Bismuth-base glass composition and bismuth-base material

A technology of bismuth-based glass and composition, which is applied in the manufacture of electrode system, exhaust connection/feeding, cathode ray/electron beam tube shell/container, etc. Solve problems such as filling and analysis, and achieve the effect of ensuring the reliability of airtightness and the thermal expansion coefficient is not easy to change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

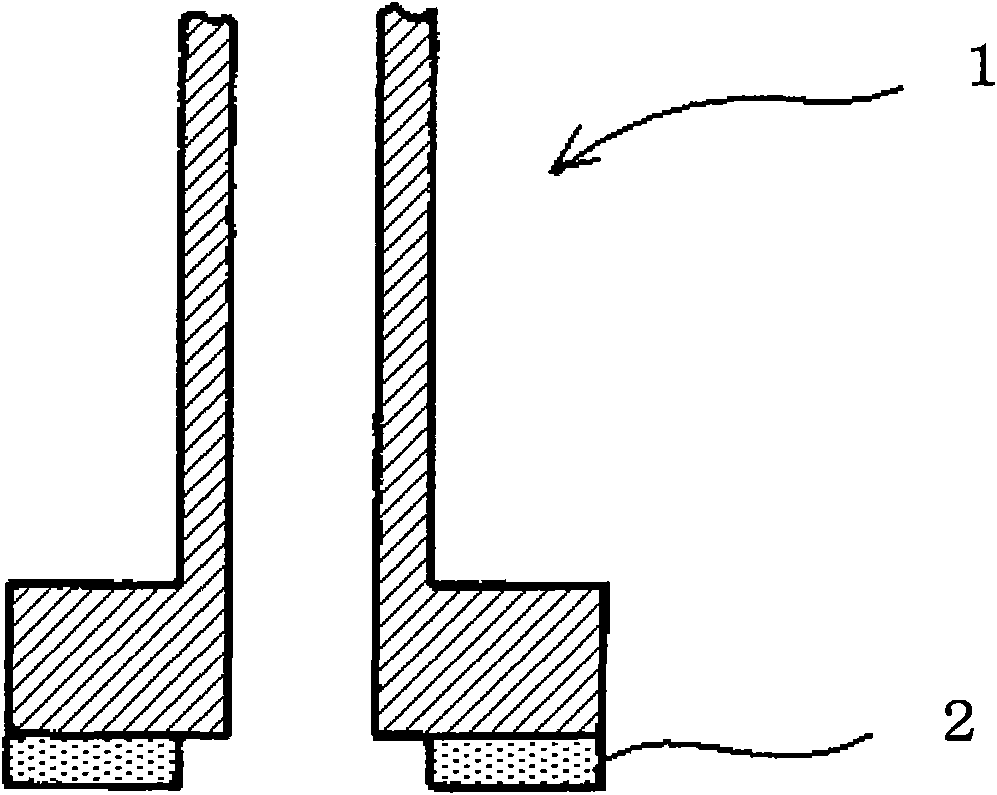

Image

Examples

Embodiment Construction

[0036] In the bismuth-based glass composition of the present invention, the reason for limiting the glass composition range as described above is as follows. In addition, the following % shows mass % except the case where it is specifically limited.

[0037] Bi 2 o 3 It is a main component for lowering the softening point of glass, and it is also a component that becomes a structural component of precipitated crystals. Its content is 60-84%, preferably 65.1-79.9%, more preferably 67-79.3%, further preferably 72-77%, especially preferably 75-less than 77%. If Bi 2 o 3 If the content of Al is less than 60%, the softening point will rise, and it will be difficult to seal at a temperature below 500°C. If Bi 2 o 3 If the content of α is greater than 84%, the devitrification resistance of the glass will deteriorate, and before softening in the sealing process, crystals will precipitate on the glass, making it difficult to function as a sealing material.

[0038] B 2 o 3 It...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com