Low dropout decompression transfer line

An oil transfer line, low pressure drop technology, applied in rigid pipes, distillation separation, pipes, etc., can solve the problems of high outlet temperature of decompression furnace, poor oil vaporization effect, and influence on oil extraction rate, etc. Outlet temperature, improving product quality, optimizing the effect of vaporization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is compared with prior art as follows:

[0021] Figure 6 It is a schematic diagram of the structure of a petrochemical company's decompression to oil transfer line. The decompression furnace tube is a four-way exit, which is drawn out at the top of the furnace, goes vertically upwards and passes through a 90-degree elbow, then along a section of horizontal straight pipe, and then passes through a horizontal 45-degree elbow, and the four-way transition section is combined and inserted into the low-speed section, and the straight pipe of the low-speed section is horizontal at an angle of 45 degrees. The low-speed section has a diameter of 1.4m and a length of about 28m.

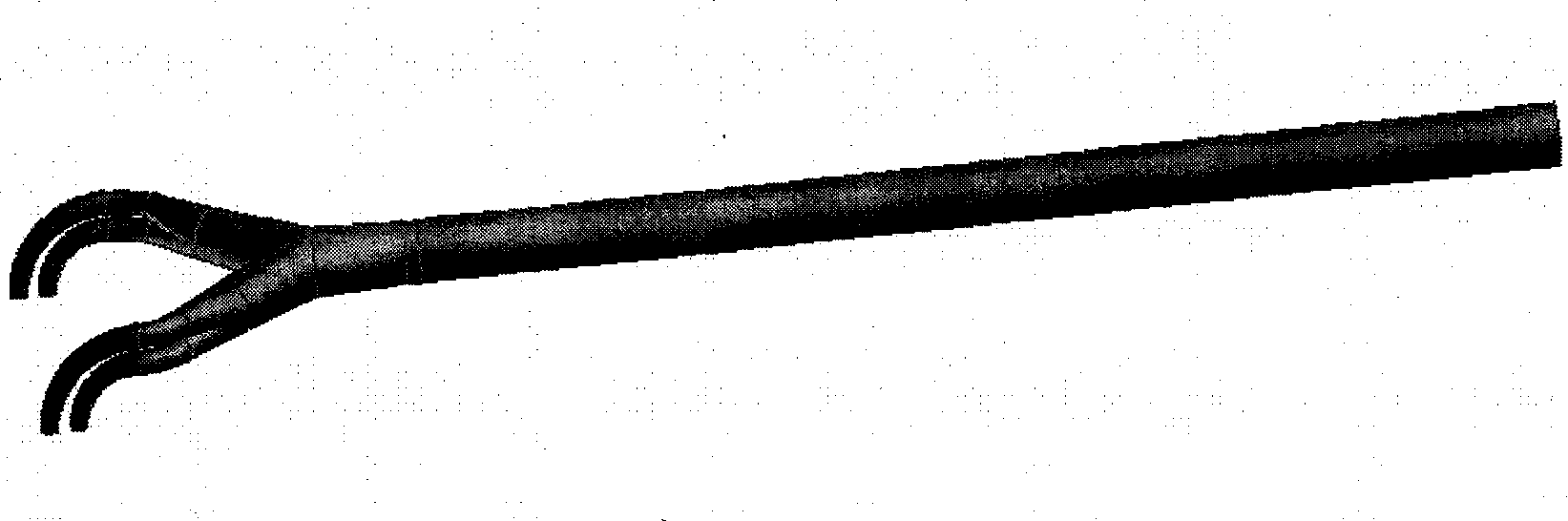

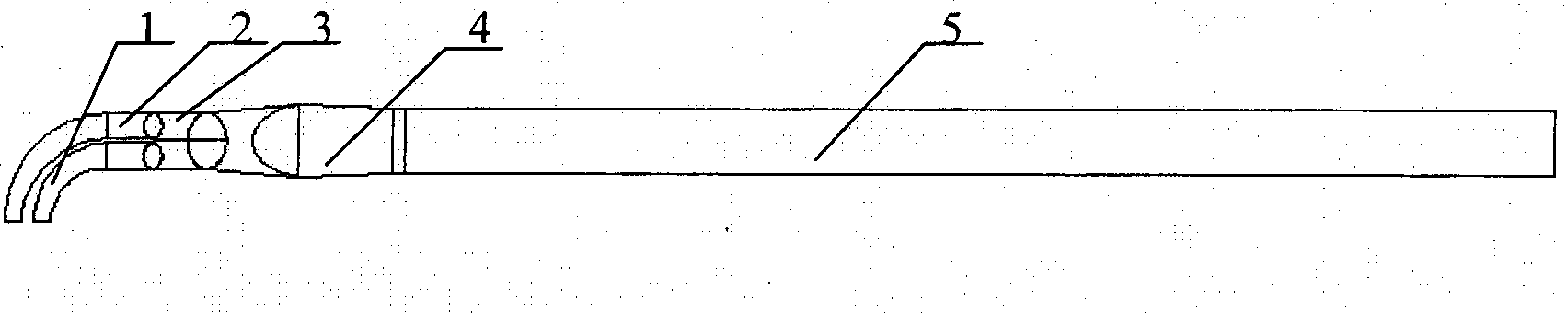

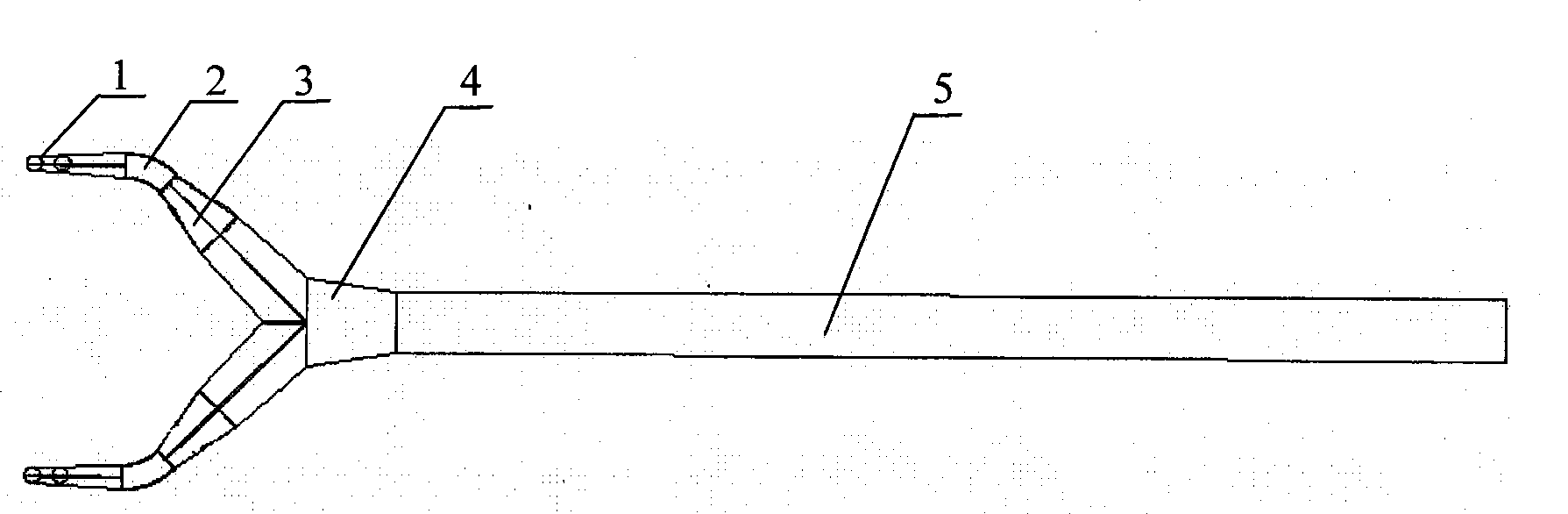

[0022] Will Figure 6 The structure of the oil transfer line is optimized, and the optimized structure is as follows Figure 1a Fig. 1b and Figure 1c As shown, a 90-degree expanding elbow 1 with a radius of curvature of 3 to 6 times the diameter of the elbow is connected to a 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com