Low frog degree BOPP film and production process thereof

A low-haze, thin-film technology, applied in layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of high price of transparent nucleating agents, affecting product stability, carbonization, etc., and achieve product stability. Good performance, low production cost, and the effect of reducing haze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

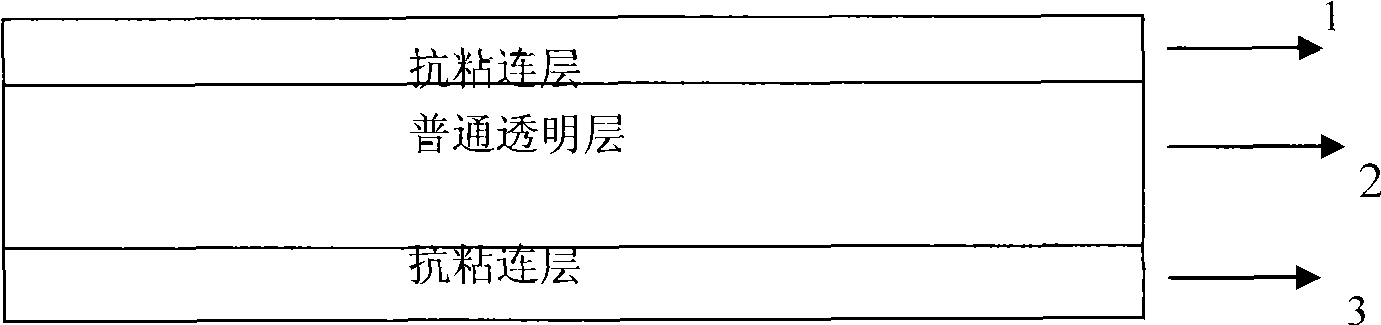

[0024] Use biaxially stretched polypropylene resin to form a film with a three-layer structure after co-extrusion and biaxial stretching. The top layer 1 and bottom layer 3 are anti-blocking layers, and the middle layer 2 is an ordinary transparent layer, such as figure 1 shown. The top layer 1 and bottom layer 3 of the film contain 1.5% antiblocking agent by weight percentage, and the rest is polypropylene resin; the middle layer 2 contains 0.5% antistatic agent by weight percentage, and the rest is polypropylene resin. The anti-blocking agent is synthetic silica with a particle size of 2-5 microns. One side of the film is corona treated.

[0025] The film production process according to the above ratio:

[0026] a. During co-extrusion, the polypropylene resin is melt-extruded at 230°C to 250°C and passed through the die to form a cast sheet;

[0027] b. The cast sheet is quenched and crystallized at 10-20°C to form a thick sheet;

[0028] c. After preheating at 120°C-139...

Embodiment 2

[0032] Use biaxially stretched polypropylene resin to form a film with a three-layer structure after co-extrusion and biaxial stretching. The top layer 1 and bottom layer 3 are anti-blocking layers, and the middle layer 2 is an ordinary transparent layer, such as figure 1 shown. The top layer 1 and the bottom layer 3 of the film contain 2.5% antiblocking agent by weight percentage, and the rest is polypropylene resin; the middle layer 2 contains 1.5% antistatic agent by weight percentage, and the rest is polypropylene resin. The anti-blocking agent is synthetic silica with a particle size of 2-5 microns. One side of the film is corona treated.

[0033] The film production process according to the above ratio:

[0034] a. During co-extrusion, the polypropylene resin is melt-extruded at 230°C to 250°C and passed through the die to form a cast sheet;

[0035] b. The cast sheet is quenched and crystallized at 10-20°C to form a thick sheet;

[0036] c. After preheating at 120°C...

Embodiment 3

[0040] Using biaxially stretched polypropylene resin to form a three-layer film after co-extrusion and biaxially stretching, the top layer 1 and bottom layer 3 are anti-blocking layers, and the middle layer 2 is an ordinary transparent layer. The top layer 1 and the bottom layer 3 of the film contain 2% antiblocking agent by weight percentage, and the rest is polypropylene resin; the middle layer 2 contains 1% antistatic agent by weight percentage, and the rest is polypropylene resin. The anti-blocking agent is synthetic silica with a particle size of 2-5 microns. The film is corona treated on both sides.

[0041] The film production process according to the above ratio:

[0042] a. During co-extrusion, the polypropylene resin is melt-extruded at 230°C to 250°C and passed through the die to form a cast sheet;

[0043] b. The cast sheet is quenched and crystallized at 10-20°C to form a thick sheet;

[0044] c. After preheating at 120°C-139°C, the thick film is stretched long...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com