Method for producing light calcium carbonate and coproducing hydrogen sulfide by using crude calcium sulfide

A light calcium carbonate, hydrogen sulfide technology, applied in the directions of hydrogen sulfide, calcium carbonate/strontium/barium, etc., can solve the problems of industrial by-product gypsum polluting the environment and low impurity content, and achieve low solid impurity content and low impurity content. , the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Raw material 1: Coarse calcium sulfide, collection location: Guizhou Xiyang Fertilizer Co., Ltd.

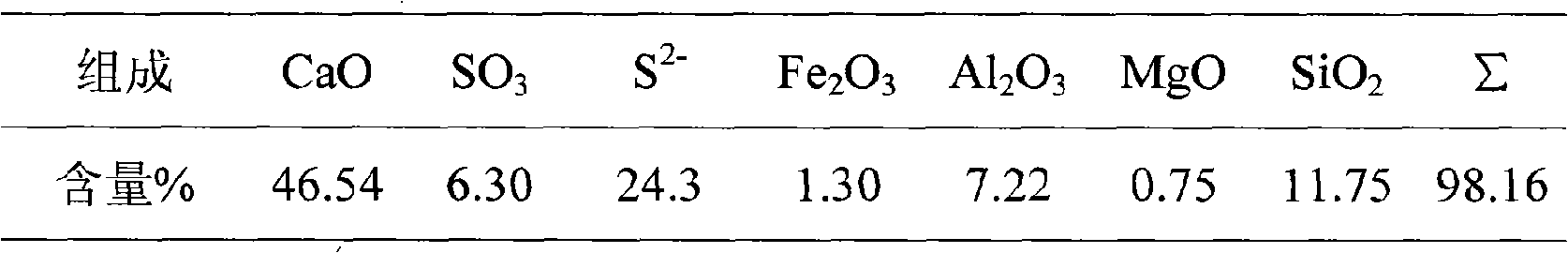

[0026] The chemical composition of crude calcium sulfide is shown in the table below

[0027]

[0028] Raw material 2: carbon dioxide (synthetic ammonia decomposed gas, content 93%), collection location: Guizhou Xiyang Fertilizer Co., Ltd.

Embodiment approach

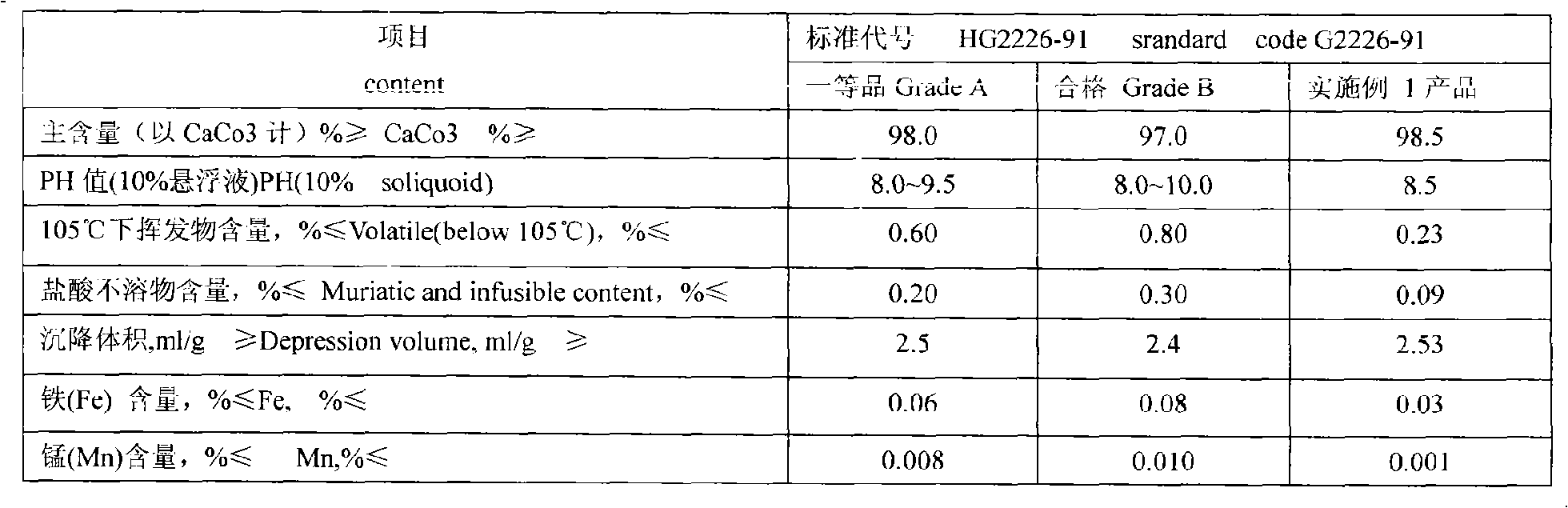

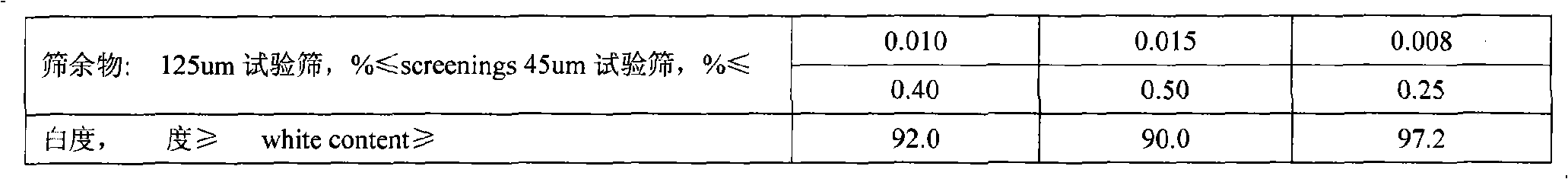

[0030] Add 100-mesh coarse calcium sulfide and saturated hydrogen sulfide solution into the dissolution tank with stirring device, and make a ratio of 1:100 solid-liquid ratio between coarse calcium sulfide and saturated hydrogen sulfide solution. After reacting for 40 minutes, the feed liquid is filtered with a leaf filter, the filter residue is washed and stacked in the residue yard, and the filtrate is pumped to the carbonization tower for carbonation, and the carbonation is normally degassed with synthetic ammonia. Control the reaction temperature to 50°C, and stop the aeration when the pH of the carbonization solution is 7. Store the hydrogen sulfide gas produced during the carbonation process in an air supply cabinet, filter the feed liquid with a leaf filter, pass through the excess hydrogen sulfide gas to make a saturated hydrogen sulfide solution and return it to the dissolution tank, and wash the filter cake with a rotary flash The light calcium carbonate collected b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com