Heat treatment quenching and tempering method

A tempering and heating furnace technology, applied in the field of metal heat treatment, can solve the problems of low yield, difficult batch operation, complicated process, etc., achieve ideal plasticity index, realize batch operation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1 (taking 25# casting as example)

[0019] A kind of heat treatment conditioning method, it comprises the following steps:

[0020] ① Put the casting into the heating furnace, heat it to a temperature between 900 and 950°C and keep it warm. The holding time is determined according to the thickness of the casting. The calculation formula is: casting thickness / holding time = 1.8mm / min, the purpose is to obtain unbalanced Structure, because the casting is ultra-fine due to the nucleation characteristics of the non-equilibrium structure austenitization process, and the interface ratio increases;

[0021] ② After heat preservation, take out the casting and put it in water to cool;

[0022] ③ Put the cooled casting back into the heating furnace, heat it to a temperature between 760 and 780°C and keep it warm. The holding time is determined according to the thickness of the casting. The calculation formula is the same as step ①. The purpose is to heat in the dual-p...

Embodiment 2

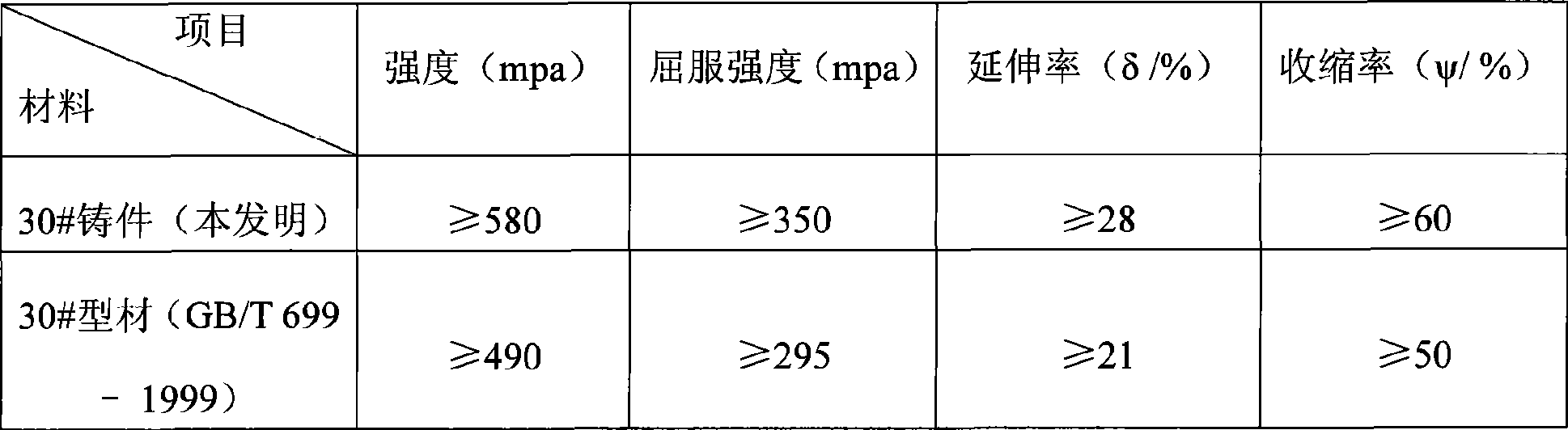

[0029] Embodiment 2 (taking 30# casting as example)

[0030] A kind of heat treatment conditioning method, it comprises the following steps:

[0031] ①Put the casting into the heating furnace, heat it to a temperature between 900 and 950°C and keep it warm. The holding time is determined according to the thickness of the casting. The calculation formula is: casting thickness / holding time=1.7mm / min, the purpose is to obtain unbalance Structure, because the casting is ultra-fine due to the nucleation characteristics of the non-equilibrium structure austenitization process, and the interface ratio increases;

[0032] ② After heat preservation, take out the casting and put it in water to cool;

[0033] ③ Put the cooled casting back into the heating furnace, heat it to a temperature between 760 and 780°C and keep it warm. The holding time is determined according to the thickness of the casting. The calculation formula is the same as step ①. The purpose is to heat in the dual-phase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com