An inclined-axis hydraulic plunger pump or motor

A hydraulic plunger pump and plunger technology, which is applied in the direction of pumps, multi-cylinder pumps, liquid variable capacity machines, etc., can solve the problems of unsatisfactory damping effect, difficulty, increased maintenance costs, etc., to achieve satisfactory damping effect, reduce Difficulty, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

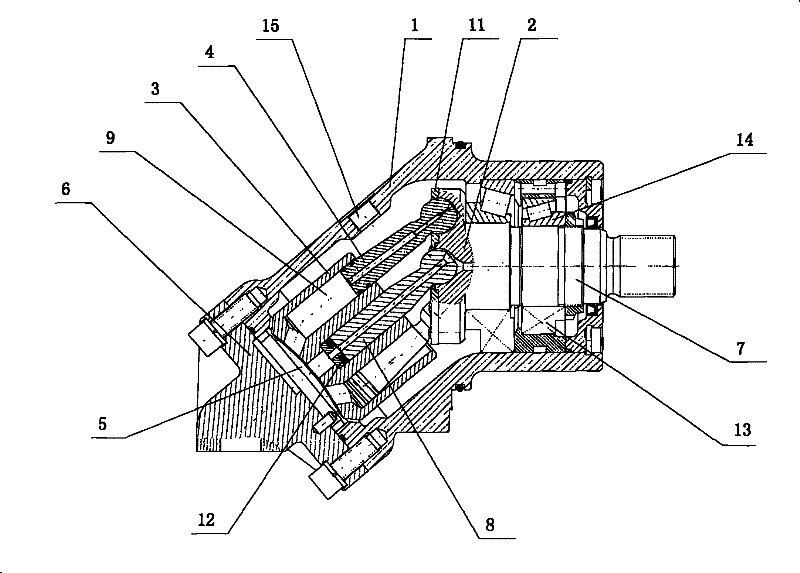

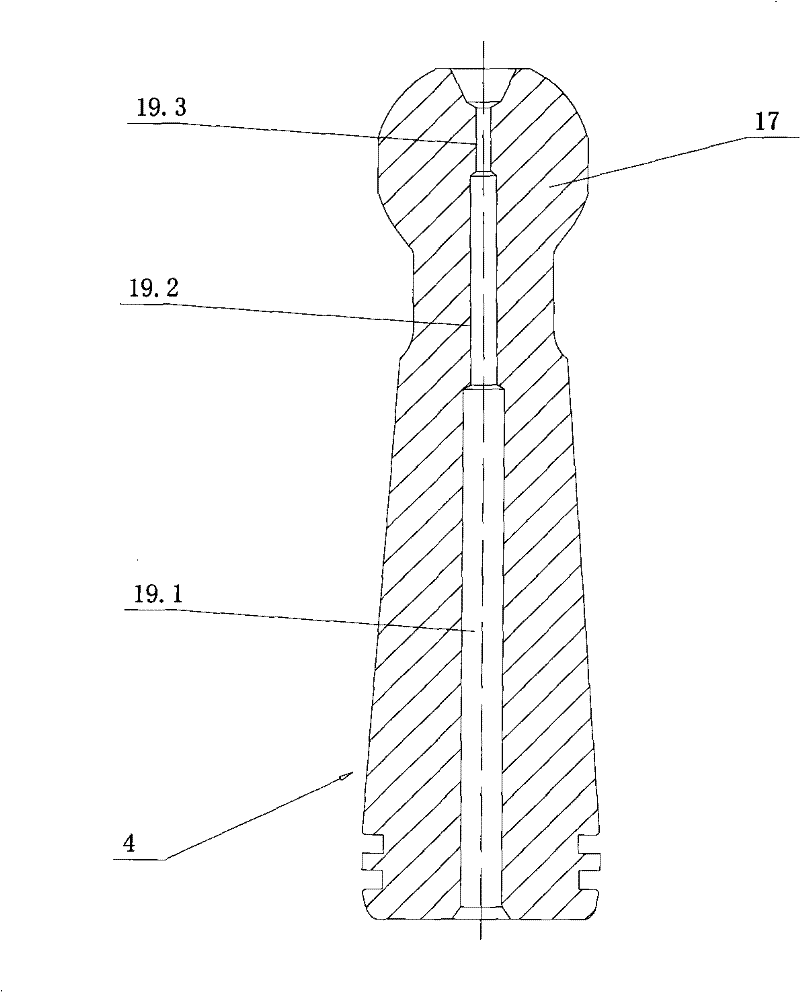

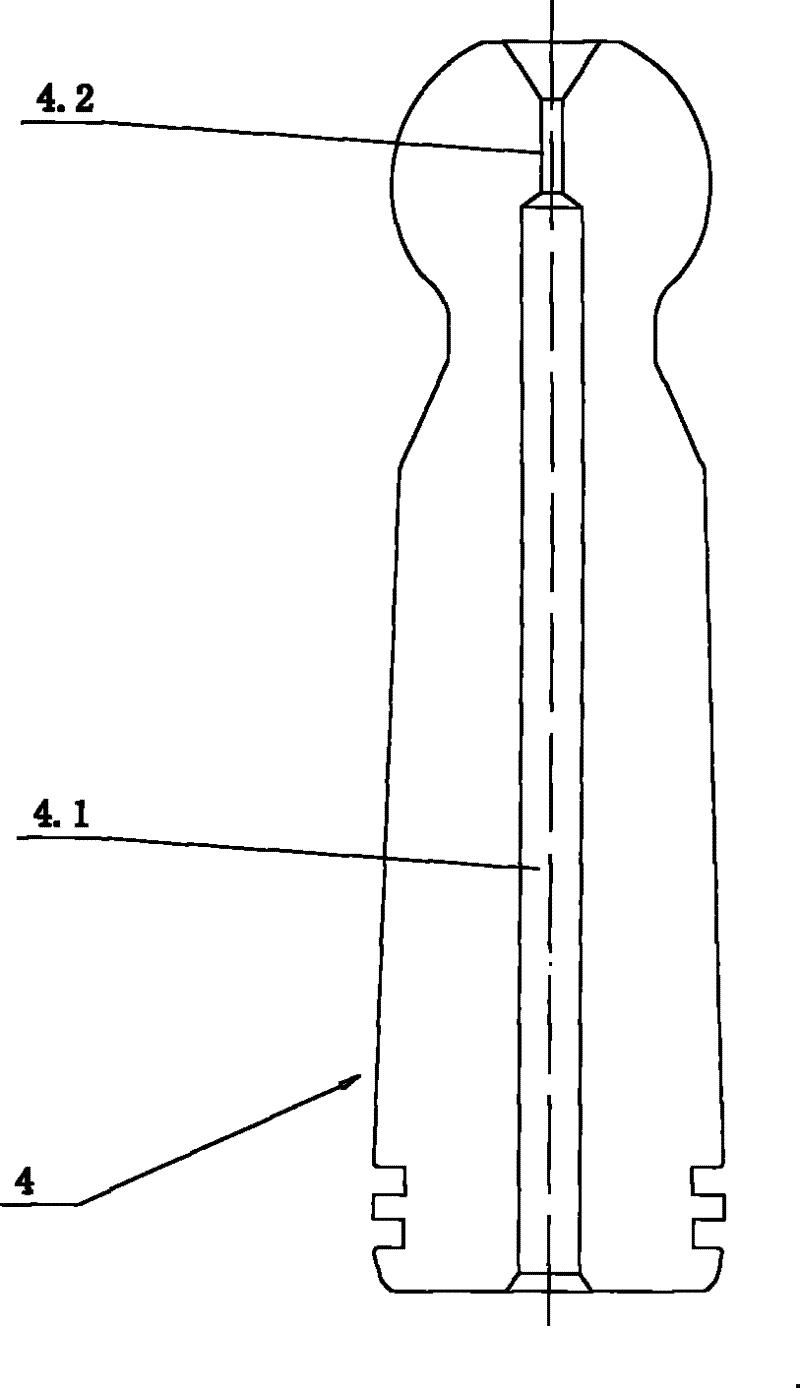

[0015] see figure 1 , Inclined axis hydraulic plunger pump or motor consists of a sealed working volume composed of housing 1, plunger connection plate 2, cylinder body 3, plunger 4, flow distribution plate 5 and pump cover 6, plunger connection plate 2 and drive shaft 7 is made into one body and installed on the ball bearing 13 and the cone bearing 14 in the housing 1. The plunger connection plate 2 has an inclination angle with the central plunger 8, and seven plungers 4 are arranged in the plunger hole 9 of the cylinder body 3, and the ball head of the plunger 4 matches the ball socket on the plunger connection plate 2, and passes through The return disc 11 is coupled with the plunger connection disc 2 . A central plunger 8 is installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com