Contact bonding pad for reducing parasitic capacitance and manufacturing method thereof

A technology for contacting pads and pads, which is applied in the direction of circuits, electrical components, and electrical solid devices, can solve the problems of reducing the effect of parasitic capacitance, not easy to add STI layers, and restrictions, so as to reduce the value of parasitic capacitance and increase the preparation process The effect of simple cost and preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

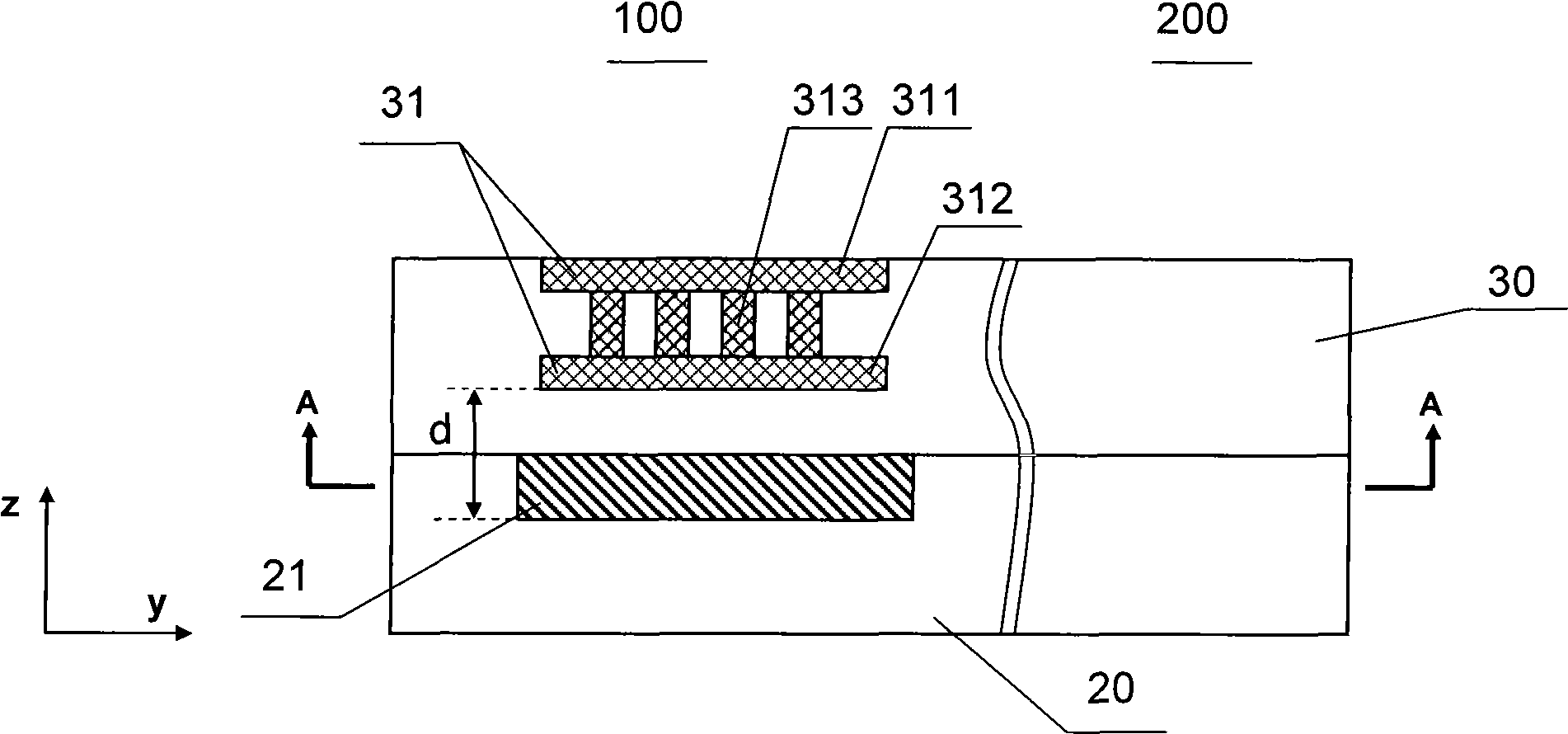

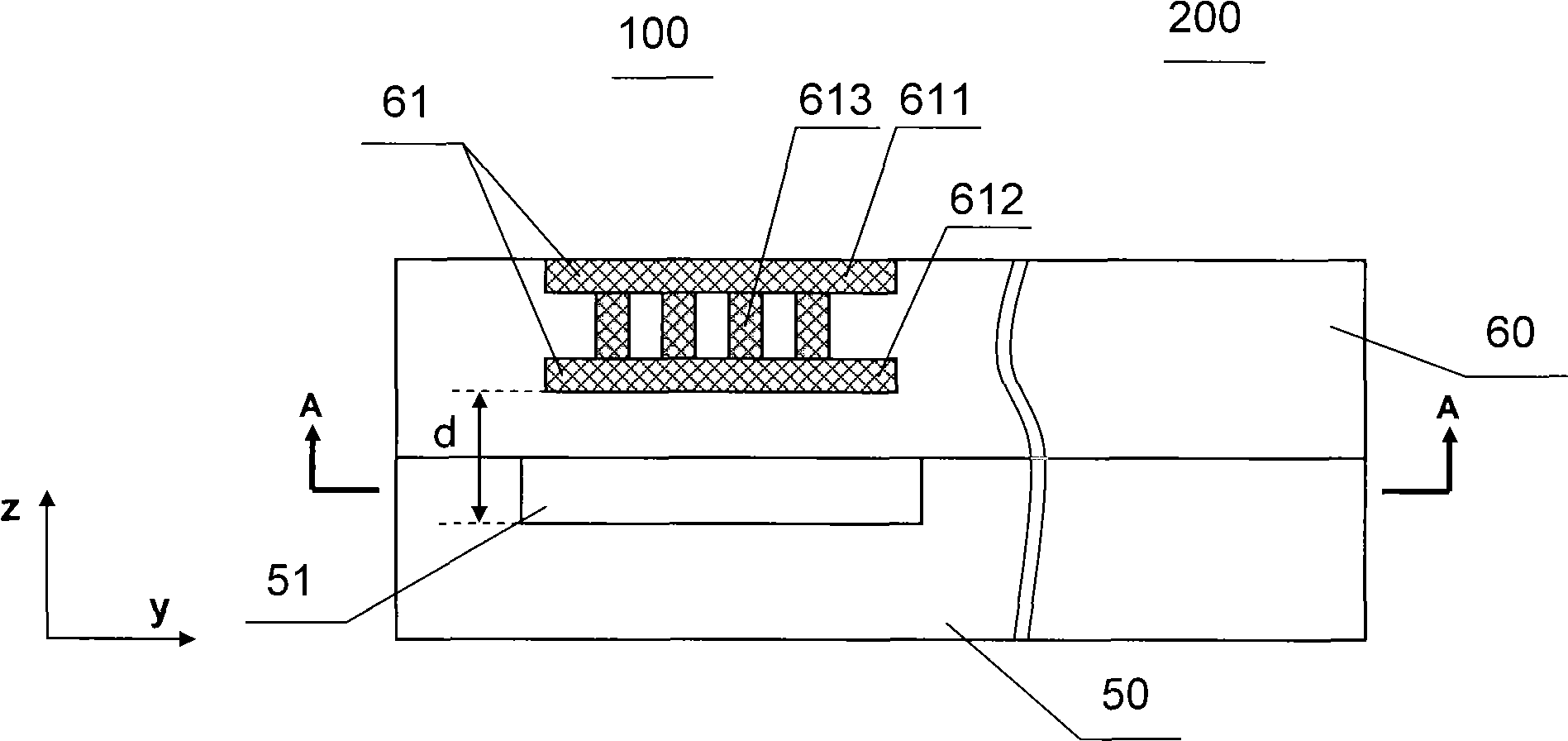

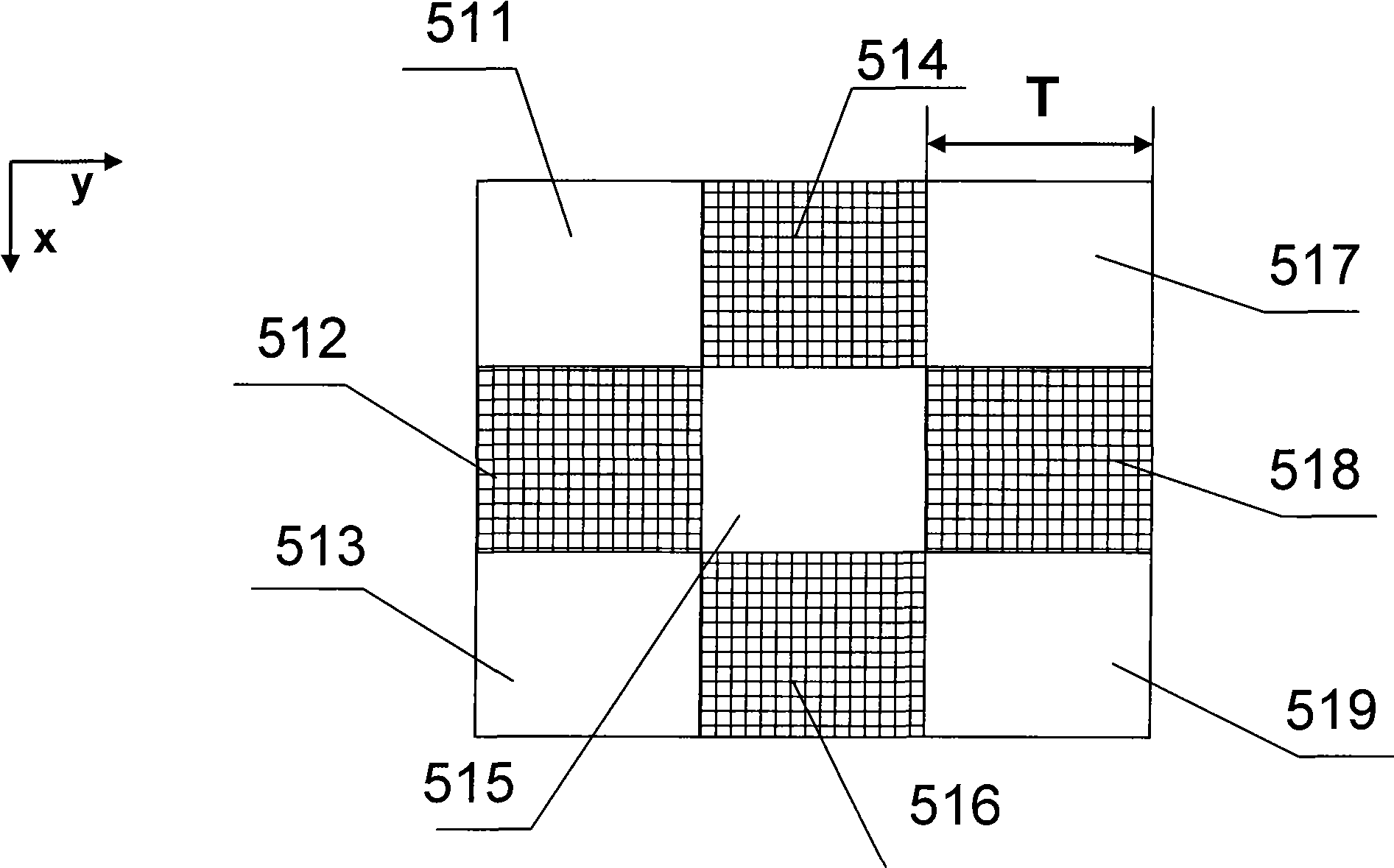

[0027] figure 2 Shown is a schematic structural diagram of the contact pad provided by the present invention. like figure 2 As shown, this embodiment provides a schematic diagram of a contact pad formed in the semiconductor substrate 50 and the interconnect structure layer 60, wherein the Z direction is a direction perpendicular to the upper surface of the semiconductor substrate. The interconnect structure layer 30 includes multiple metal layers, and the contact pad includes a pad metal layer 61. In this embodiment, the pad metal layer 61 includes a first layer of pad metal layer 611, a second layer of pad metal layer 612 And a hole (Via) 613 for connecting the first layer of pad metal layer and the second layer of pad metal layer, wherein the first layer of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com