Method and device for producing nano calcium carbonate by microwave drying

A nano-calcium carbonate, microwave drying technology, applied in calcium carbonate/strontium/barium, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of affecting the quality of nano-calcium carbonate products and long drying time of filter cakes , Reduce product whiteness and other issues, achieve the effect of improving the production environment, fast heating speed, and improving whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

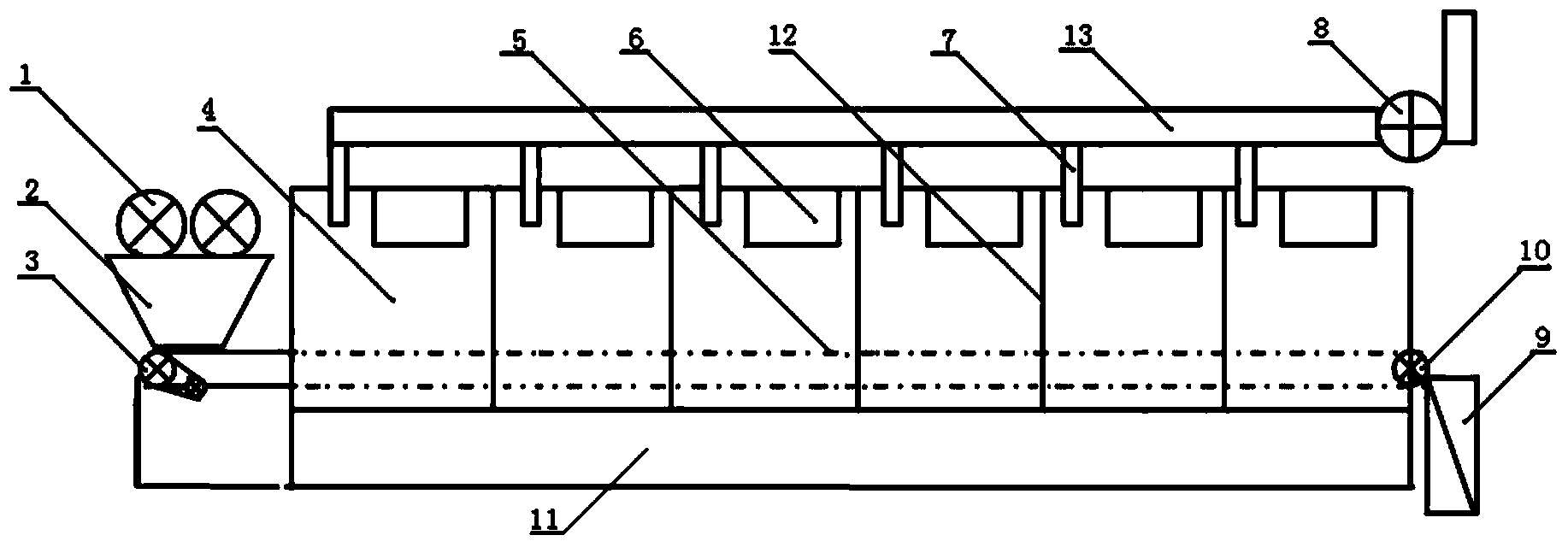

Image

Examples

Embodiment 1

[0025] A method utilizing microwave drying to produce nano-calcium carbonate is implemented according to the following steps:

[0026] ①Preparation of Ca(OH) 2 Raw seminal pulp: calcined with limestone to obtain calcium oxide, which is digested with water to obtain Ca(OH) 2 Raw pulp, then aged, sieved to remove impurities, and prepared Ca(OH) 2 seminal plasma;

[0027] ②Calcium carbonate cooked pulp: adjust Ca(OH) 2 The temperature and mass percent concentration of raw seminal plasma, temperature is controlled at 20 ℃, and mass percent concentration is controlled at 10%, then Ca(OH) 2 Raw seminal pulp is added to the bubbling carbonization tower reactor and CO 2The gas is carbonized by bubbling and carbonized, and the carbonization is stopped when the pH of the slurry is less than or equal to 7.5, and the calcium carbonate cooked slurry is obtained;

[0028] ③Preparation of active calcium carbonate filter cake: add surface treatment agent to the calcium carbonate cooked p...

Embodiment 2

[0033] A method utilizing microwave drying to produce nano-calcium carbonate is implemented according to the following steps:

[0034] ①Preparation of Ca(OH) 2 Raw seminal pulp: calcined with limestone to obtain calcium oxide, which is digested with water to obtain Ca(OH) 2 Raw pulp, then aged and sieved to remove impurities to obtain Ca(OH) 2 seminal plasma;

[0035] ②Calcium carbonate cooked pulp: adjust Ca(OH) 2 The temperature and mass percent concentration of raw seminal pulp, temperature is controlled at 8 ℃, and mass percent concentration is controlled at 5%, then Ca(OH) 2 Raw seminal pulp is added to the bubbling carbonization tower reactor and CO 2 The gas is carbonized by bubbling and carbonized, and the carbonization is stopped when the pH of the slurry is less than or equal to 7.5, and the calcium carbonate cooked slurry is obtained;

[0036] ③Preparation of active calcium carbonate filter cake: add surface treatment agent to the calcium carbonate cooked pulp,...

Embodiment 3

[0041] A method utilizing microwave drying to produce nano-calcium carbonate is implemented according to the following steps:

[0042] ①Preparation of Ca(OH) 2 Raw seminal pulp: calcined with limestone to obtain calcium oxide, which is digested with water to obtain Ca(OH) 2 Raw pulp, then aged, sieved to remove impurities, and prepared Ca(OH) 2 seminal plasma;

[0043] ②Calcium carbonate cooked pulp: adjust Ca(OH) 2 The temperature and mass percent concentration of raw seminal pulp, temperature is controlled at 25 ℃, and mass percent concentration is controlled at 12%, then Ca(OH) 2 Raw seminal pulp is added to the bubbling carbonization tower reactor and CO 2 The gas is carbonized by bubbling and carbonized, and the carbonization is stopped when the pH of the slurry is less than or equal to 7.5, and the calcium carbonate cooked slurry is obtained;

[0044] ③Preparation of active calcium carbonate filter cake: add surface treatment agent to the calcium carbonate cooked pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com