Lubricating pump

A lubricating pump and a combined technology, applied in the field of lubricating pumps, can solve the problems of high manufacturing cost, low operating efficiency, complexity, etc., and achieve the effects of long service life, strong self-priming performance and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

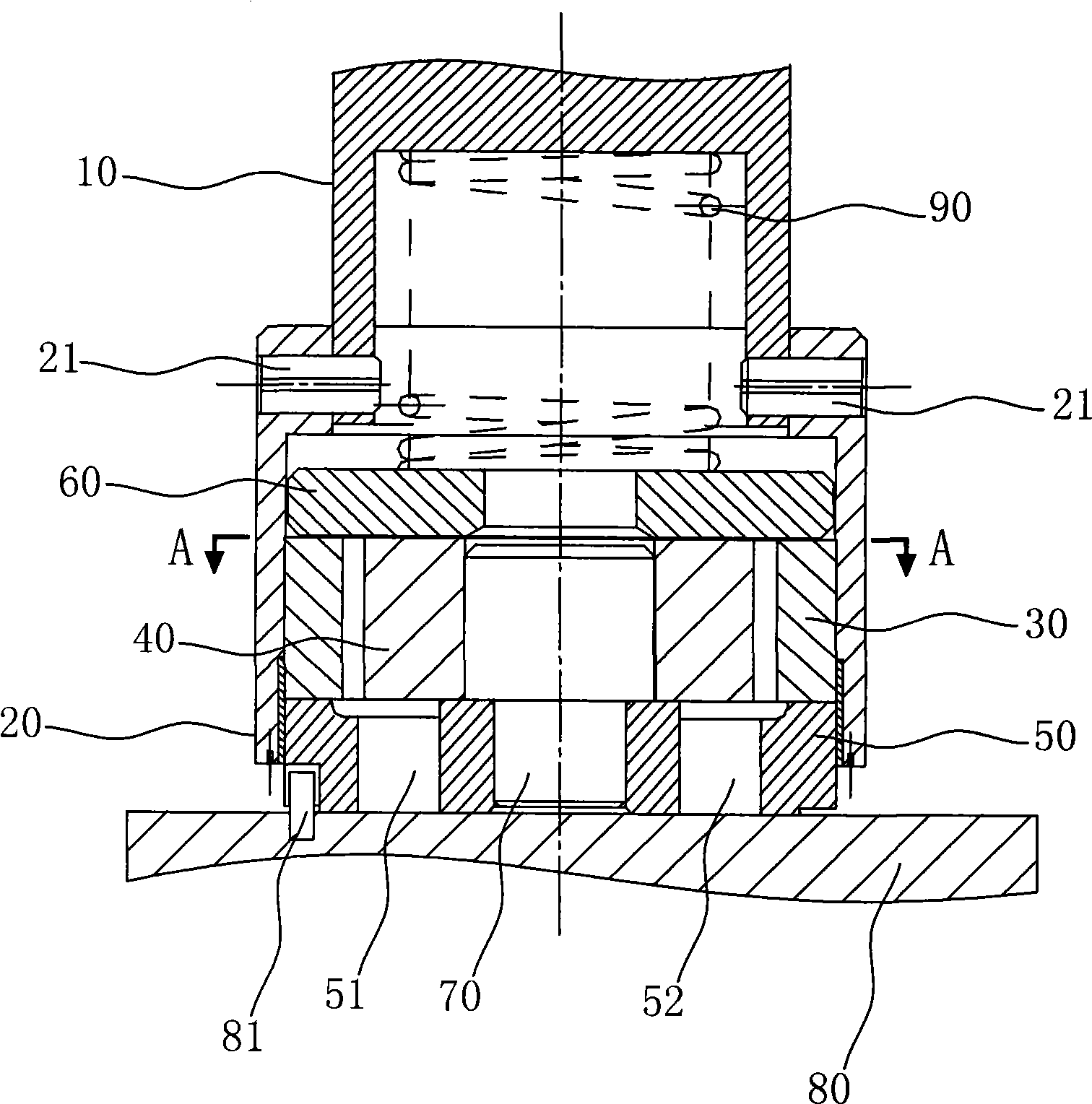

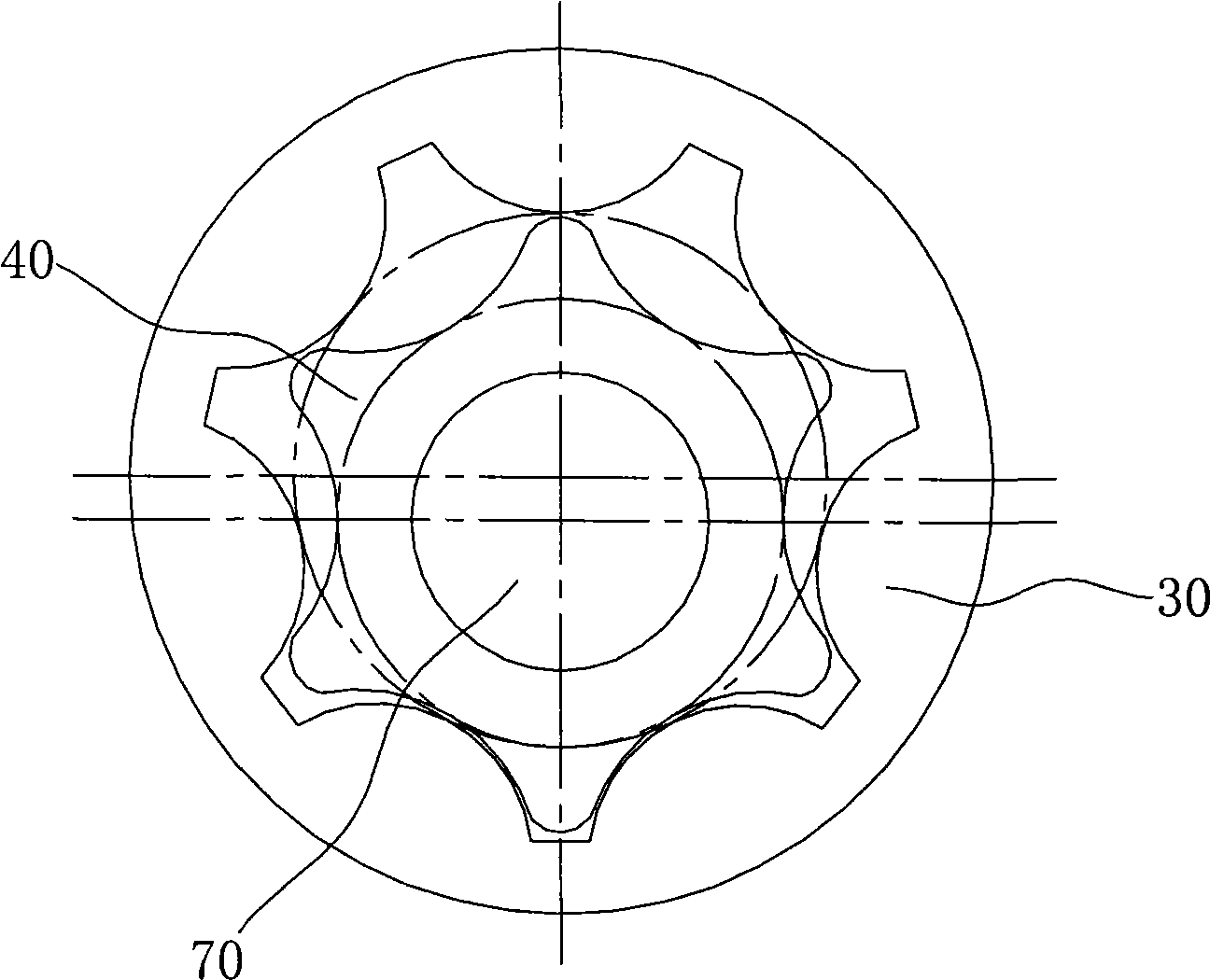

[0008] like figure 1 , 2 As shown, the cylindrical casing 20 of the lubricating pump is fixedly connected with the drive shaft 10, the inner side of the casing 20 is provided with an outer rotor 30 fixedly connected with it, and the inner side of the outer rotor 30 is provided with a cycloidal gear meshing with it. The inner rotor 40 of the inner and outer rotors 40, 30 is provided with a sealing cover plate 50 between the end faces of the inner and outer rotors 40, 30 away from the drive shaft 10 and the installation reference surface 80 of the lubricating pump. The plate 50 is provided with an eccentric hole and an inlet 51 and an outlet 52 for the circulation of lubricating oil. The rotating shaft 70 passes through the inner rotor 40 and the eccentric hole in turn and abuts against the installation reference surface 80. The drive shaft 10 drives When the housing 20 rotates, lubricating oil is sucked from the inlet 51 on the sealing cover 50 , and is discharged from the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com