Method for carrying out oil dehydration by hydrophobic film

A hydrophobic membrane and oil technology, applied in the field of membrane separation, can solve the problems of non-continuous operation, large space occupation, high energy consumption, etc., and achieve the effects of not being easily polluted, easy to backwash, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

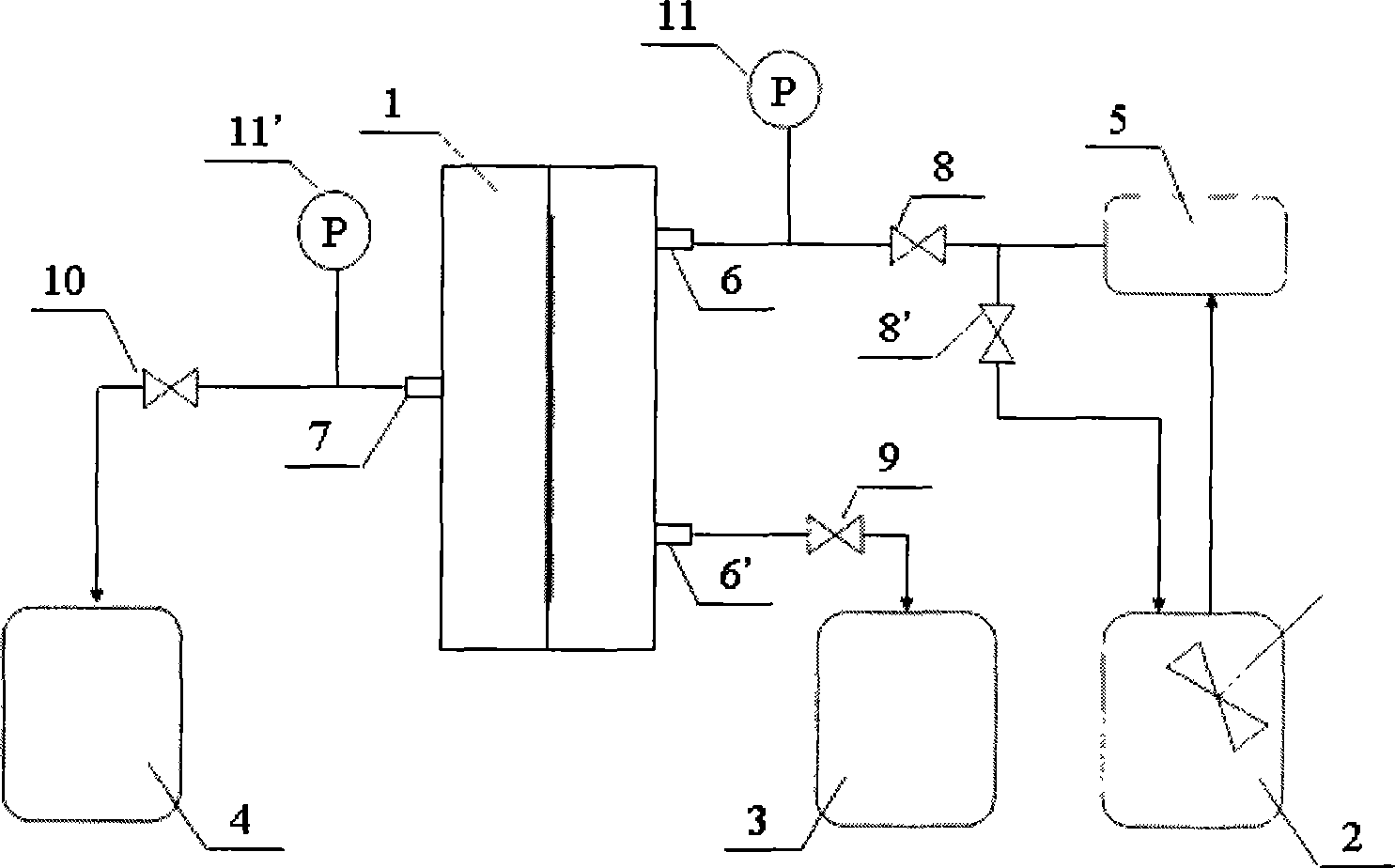

Method used

Image

Examples

Embodiment 1

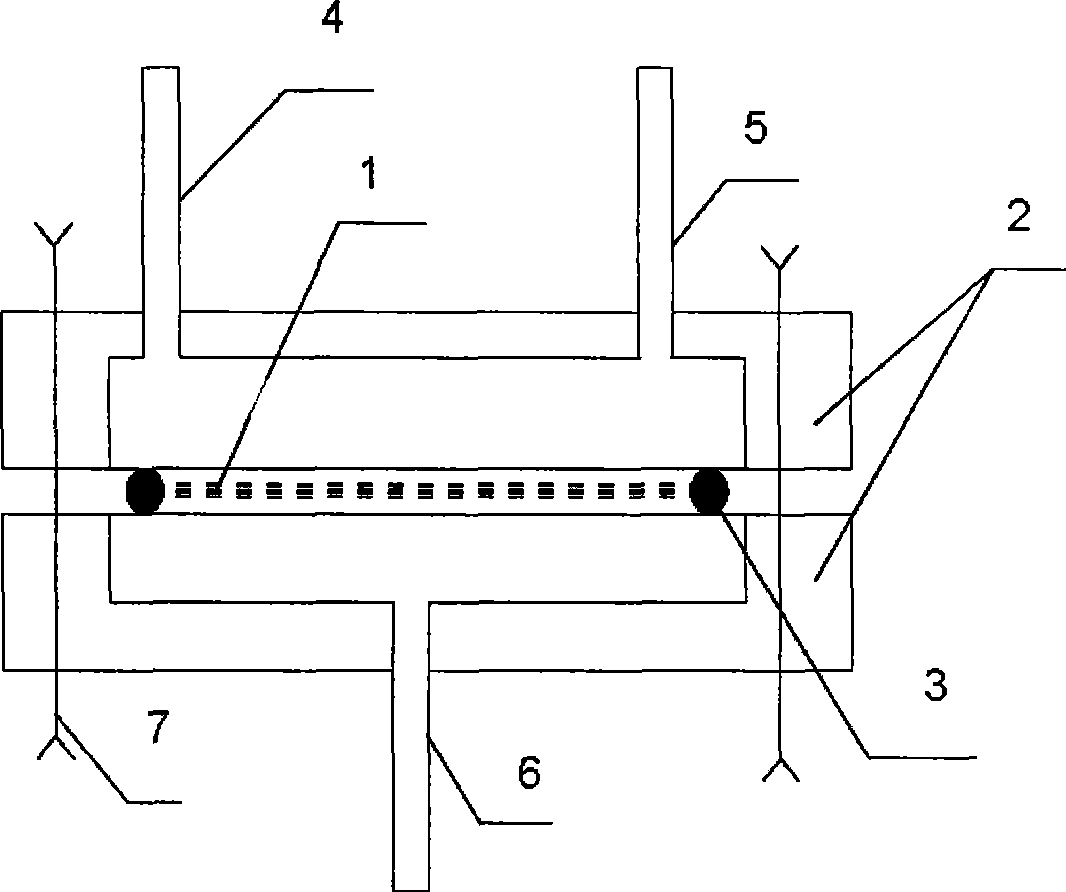

[0030] A. Encapsulate the hydrophobic membrane in the plate membrane module (1) for use. The hydrophobic membrane is made of polytetrafluoroethylene (PTFE) membrane with a pore size of 1 μm and a porosity of 90%.

[0031] B. Add deionized water into the light oil, stir for 15 minutes, and prepare an oil-water mixture with a water content of 946 mg / L for use.

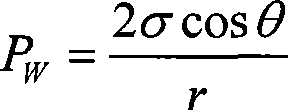

[0032] Put the above-mentioned light oil with a water content of 946mg / L into the raw material tank (2), stir continuously, and the temperature is 20°C, and use the pump (5) to transport the oil-water mixture from the feed port (6) into the membrane module (1 ), no additional pressure is applied, and the filtration is carried out by the static pressure of the oil-water mixture (the transmembrane pressure difference is about 0.001MPa). The filtration method is dead-end filtration, and the filtered oil is discharged and collected from the downstream outlet (7) of the membrane module into the container (4). The water cont...

Embodiment 2

[0035]A polytetrafluoroethylene hydrophobic membrane with a pore size of 2 μm and a porosity of 90% was selected, and aviation kerosene with an initial water content of 8356 mg / L was used. Other operations were the same as in Example 1. The water content of the filtered oil product is 286mg / L, and the water retention rate is 96.6%.

Embodiment 3

[0037] A polytetrafluoroethylene hydrophobic membrane with a pore size of 1 μm and a porosity of 80% was selected, and vacuum pump oil with an initial water content of 7683 mg / L was used, and other operations were the same as in Example 1. The water content of the filtered oil product is 360 mg / L, and the water retention rate is 95.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com