Chemical mechanical polishing of moisture sensitive surfaces and compositions therefor

A technology for blending, polishing surfaces, applied in the field of microemulsions, which can solve problems such as loss of efficiency in step height reduction, loss of ability to remove surface roughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

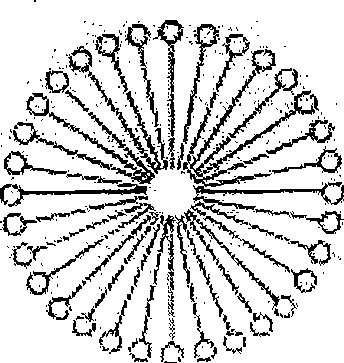

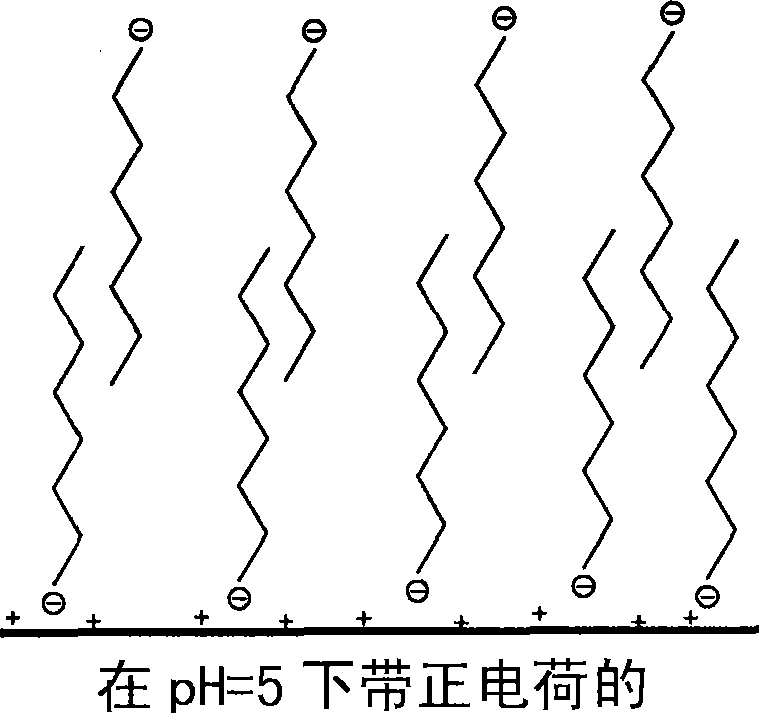

Image

Examples

Embodiment 1

[0060] Embodiment 1 (L2 microemulsion)

[0061] A solution of sodium dodecyl sulfate (SDS) was prepared by dissolving 10.0 grams of SDS in 13.0 grams of DI (deionized) water. To the above solution, 77.0 grams of pentanol was added. The solution was then filtered using 0.4 μm filter paper. Samples of potassium diphosphate (KDP) crystals were mounted on homemade supports and then polished on polyurethane pads (IC1000, Rohm & Haas) with a bench toppolisher (Struer Labopol-5). Downforce is set at about 3-5psi. The table speed was set at 50-150 rpm. Adjust the slurry flow rate to approximately 60 mL / min. After polishing for 3 minutes, the samples were then cleaned with amyl alcohol and air dried. The material removal rate was then calculated based on the weight loss after polishing. The table below lists the removal rates under various conditions.

[0062] Table 1. Material removal rate (MRR) of KDP crystals

[0063] Downforce (PSI) Table speed (rpm) MRR(nm / ...

Embodiment 2

[0065] To 950 g of the solution described in Example 1 (10% water, 13% SDS and 77% pentanol, all % by weight based on the total weight of the solution) were added 50 g of fumed silica (Degussa 200). The resulting slurry was then used in polishing similar to that described in Example 1. The removal rates under various conditions are listed in Table 2.

[0066] Table 2. Material removal rates of KDP crystals

[0067] Downforce (PSI) Table speed (rpm) MRR(nm / min) 4 100 12030 5 100 15300 5 150 17900

Embodiment 3

[0069] Solutions were prepared according to the same procedure as described in Example 1, except for the drop in water (3 grams). A series of polishes were tested under one of the test conditions in Table 1 (5 psi downforce, 150 rpm table speed and 60 mL / min slurry flow rate). Material removal rate and step height changes were detected every 30 seconds for KDP samples. Table 3 lists the material removal and step height reduction over time.

[0070] Table 3. Material removal and step height reduction over polishing time for Example 3

[0071] polished

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com