Process for producing silicane

A production process and silane technology, applied in the direction of silicon hydride, etc., can solve the problem of low silane conversion rate and achieve the effect of improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

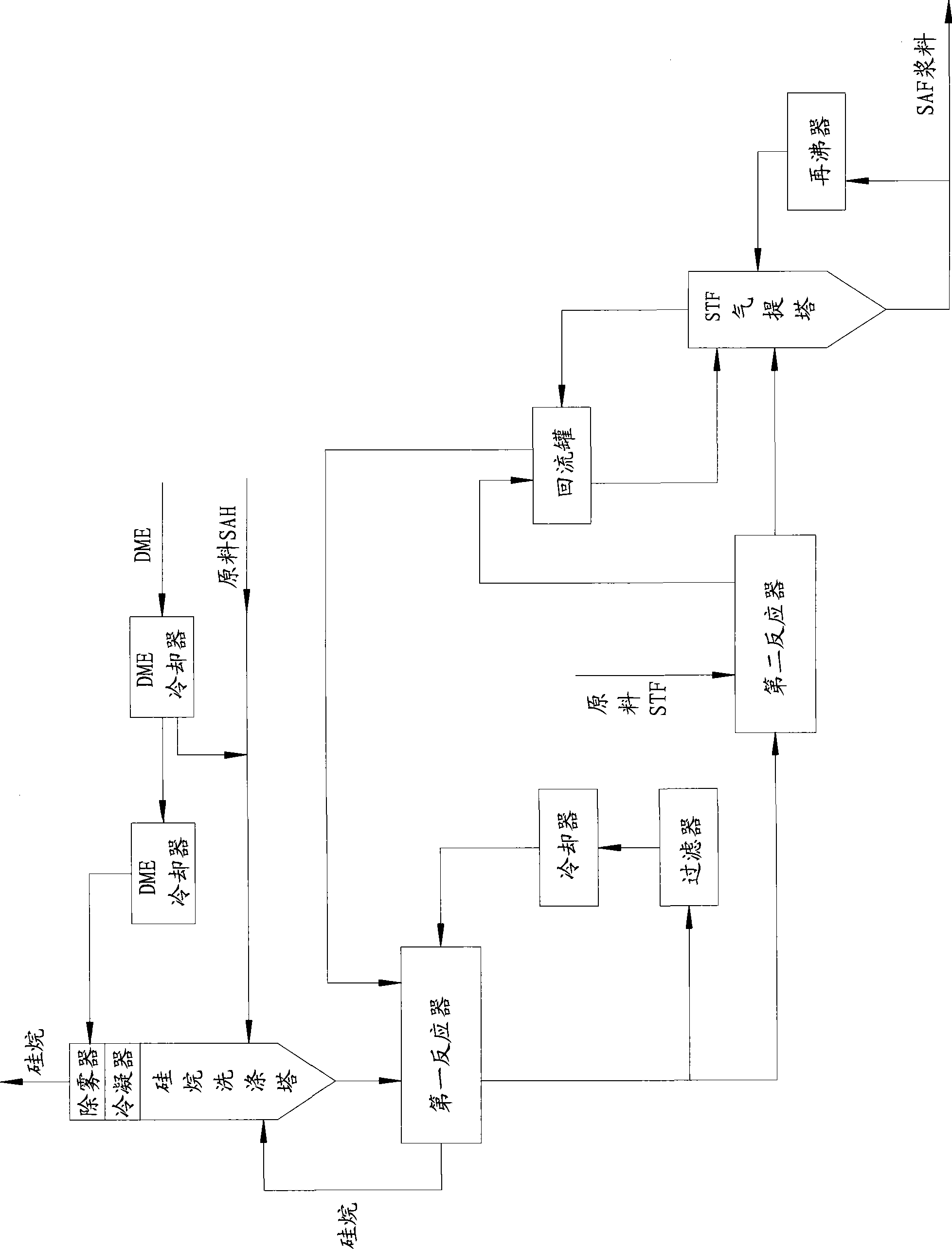

Method used

Image

Examples

Embodiment 1

[0030] In the SAH raw material tank, SAH is diluted with DME to adjust the concentration to 7%, and the SAH flow rate is set to 77kg / min (kg / min). After cooling and dilution, SAH first enters the silane scrubber, and then enters the first reactor. React with the unreacted STF from the second reactor, the reaction product is divided into two parts, the first part is about 90-95% of the SAH flow, and returns to the first reactor through a filter and water cooler, To adjust the temperature of the reactor; the second part enters the second reactor to react with the raw material STF. The reaction conditions in the first reactor are that the temperature is 30-40° C. and the pressure is 0.03-0.06 MPa (megapascal). The reaction conditions in the second reactor are that the temperature is 45-55° C., and the pressure is 0.1-0.4 MPa. The flow rate of the raw material STF is 100 mol / min (mol / min). Both the first reactor and the second reactor are equipped with stirrers, and the stirring...

Embodiment 2

[0036] In the SAH raw material tank, SAH is diluted with DME to adjust the concentration to 10%, and the SAH flow rate is set to 54kg / min (kg / min). After cooling and dilution, SAH first enters the silane scrubber, and then enters the first reactor. React with the unreacted STF from the second reactor, the reaction product is divided into two parts, the first part is about 90-95% of the SAH flow, and returns to the first reactor through a filter and water cooler, To adjust the temperature of the reactor; the second part enters the second reactor to react with the raw material STF. The reaction conditions in the first reactor are that the temperature is 30-40° C. and the pressure is 0.06-0.08 MPa (megapascal). The reaction conditions in the second reactor are that the temperature is 45-55° C., and the pressure is 0.1-0.4 MPa. The flow rate of the raw material STF is 100 mol / min (mol / min). Both the first reactor and the second reactor are equipped with stirrers, and the stirrin...

Embodiment 3

[0043] In the SAH raw material tank, SAH is diluted with DME to adjust the concentration to 10%, and the SAH flow rate is set to 54kg / min (kg / min). After cooling and dilution, SAH first enters the silane washing tower, and then enters the first reactor. React with the unreacted STF from the second reactor, the reaction product is divided into two parts, the first part is about 90-95% of the SAH flow, and returns to the first reactor through a filter and water cooler, To adjust the temperature of the reactor; the second part enters the second reactor to react with the raw material STF. The reaction conditions in the first reactor are that the temperature is 30-40° C. and the pressure is 0.03-0.06 MPa (megapascal). The reaction conditions in the second reactor are that the temperature is 45-55° C., and the pressure is 0.1-0.4 MPa. The flow rate of the raw material STF is 100 mol / min (mol / min). Both the first reactor and the second reactor are equipped with stirrers, and the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com