Functional polymer for enhanced oil recovery

A polymer and functional technology, applied in drilling compositions, production fluids, earthwork drilling, etc., can solve the problems of undisclosed use of polymer surfactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0163] Embodiment 1.FPS embodiment is carried out by general experimental method, comprises following analysis:

[0164] 1) Analyze phase behavior by techniques known in the art (see references below)

[0165] a. Reed, R.L. and Healy, R.N.: "Some Physicalchemical Aspects of Microemulsion Flooding." Improved Oil Recovery by Surfactant and Polymer Flooding (D.O. Shahand R.S. Schechter, Eds), Academic Press, New York, New York (1977) 383-437.

[0166] b. Healy, R.N. and Reed, R.L.: "Physicochemical Aspects of Mictoremulsion Flooding," Transactions, AIME, Volume 257 (1974) 491-501.

[0167] c. Dreher, K.D. and Jones, S.C.: "An Approach to the Design of Fluids for Microemulsion Flooding," Solution Chemistry of Surfactants, Volume 2 (K.L. Mittal Editor), Plenum Publishing Corporation (1979).

[0168] d. Healy, R.N., Reed, R.L., and Stenmark, D.G.: "Multiphase Microemulsion Systems," Transactions, AIME, Volume 261 (1976) 147-160.

[0169] e. Nelson, R.C. and Pope, G.A.: "Phase Rela...

Embodiment 2

[0176] Six demonstration samples of FPS were synthesized by free radical initiated copolymerization (see Table 1).

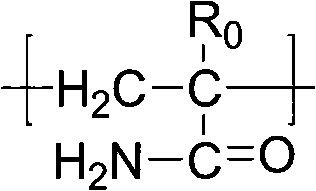

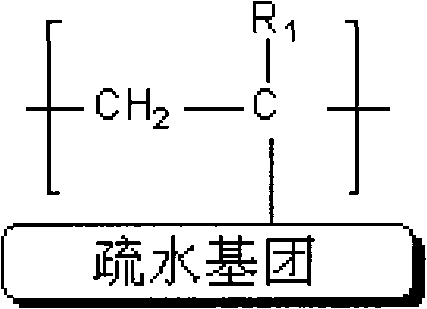

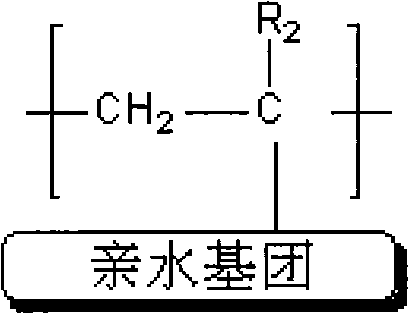

[0177] In the first step, according to the monomer ratio in Table 1, add acrylamide, hydrophilic monomer, lipophilic monomer and sodium carbonate in a three-necked round bottom flask, dissolve in deionized water to form a solution, then add sodium formate and ammonia. The total mass of all reactants accounted for 25-30% of the total mass of the solution in the flask.

[0178] In the second step, the flask was placed in a water bath, and deoxygenated by nitrogen for 20 minutes. Under the protection of nitrogen, put the initiation system including azo initiator (such as ABIN), reducing agent (such as sodium bisulfate) and oxidizing agent (such as sodium persulfate) into the flask. The total mass of the initiation system accounts for 0.01%-0.1% of the mass of all reactants.

[0179]In the third step, the flask was deoxygenated under nitrogen for an additional 10...

Embodiment 3

[0209] Coreflood testing was performed on 12-inch cores of epoxy-coated Bere Sandstone (average air permeability 487md) at 185F. The dry core was flushed with 2 pore volumes of concentrated brine until irreducible water saturation was reached, yielding a typical crude oil with a viscosity of about 7.2 cP. The oil saturation is typically 0.65. The core was flushed again with the same concentrated brine until a residual oil saturation (98% water cut) between about 0.42 and 0.65 was reached.

[0210] Chemical flooding was started by injecting 0.3 pore volume of 1500ppm FPS sample (using FPS-1a, 1b, 1c, 2a, 2b, 2c in 6 core displacement tests, respectively) slug, which was prepared by 0.5% NaCl brine preparation. Then inject 0.5% sodium chloride brine until the residual oil saturation (water content 98%) is reached. The resulting residual oil saturation is listed in Table III.

[0211] Another chemical flood was started by injecting 0.3 pore volume of 1500 ppm PAM-25 (polyacry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com