Al-Sb-Y-Mg modifier for hypoeutectic Al-Si alloy and preparation process thereof

A modification agent and hypoeutectic technology, applied in the field of aluminum alloy application, can solve the problems of small domestic production, large hydrogen absorption capacity of aluminum alloy melt, and few resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

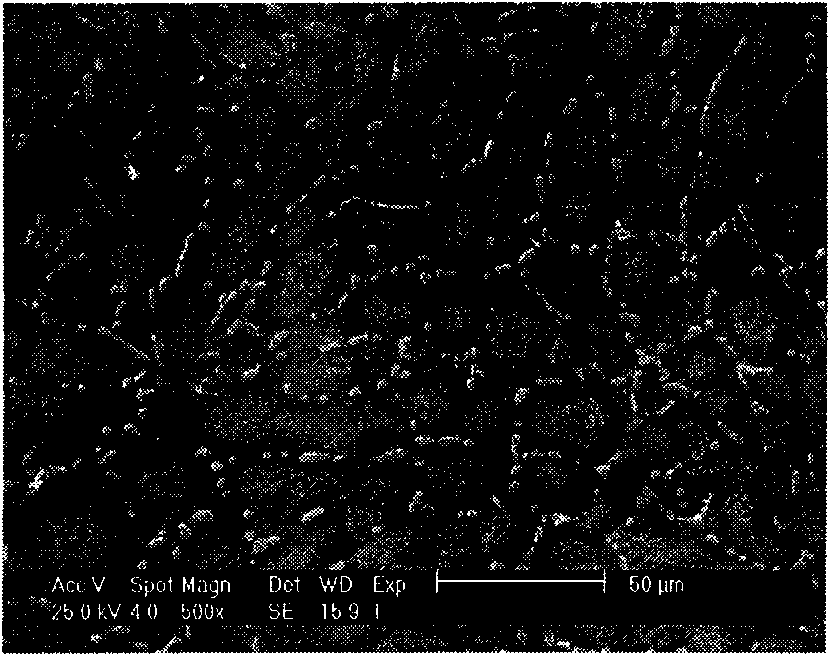

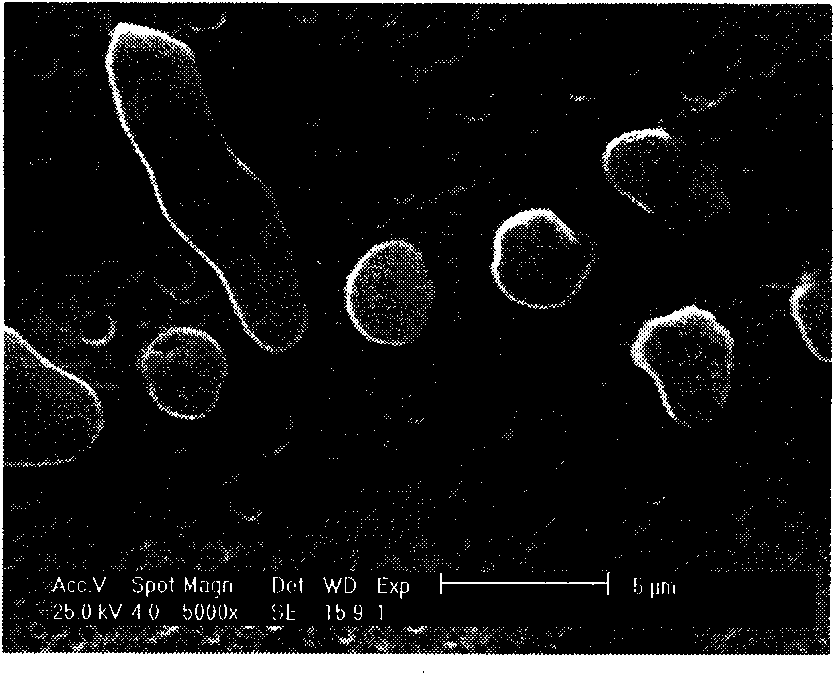

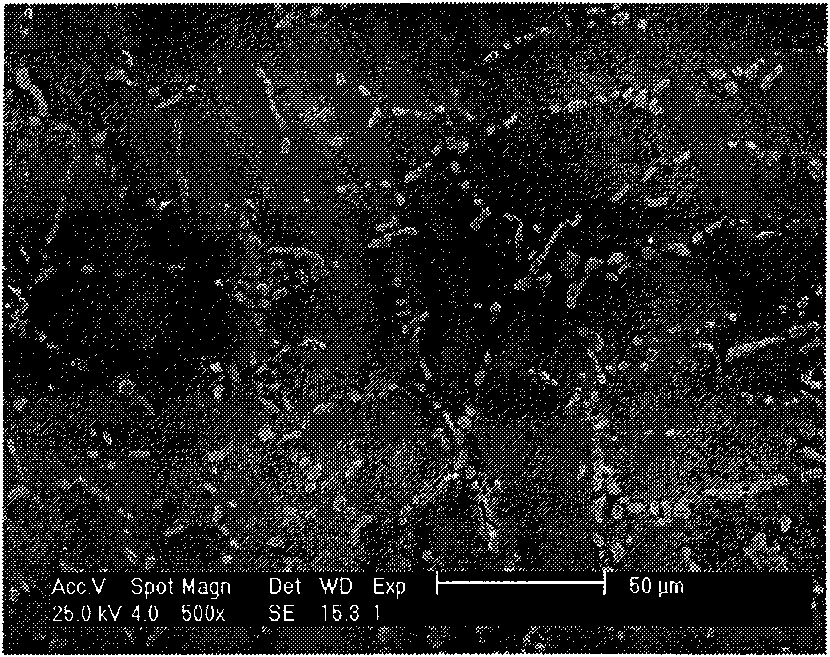

Image

Examples

Embodiment 1

[0020] The first step, prepare Al-Sb-Y-Mg modifier

[0021] The element composition of the modificator is designed in terms of weight percentage as Al: 82%, Sb: 15%, Y: 1%, Mg: 2%.

[0022] Prepare raw materials such as aluminum ingots, antimony ingots, yttrium ingots, and magnesium ingots according to the pre-designed modifier composition; place the graphite crucible in the resistance furnace and heat up the resistance furnace to 550°C, which will account for 82% of the weight percentage of the modifier. The ingot is put into a graphite crucible, and a layer of dry aluminum covering agent accounting for 1% by weight of the modificator is scattered on it; then the resistance furnace is heated to 760 ° C, and after the aluminum ingot is completely melted, the antimony ingot, yttrium ingot and magnesium ingots were successively added to the molten aluminum, wherein the additions of antimony ingots, yttrium ingots, and magnesium ingots accounted for 15%, 1%, and 2% of the weight ...

Embodiment 2

[0026] The first step, prepare Al-Sb-Y-Mg modifier

[0027] The element composition of the modificator is designed in terms of weight percentage as Al: 87%, Sb: 10%, Y: 2%, Mg: 1%.

