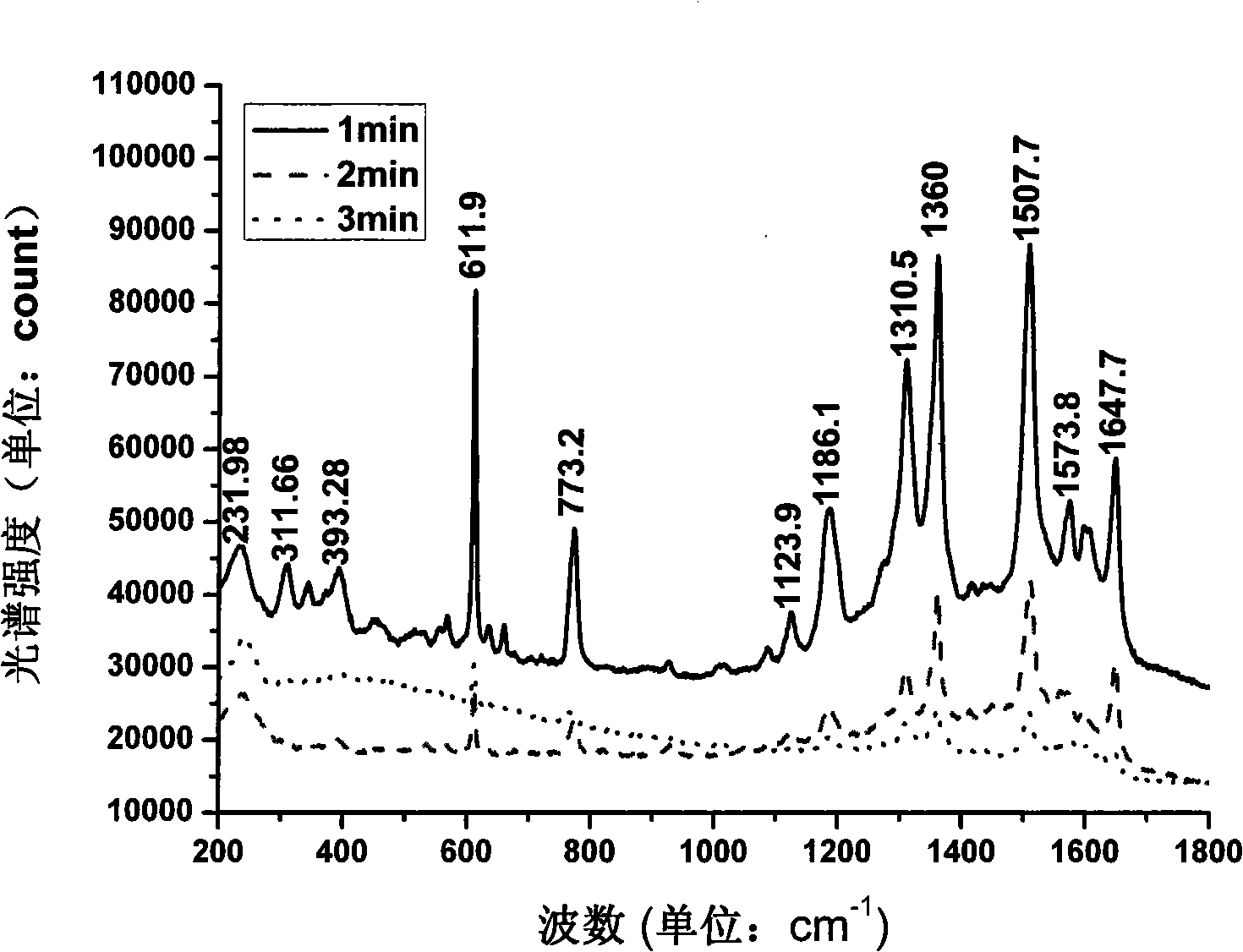

[0029] (3) The distal end of the optical fiber 3 is immersed in the reaction solution 4 . After 3 minutes of laser irradiation, the silver ions in the reaction solution were reduced ...

Embodiment 2

[0032] Example 2: Silver nitrate solution (0.1 mM) and sodium citrate solution (1 mM) were mixed, the output power of the laser at the far end of the optical fiber 3 was 6.00 mW, and the rest of the reaction conditions were referred to in Example 1. After 10 minutes of laser irradiation, silver nanoparticle deposition was formed on the core region of the far end of the fiber, thereby obtaining a surface-enhanced Raman scattering fiber probe.

Embodiment 3

[0033] Example 3: Silver nitrate solution (2mM) and sodium citrate solution (1mM) were mixed, the output power of the laser at the far end of the optical fiber 3 was 6.00mW, and the rest of the reaction conditions were referred to in Example 1. After irradiating the laser for 1 min, silver nanoparticle deposition was formed on the core region of the far end face of the fiber, thereby obtaining a surface-enhanced Raman scattering fiber probe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com