Temperature device for controlling heating or cooling of reaction kettle

A technology of temperature control device and reaction kettle, which is applied in temperature control, non-electric variable control, control/regulation system, etc., can solve the problems of high dependence on skilled workers and low control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

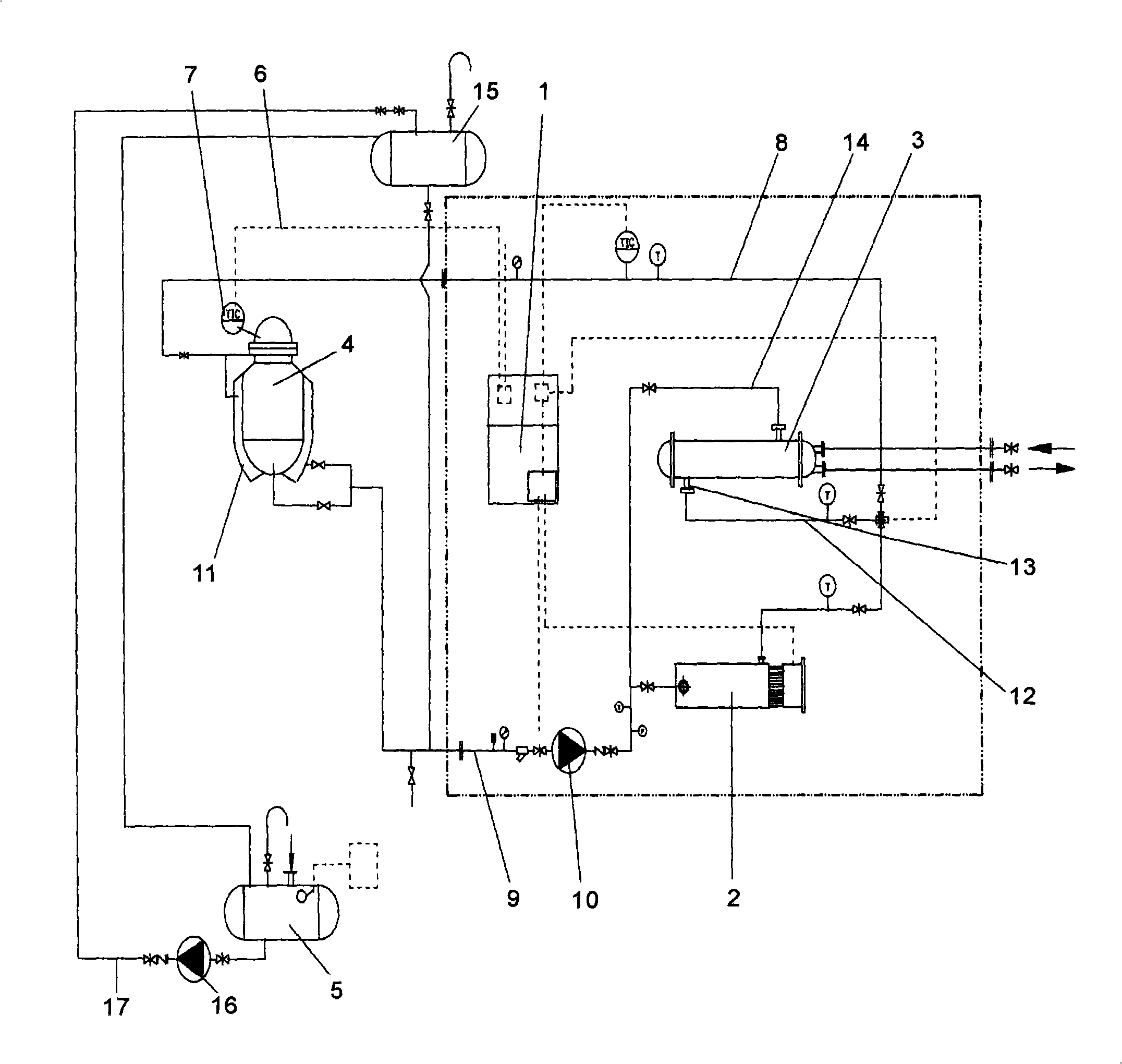

[0018] exist figure 1 In the three-dimensional schematic diagram of a temperature control device for controlling the heating or cooling of the reactor shown in the figure, it consists of the electric control cabinet 1 system, the heating system 2, the cooling system 3, the reactor 4 system, the oil storage tank 5 system and the oil delivery system constitute.

[0019] The signal transmission line 6 of the electric control cabinet 1 system is connected with the temperature sensor 7 on the reactor 4 body, connected with the switch cabinet and the three-way valve of the heating 2 system, and connected with the oil pump 10 on the oil supply pipe 8 and the oil return pipe 9 ; The electric control cabinet 1 is connected to the power supply.

[0020] The oil supply pipe 8 output by the heating 2 system is connected with the oil outlet pipe 14 of the cooler 3 through a three-way valve, and the outlet of the three-way confluence valve is connected with the oil inlet pipe of the reacto...

Embodiment 2

[0026] Adopt the working principle of embodiment one, heating source adopts steam, electricity, gas; Cooling source adopts factory cooling water or chilled water, or refrigeration equipment; Adopt the working principle of embodiment one, control the temperature of multiple reactors 4 simultaneously. This new complete set of equipment integrates the traditional characteristics of the system. The parts selection design matches the system and can be adjusted within a certain range. It works according to the process setting curve and can control one reactor 4 or multiple reactors 4 at the same time. temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com