Improved amino baking varnish inverse emulsion, preparation method thereof, and method for preparing baking varnish coating by using improved amino baking varnish inverse emulsion

A technology of amino baking varnish and reverse emulsion, which is applied in the field of modified amino baking varnish reverse emulsion, which can solve the problems of incompatibility and poor stability of nano-titanium dioxide, achieve high stability and dispersion, and reduce pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

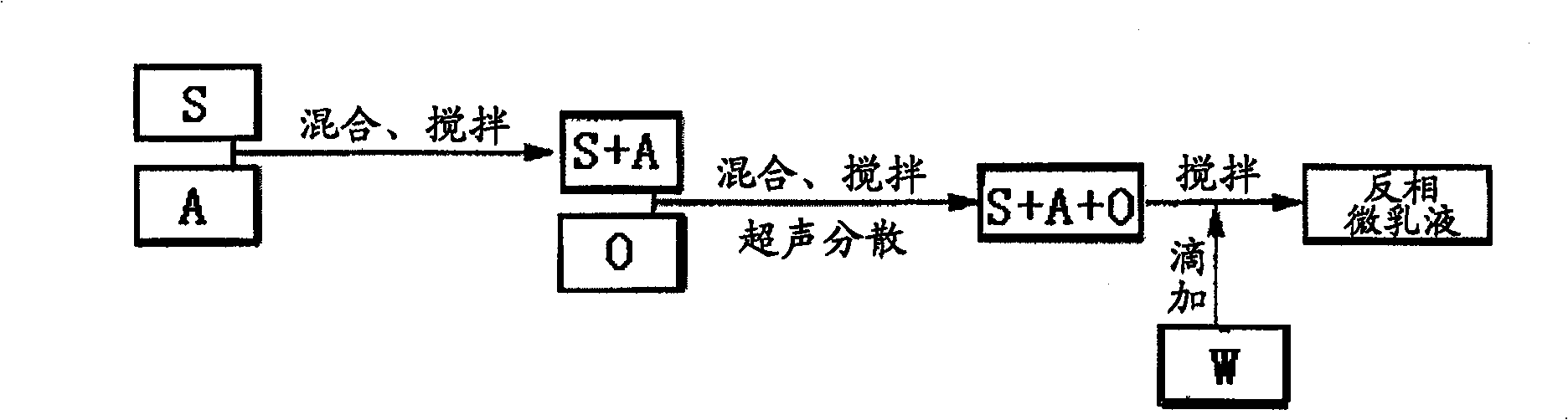

Method used

Image

Examples

Embodiment 1

[0152] (1) Nano-TiO 2 Preparation of aqueous system

[0153] Take 100ml H 2 O, add 0.15g sodium dodecylsulfonate and 3g nano-TiO 2 , for grinding, and adding an appropriate amount of NH 3 ·H 2 O to adjust the pH value to 8.5, followed by ultrasonic dispersion to obtain nano-TiO 2 aqueous phase system.

[0154] (2) Preparation of a mixture of acrylic amino baking varnish emulsion, compound emulsifier and co-emulsifier

[0155] Weigh 8.2g of Span80 and 1.8g of Tween60 (the hydrophilic-lipophilic balance (composite HLB) of the composite emulsifier is 12.99: HLB=82%×14.9+18%×4.3=12.99) and 1.5g of cyclohexane Alcohol co-emulsifier, the three are mixed at room temperature and stirred for half an hour, then add 10g of acrylic amino baking varnish emulsion, and continue stirring for one hour at room temperature to prepare a mixture of acrylic amino baking varnish emulsion, compound emulsifier and co-emulsifier.

[0156] (3) Preparation of modified inverse emulsion

[0157] In...

Embodiment 2

[0172] (1) Nano-TiO 2 Preparation of aqueous system

[0173] Take 100ml H 2 O, add 0.1g sodium dodecylsulfonate and 2g nano-TiO 2 , for grinding, and adding an appropriate amount of NH 3 ·H 2 O to adjust the pH value to 8.5, followed by ultrasonic dispersion to obtain nano-TiO 2 Aqueous system.

[0174] (2) Preparation of a mixture of acrylic amino baking varnish emulsion, compound emulsifier and co-emulsifier

[0175] Weigh 8.5g of Span80 and 1.5g of Tween60 (the hydrophilic-lipophilic balance (composite HLB) of the composite emulsifier is 13.31: HLB=85%×14.9+15%×4.3=13.31) and 1.5g of cyclohexane Alcohol co-emulsifier, the three are mixed at room temperature and stirred for half an hour, then add 16g of acrylic amino baking varnish emulsion, and continue stirring for one hour at room temperature to obtain a mixture of acrylic amino baking varnish emulsion, composite emulsifier and co-emulsifier.

[0176] (3) Preparation of modified inverse emulsion

[0177] In the mi...

Embodiment 3

[0181] (1) Nano-TiO 2 Preparation of aqueous system

[0182] Take 100ml H 2 O, add 0.08g sodium dodecylbenzenesulfonate and 1g nano-TiO 2 , for grinding, and adding an appropriate amount of NH 3 ·H 2 O to adjust the pH value to 8.5, followed by ultrasonic dispersion to obtain nano-TiO 2 aqueous phase system.

[0183] (2) Preparation of a mixture of acrylic amino baking varnish emulsion, compound emulsifier and co-emulsifier

[0184] Weigh 8.0g of Span80 and 2.0g of Tween60 (the hydrophilic-lipophilic balance (composite HLB) of the composite emulsifier is 12.78: HLB=80%×14.9+20%×4.3=12.78) and 1.5g of cyclohexane Alcohol co-emulsifier, the three are mixed at room temperature and stirred for half an hour, then add 20g of acrylic amino baking varnish emulsion, and continue stirring for one hour at room temperature to prepare a mixture of acrylic amino baking varnish emulsion, composite emulsifier and co-emulsifier.

[0185] (3) Preparation of modified inverse emulsion

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com