[0028] Raw materials such as aluminum ingots, antimony ingots, yttrium ingots, and magnesium ingots are prepared according to the pre-designed modifier composition; the graphite crucible is placed in the resistance furnace and when the resistance furnace is heated to 500 ° C, 87% of the weight percentage of the modifier will be accounted for. The ingot was put into a graphite crucible, and a layer of dry aluminum covering agent accounting for 1.5% by weight of the modificator was scattered on it; , magnesium ingots were successively added to the molten aluminum, wherein the additions of antimony ingots, yttrium ingots, and magnesium ingots accounted for 10%, 2%, and 1% of the weight percentage of the modifier respectively, and were kept for 20 minutes. During the heat preservation process, high-pu...

Embodiment 3

[0033] The first step, prepare Al-Sb-Y-Mg modifier

[0034] The elemental composition of the modified agent is designed in terms of weight percentage as Al: 92%, Sb: 5%, Y: 2%, Mg: 1%.

[0035] Raw materials such as aluminum ingots, antimony ingots, yttrium ingots, and magnesium ingots are prepared according to the pre-designed composition of the modifier; the graphite crucible is placed in the resistance furnace and the resistance furnace is heated to 450°C, which will account for 92% of the weight percentage of the modifier. The ingot is put into a graphite crucible, and a layer of dry aluminum covering agent accounting for 2% by weight of the modificator is scattered on it; then the resistance furnace is heated to 800 ° C, and after the aluminum ingot is completely melted, the antimony ingot, yttrium ingot , magnesium ingots were successively added to the molten aluminum, wherein the additions of antimony ingots, yttrium ingots and magnesium ingots accounted for 5%, 2% and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com