Polystyrene picture frame/frame, application and technology of polystyrene in manufacturing picture frame/frame

A polystyrene and expandable polystyrene technology, applied in the direction of picture frame, application, frame, etc., can solve the problems of high packaging and transportation cost, difficult processing, high material/processing cost, and reduce packaging costs and materials. The effect of low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

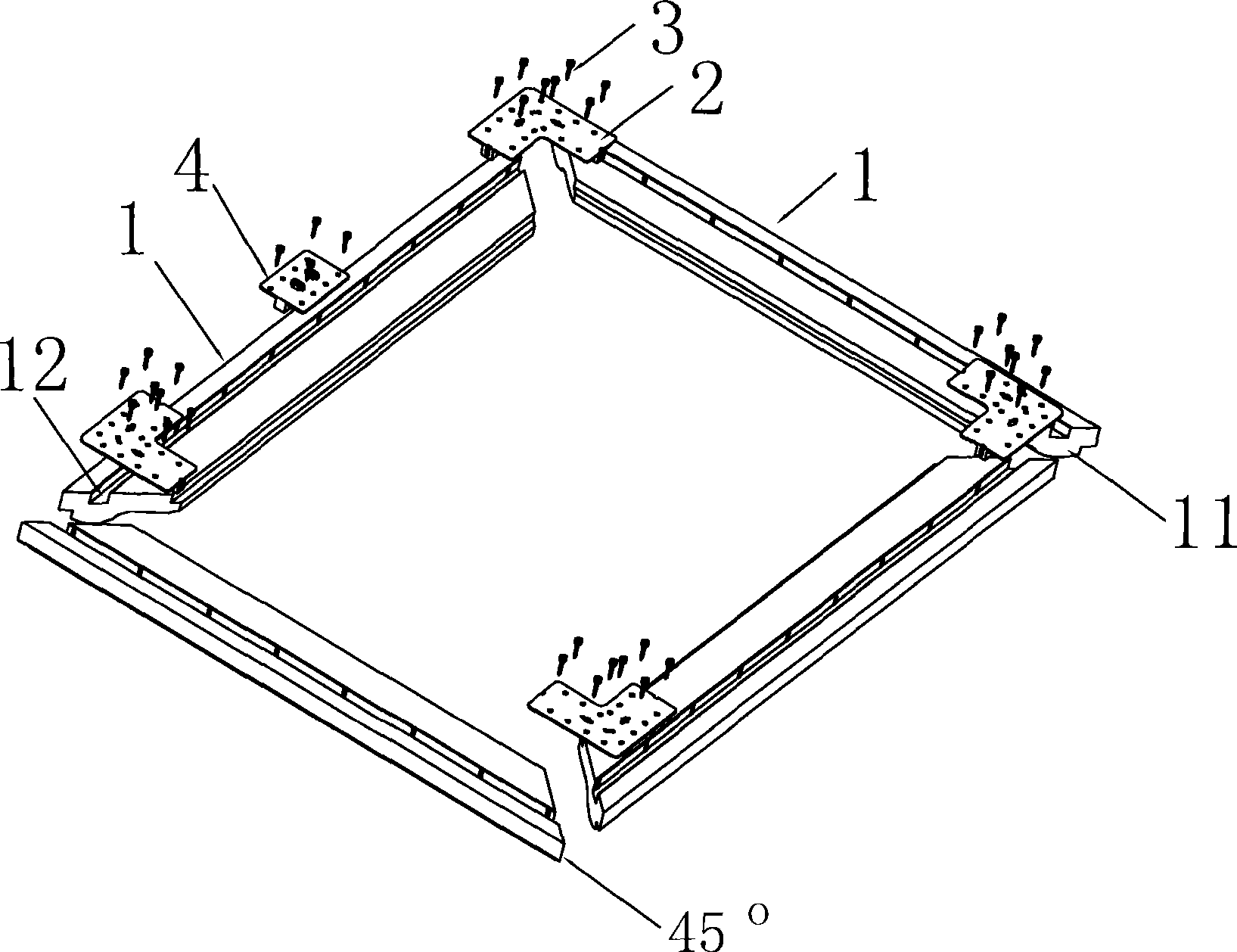

[0028] The present invention will be further detailed below in conjunction with the accompanying drawings:

[0029] This embodiment provides an application of polystyrene in making picture frames / photo frames.

[0030] The manufacturing process of the polystyrene frame / photo frame includes:

[0031] (1) Low-expand expandable polystyrene material into granular form;

[0032] (2) Use a high-pressure gun to inject the foamed particles into the mold, and heat the steam to expand the particles to fill the cavity and fuse the particles into a frame;

[0033] (3) Use the heating wire to cut the frame edge with a standard 45° angle and hypotenuse;

[0034] (4) Use corner codes to connect four frame edges to form a square picture frame / photo frame, or apply water glue to connect the processed frame edges to form a picture frame / photo frame.

[0035] See figure 1 As shown, the polystyrene picture frame / photo frame includes a frame edge 1 with a hypotenuse end with an inner angle of 45°, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com