Hot pack paster

A technology of hot compresses and heating materials, applied in the field of medical and health products, can solve the problems of inconvenient carrying hot compresses, short storage time, and inconvenient travel for users, and achieve good health care effects, enhanced penetration, and accelerated drug absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

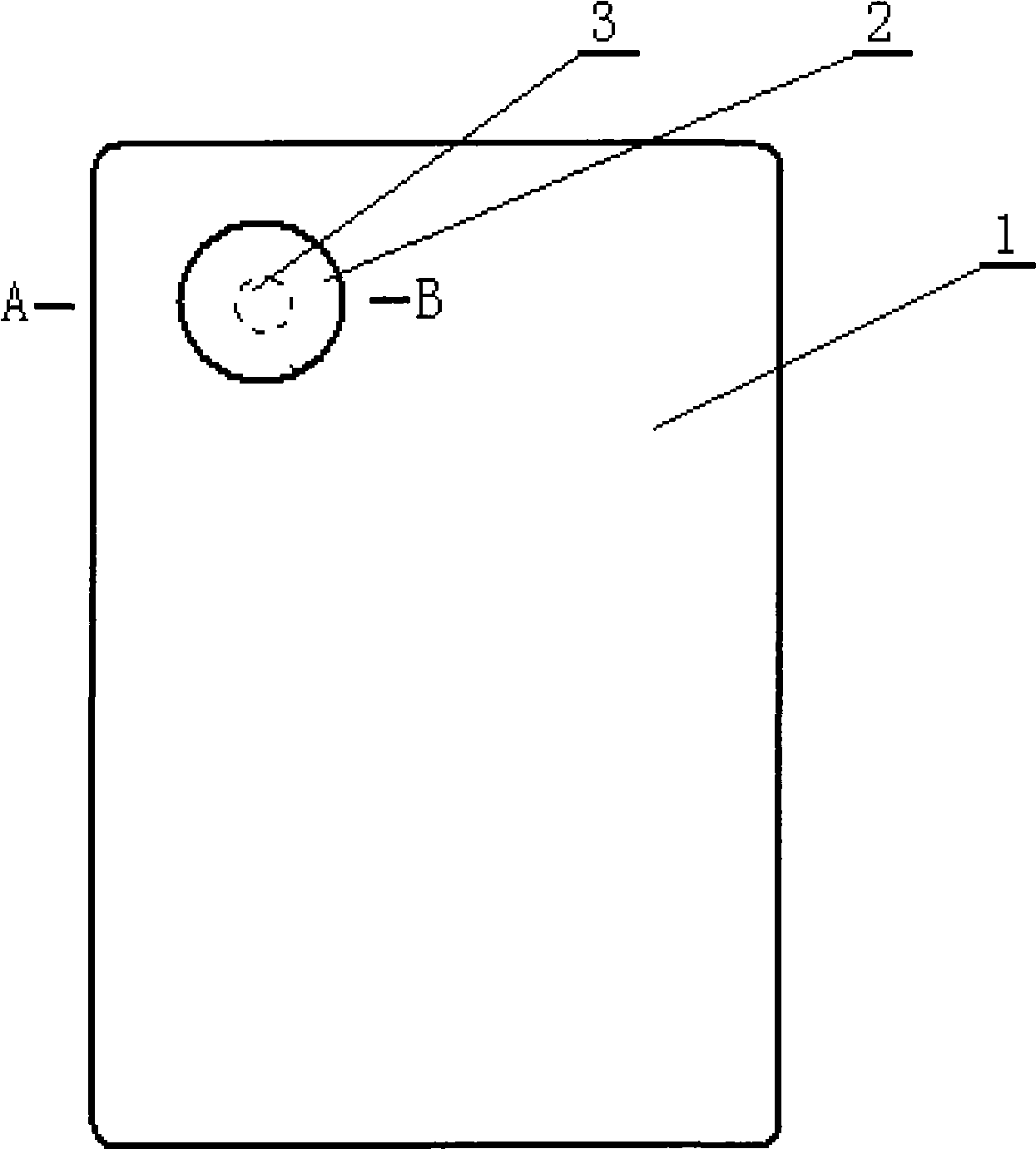

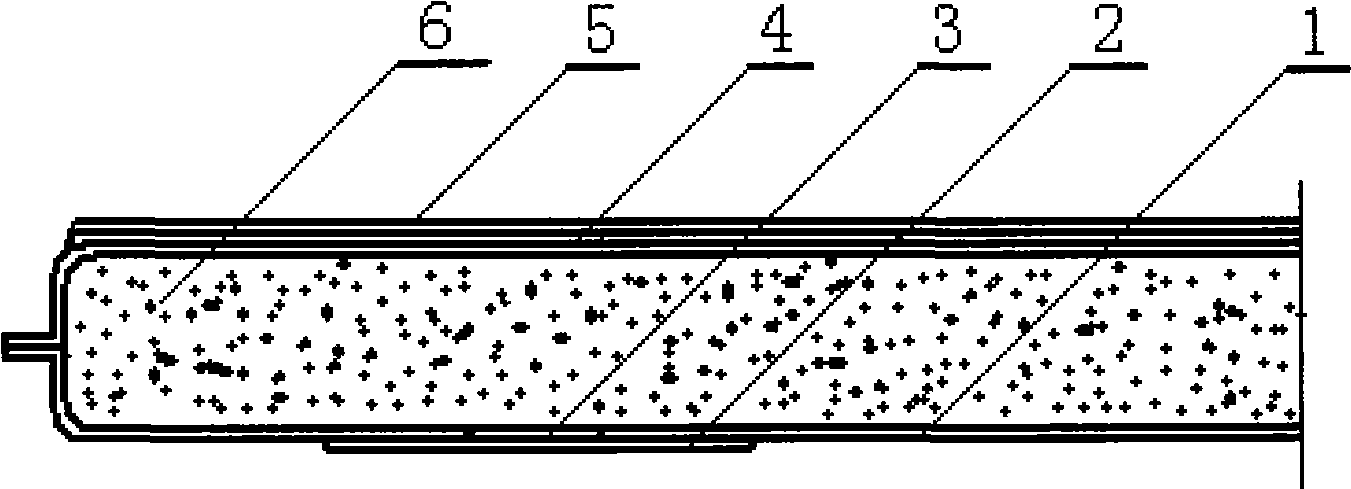

[0014] Embodiment 1: According to figure 1 , figure 2 Shown, among the figure 1 is a bag, made of high-temperature-resistant aluminized plastic, the length of the bag 1 is 16 centimeters, and the width is 12 centimeters. There is a plastic film protective layer 5 with a self-adhesive layer, and a water injection hole 3 is opened on the front, which is sealed with a self-adhesive plastic film 2; a heat-generating material 6 is packaged in the bag body 1, and the raw material weight percentage of the heat-generating material is composed of:

[0015] Magnet powder 35%, salt powder 13%, gac powder 35%, blue lime flour 3%, wood flour 3%, vermiculite powder 8% and wheat flour 3%, weight is 75 grams. When using, first uncover the self-adhesive plastic film covering the water injection hole on the front of the hot compress, inject 15 ml of clear water into the belt through the water injection hole, and then seal it with the self-adhesive plastic film, and at the same time turn it ov...

Embodiment 2

[0016] Embodiment 2: According to Embodiment 1, wherein the raw material weight percentage composition of heating material is:

[0017] Magnet powder 25%, salt powder 5%, gac powder 40%, blue lime flour 6%, wood flour 6%, vermiculite powder 8% and wheat flour 5%, weight is 60 grams.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com